Ultra-smooth dual-band reflector and preparation method thereof

A dual-band, ultra-smooth technology, applied in the field of mirrors, can solve the problems of lens surface deformation, reflectivity reduction, film oxidation, etc., and achieve the effects of reducing surface temperature, reducing scattering, and improving adhesion

Active Publication Date: 2021-04-20

CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

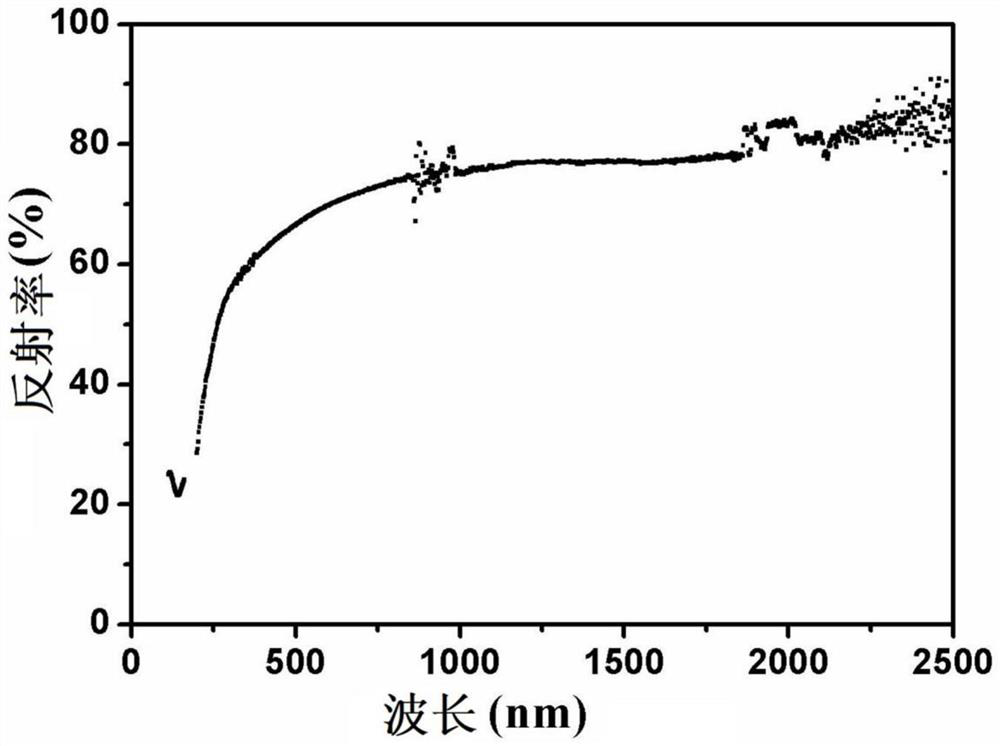

[0004] The SCORE coronal observation payload developed in Italy uses a Mo / Si multi-layer mirror with a high-frequency roughness of about 0.5nm, which will cause severe large-angle scattering; the reflectivity in the visible light band is low, and the absorption rate is 57%. Left and right, in the case of direct sunlight, the lens temperature will exceed 50°C, which will cause the lens surface to deteriorate; no matter whether the last layer of the Mo / Si multilayer mirror is Mo or Si, in the harsh space environment (atomic Oxygen, high-energy protons, electrons, high-energy rays, ultraviolet light), the oxidation of the film layer will occur, resulting in a decrease in the reflectivity at 121.6nm

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

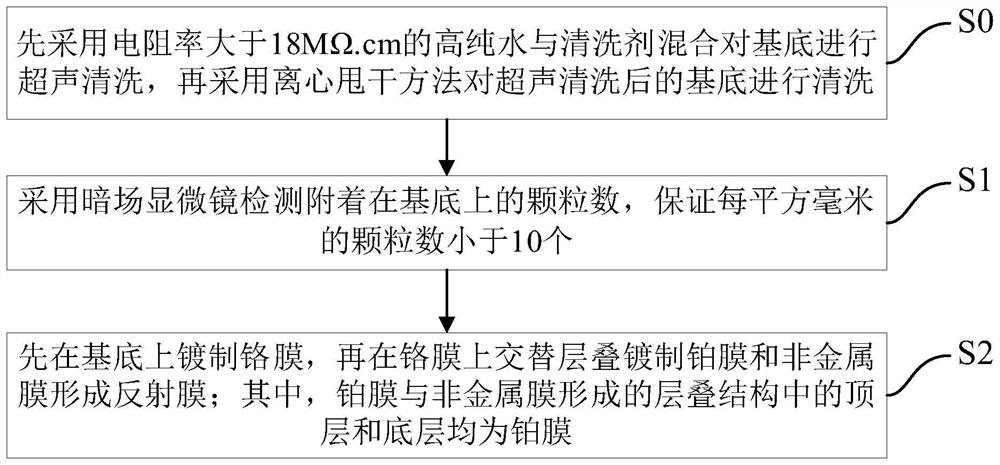

[0049] Such as figure 2 As shown, the preparation method of the ultra-smooth dual-band reflector provided by the embodiment of the present invention includes the following steps:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

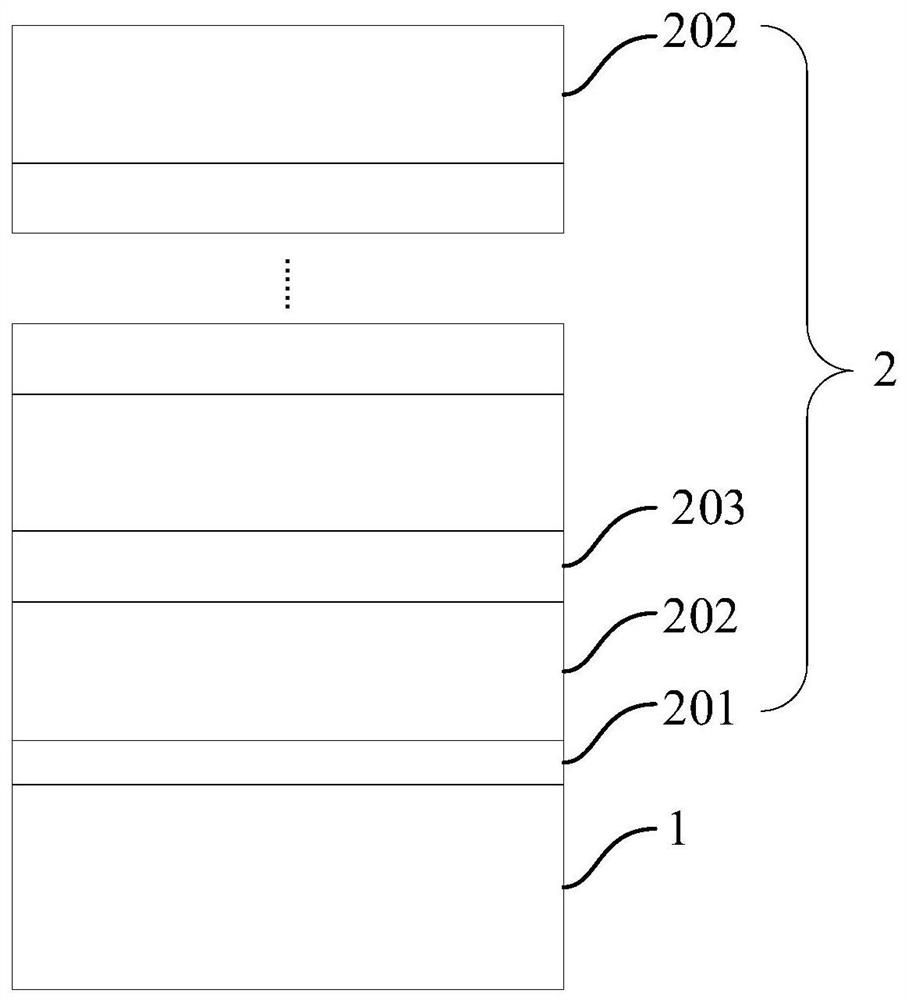

The invention provides an ultra-smooth dual-band reflector and a preparation method thereof. The ultra-smooth dual-band reflector comprises a substrate and a reflecting film plated on the substrate, the reflecting film is composed of platinum films and non-metal films which are alternately stacked through metal, the metal films comprise chromium films and platinum films, the chromium films are plated on the substrate, the platinum films and the non-metal films are alternately laminated and plated on the chromium films, the top layer and the bottom layer in the laminated structure formed by the platinum films and the non-metal films are chromium films, the thickness of each chromium film is 1 to 3nm, the thickness of each platinum film is 5 to 30nm, the thickness of each non-metal film is 1 to 100nm, and the total thickness of the reflecting film is 100 to 300nm. According to the invention, the low high-frequency roughness and the low intermediate-frequency roughness can be ensured, the reflectivity to an imaging waveband is high, the space environment irradiation resistance is high, the space adaptability is good, and the performance is stable.

Description

technical field [0001] The invention relates to the technical field of reflecting mirrors, in particular to an ultra-smooth dual-band reflecting mirror and a preparation method thereof. Background technique [0002] In coronal imaging detection, since the light intensity on the solar surface is much higher than the coronal light intensity, stray light suppression is the focus and difficulty in the development of coronagraphs. At present, there are mainly two kinds of coronal imaging optical systems: internal cover type and external cover type. The main mirror in the built-in imaging optical system directly faces the sunlight, and its scattering is the main source of stray light. Therefore, in addition to requiring the main reflector to have high reflectivity in the imaging band (121.6nm and visible light band), the main reflector is also required to have an ultra-smooth surface (roughness better than 0.3nm). To get an ultra-smooth mirror, you first need an ultra-smooth sub...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G02B5/08C23C14/35C23C14/46C23C14/16C23C14/18C23C14/06

Inventor 王孝东陈波任帅周鹏王海峰

Owner CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com