Non-contact sensor switch based on Hall and logic magnetic coding technology

A non-contact, magnetic encoding technology, which is applied in electronic switches, pulse technology, relays, etc., can solve the problem of low confidentiality level of magnetic encoding sensors, and achieve the effect of capturing signals at a good position, high electromagnetic compatibility, and ensuring equipment safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

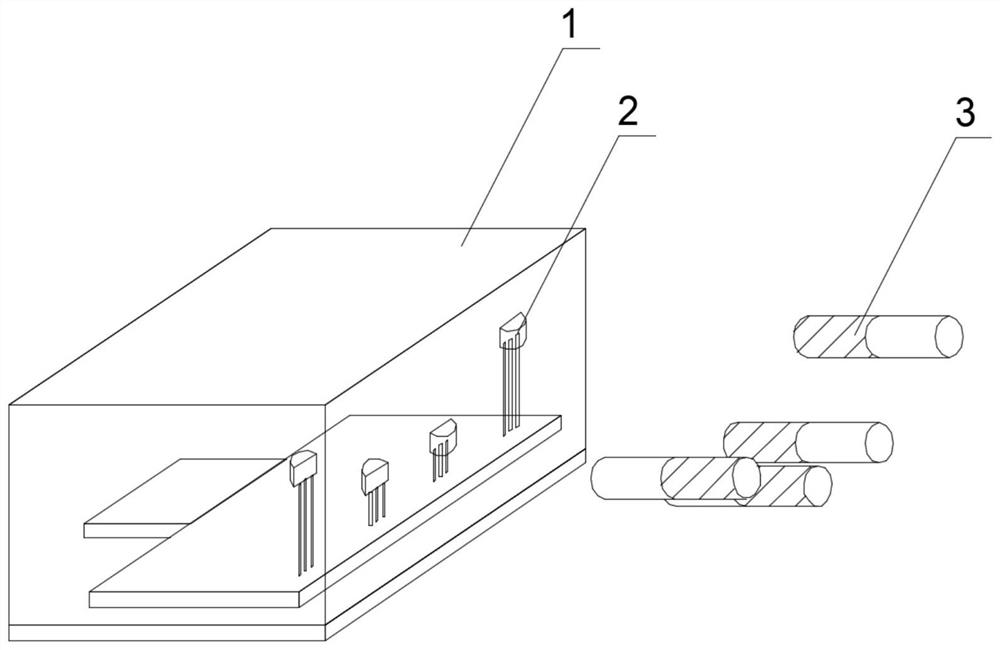

[0024] refer to figure 1 , a non-contact sensor switch based on Hall and logic magnetic encoding technology, including a non-contact sensor circuit and its packaging shell 1, the non-contact sensor circuit includes a relay, the relay includes a control coil input terminal and normally open and normally open Closed contact output terminal, the non-contact sensor circuit controls the relay to be turned on or off through an AND operation logic circuit and a NOT gate circuit based on N single-stage Hall elements 2, and the AND logic operation circuit passes The N single-stage Hall elements 2 form a logic magnetic code according to the magnetic pole direction, position and quantity, and the input end of the AND logic operation circuit is provided with a power input polarity protection circuit.

[0025] While working, refer to figure 1 After encapsulating the sensor switch through the shell 1, use the same number as the single-stage Hall element 2, and the magnet 3 corresponding to...

Embodiment 2

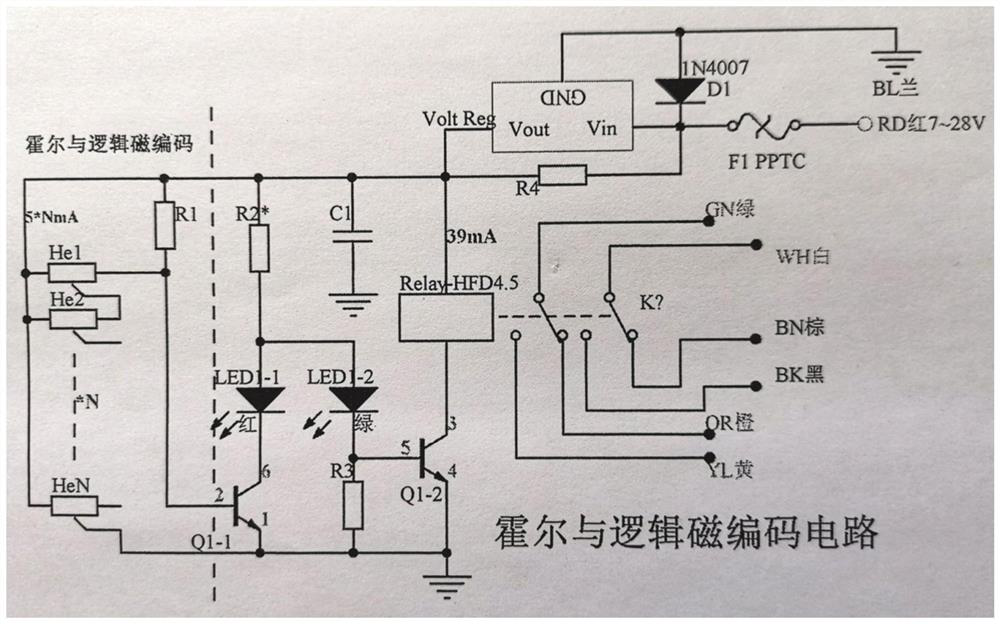

[0027] refer to figure 2 , a non-contact sensor circuit, the non-contact sensor circuit includes a single-stage Hall element He, a composite transistor Q1-1, a composite transistor Q1-2, a pull-up resistor R1, a pull-up resistor R2, a pull-down resistor R3, a filter capacitor C1, Diode D1, self-recovery insurance device F1, voltage regulator; the self-recovery insurance device F1 and diode D1 form a power supply input polarity protection circuit, and current limiting protection is performed through the voltage regulator; the NOT gate circuit is composed of the The composite transistor Q1-1 and the composite transistor Q1-2 are composed, the base of the composite transistor Q1-1 is connected to the pull-up resistor R1, and the base of the composite transistor Q1-2 is connected to the pull-down resistor R3 , the collector of the composite transistor Q1-1 and the base of the composite transistor Q1-2 are connected to the pull-up resistor R2, the emitter of the composite transist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com