Differential confocal fixed surface interference target shot inner surface defect detection method and device

A defect detection and differential confocal technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as direct and precise detection of inner surface defects that are difficult to achieve precise focusing of the target capsule, and achieve the expansion of the effective measurement field of view and direct focusing Imaging is direct, the effect of improving measurement accuracy and measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with drawings and embodiments.

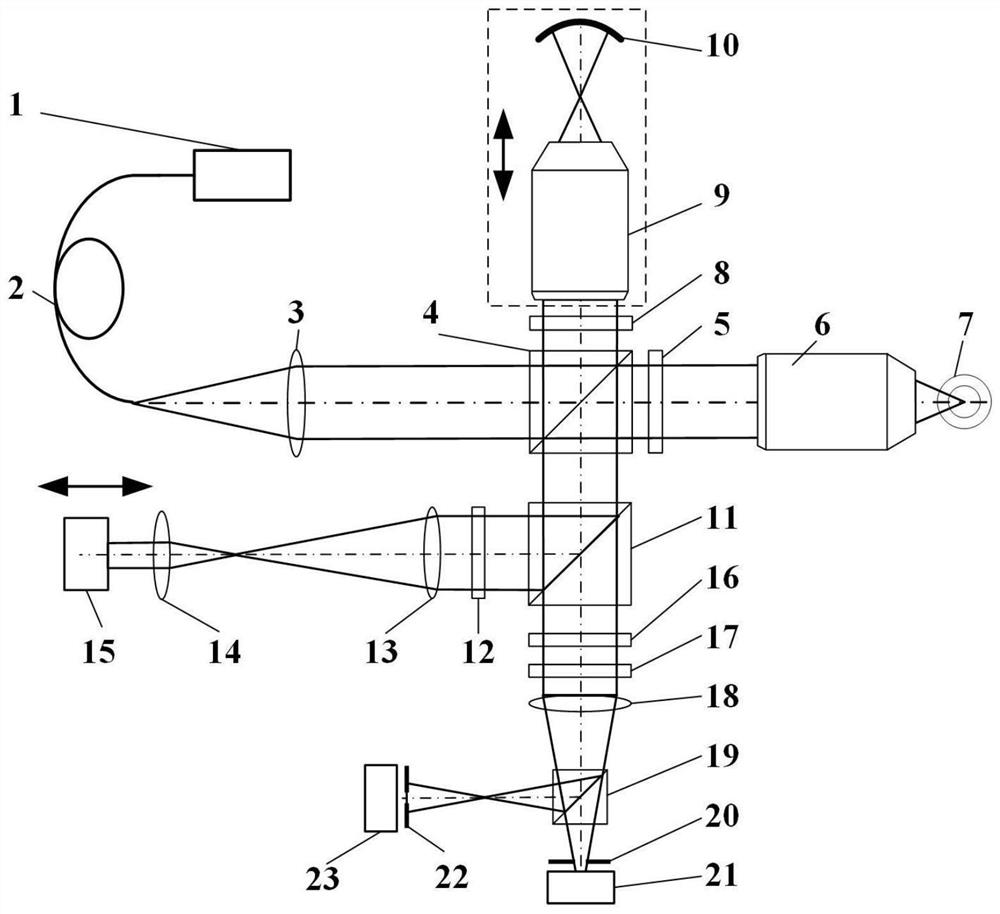

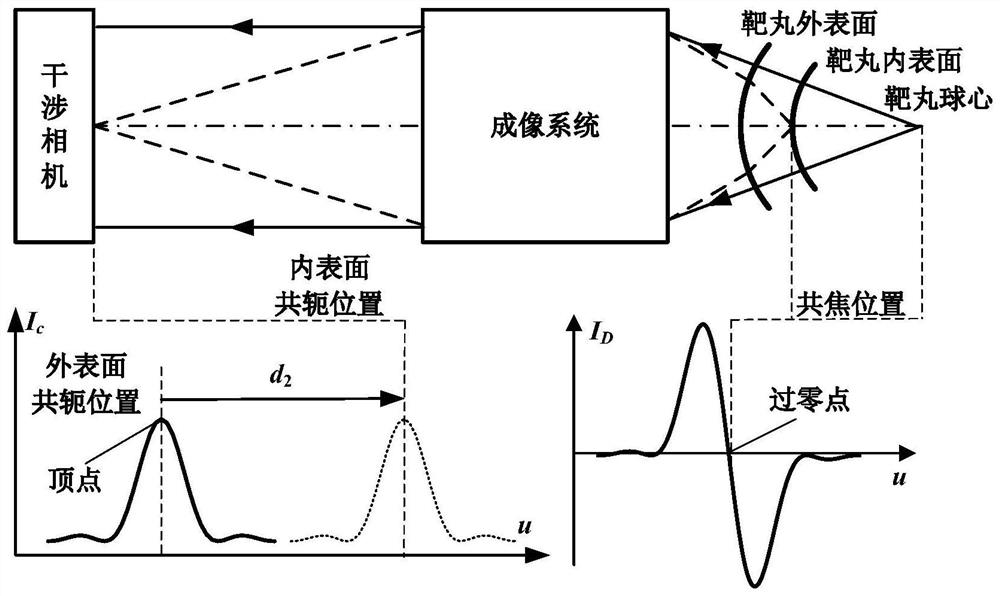

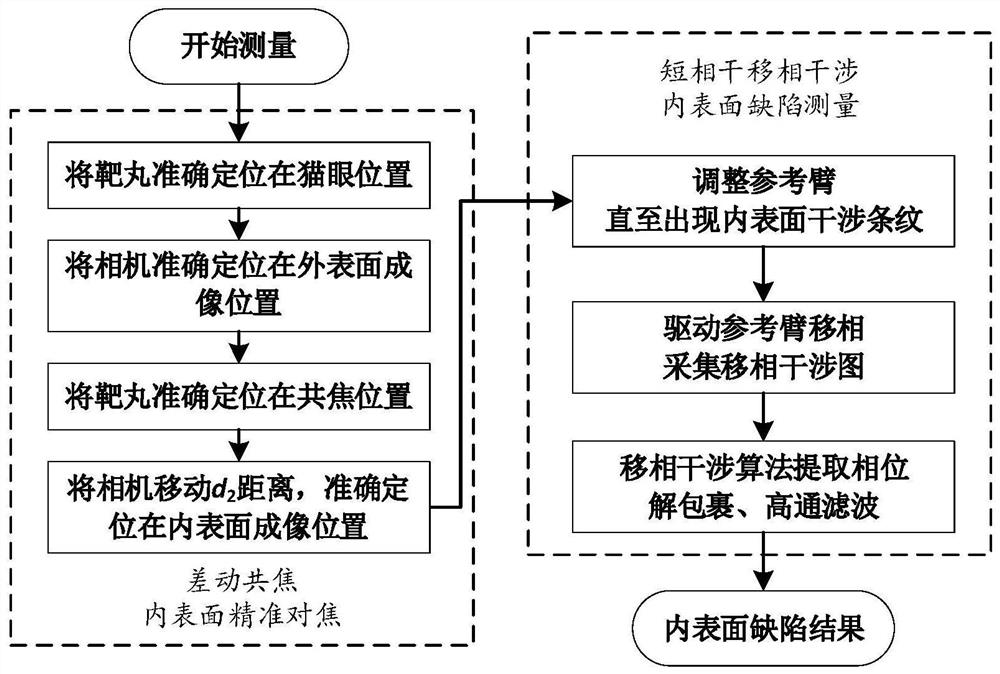

[0056] combine Figure 1-Figure 6 , the detection method and detection device of the inner surface defect of the differential confocal fixed surface interference target, wherein the short coherent linearly polarized light emitted by the short coherent laser 1 is coupled into one end of the optical fiber 2, and the light emitted by the other end of the optical fiber 2 is collimated by a collimator 3. Collimated into parallel light, the parallel light is divided into two paths by PBS4, the light beam passing through PBS4 passes through the first quarter-wave plate 5 and the measurement objective lens 6, and then converges at the spherical center of the target ball 7 to be measured. The light beam reflected by the surface passes through the first quarter-wave plate 5 and the measurement objective lens 6 again to form measurement light. The light beam reflected by PBS4 pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com