Weaving, dyeing, sizing and washing processing oil-containing waste gas purification and waste heat comprehensive utilization system and method

A waste gas purification and waste heat technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve problems such as explosions, achieve the effects of preventing explosions, reducing cost requirements, and ensuring safe processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

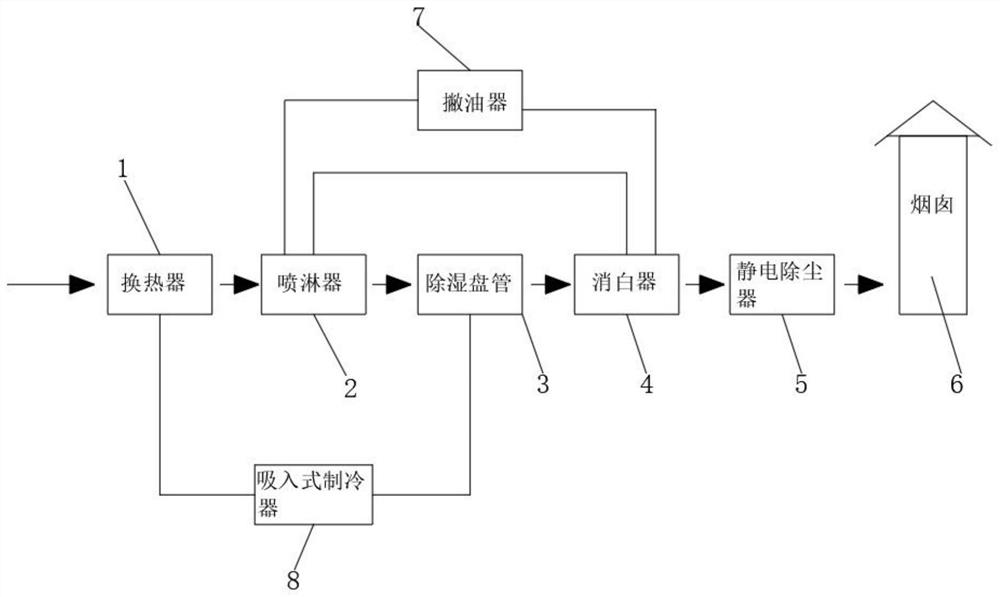

[0026] Such as figure 1 As shown, the embodiment of the present invention provides a system for purifying oily waste gas and waste heat in weaving and dyeing pulp washing and comprehensive utilization system, including heat exchanger 1, shower 2, dehumidification coil 3, whitening device 4, electrostatic precipitator 5, and chimney 6. Oil skimmer 7, refrigerator 8, heat exchanger 1 is connected with sprinkler 2, sprinkler 2 is connected with dehumidification coil 3, dehumidification coil 3 is also connected with whitening device 4, whitening The device 4 is connected with the electrostatic precipitator 5, the electrostatic precipitator 5 is also connected with the chimney 6, the oil skimmer 7 is connected with the sprayer 2 and the whitening device 4 respectively, and the oil skimmer 7 is respectively connected to the sprayer 2 and the The oil in the treatment process of the dewhitening device 4 is skimmed and collected, thereby generating new economic benefits.

[0027] One ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com