Sensor fault comprehensive diagnosis and ride-through method of modular multilevel converter

A modular multi-level, sensor fault technology, applied in the direction of measuring electrical variables, converting AC power input to DC power output, instruments, etc., can solve the problems of fault diagnosis and fault ride-through without MMC sensors, and achieve stable operation, Fast diagnosis, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It is obvious that those skilled in the art can easily make various modifications to the above-mentioned embodiments, and apply the general principles described here to other embodiments without creative efforts. Therefore, the present invention is not limited to the above embodiments, and improvements and modifications made by those skilled in the art according to the disclosure of the present invention should fall within the protection scope of the present invention.

[0029] This embodiment provides a method for locating submodule faults of modular multilevel converters based on correlation analysis, including the following steps:

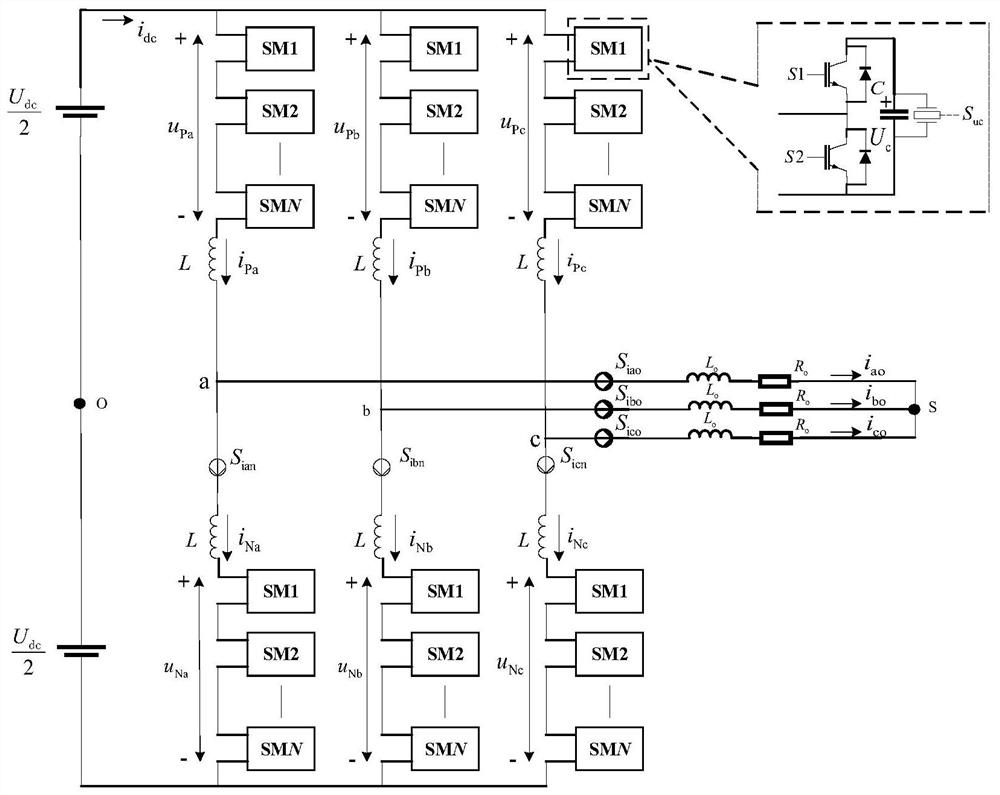

[0030] (1) Establish a sensor feedback system under normal operating conditions according to the MMC topology;

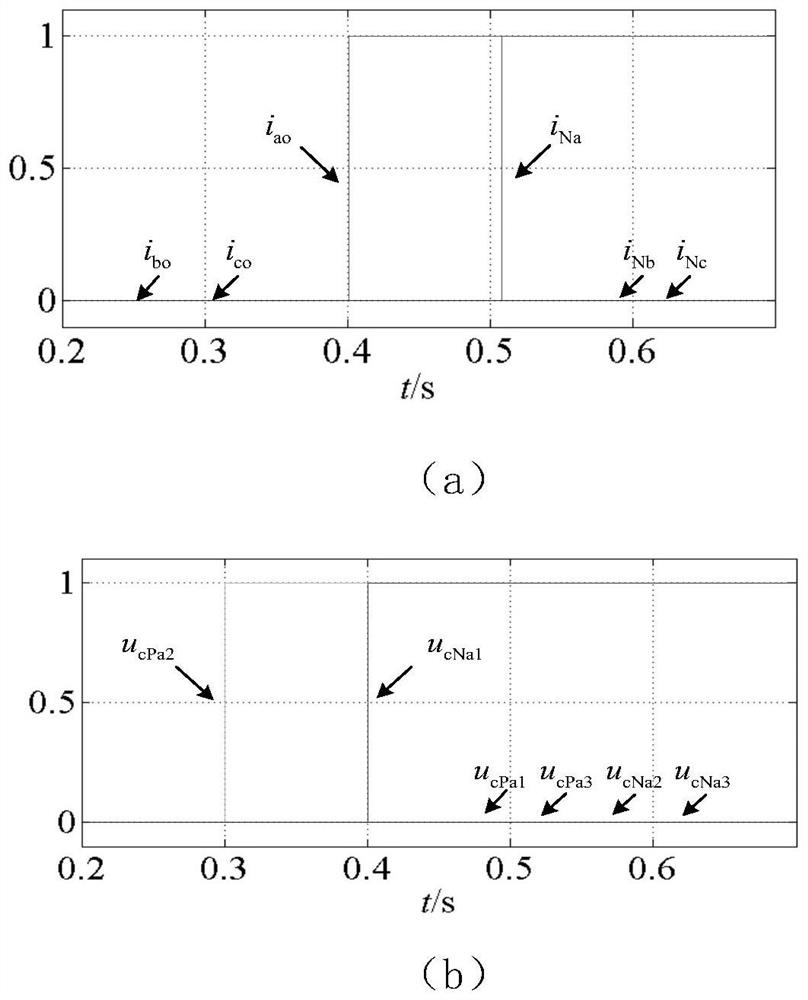

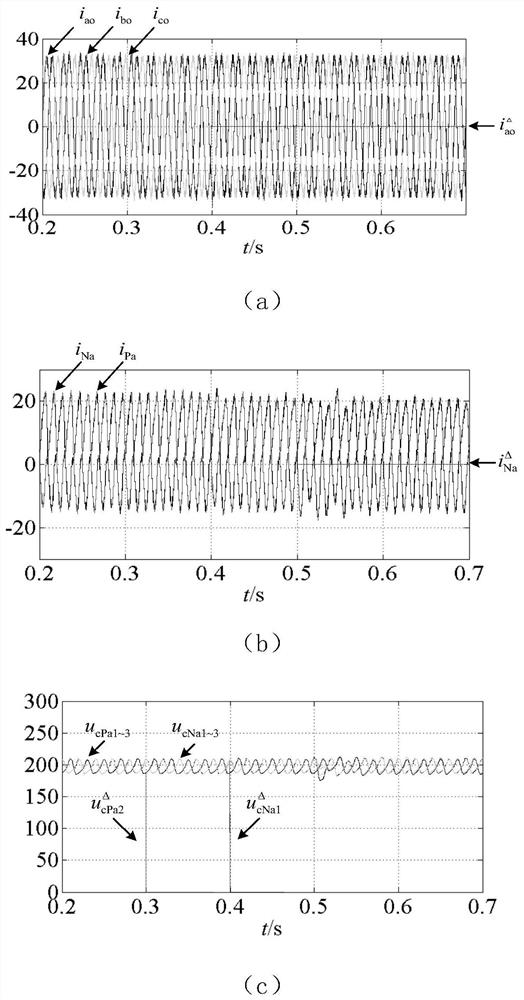

[0031] (2) Diagnose the fault location of the current sensor on the AC side and perform fault ride-through; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com