Permanent magnet stator coreless axial magnetic field permanent magnet motor

A permanent magnet stator, axial magnetic field technology, applied in electrical components, electromechanical devices, magnetic circuit static parts, etc. The effect of less dosage, lower system cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

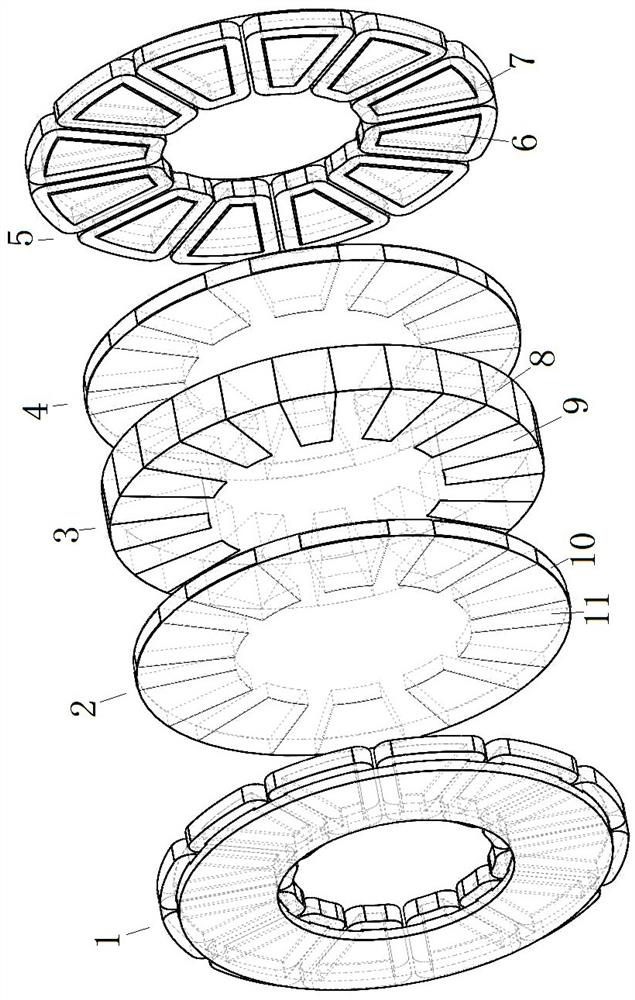

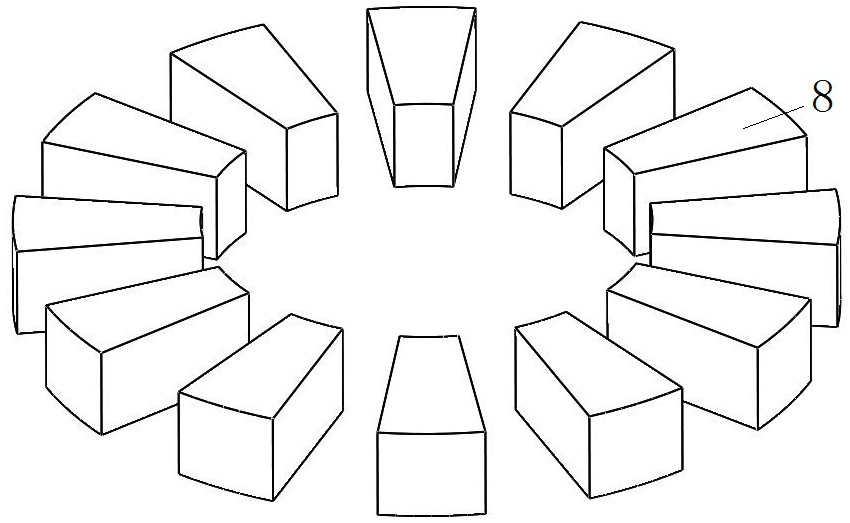

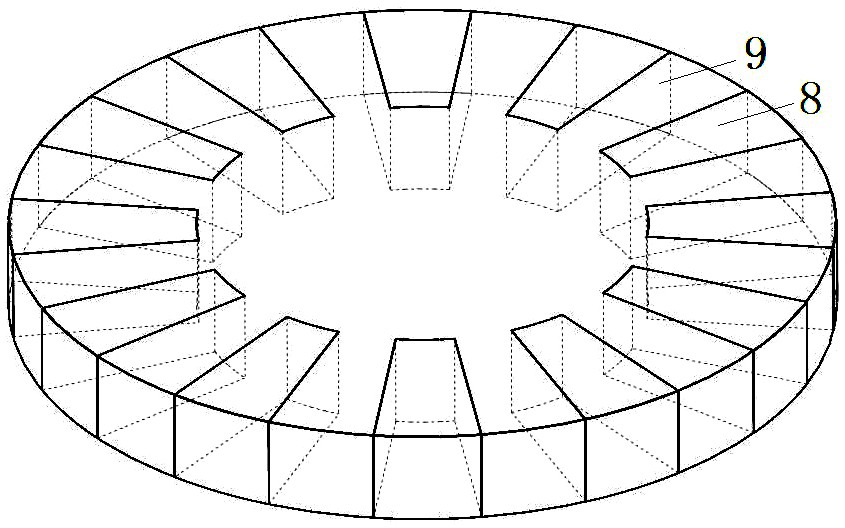

[0014] Such as Figure 1~3 As shown, a permanent magnet stator coreless axial field permanent magnet motor includes two armature stators, a middle permanent magnet stator and two rotors, two armature stators, a permanent magnet stator and two rotors according to the An armature stator 1, a first rotor 2, a permanent magnet stator 3, a second rotor 4, and a second armature stator 5 are sequentially arranged coaxially along the axial direction, and the first armature stator and the second armature stator are identical and placed symmetrically, the first rotor and the second rotor are identical and placed symmetrically, the armature stators both include armature stator cores 6 and armature windings 7, and the permanent magnet stators include high coercive The for...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap