Stamping device for automobile exhaust pipe

A stamping device, automobile exhaust technology, applied in the field of exhaust pipe stamping, to achieve the effect of convenient cutting and polishing, and improve the effect of cutting and polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

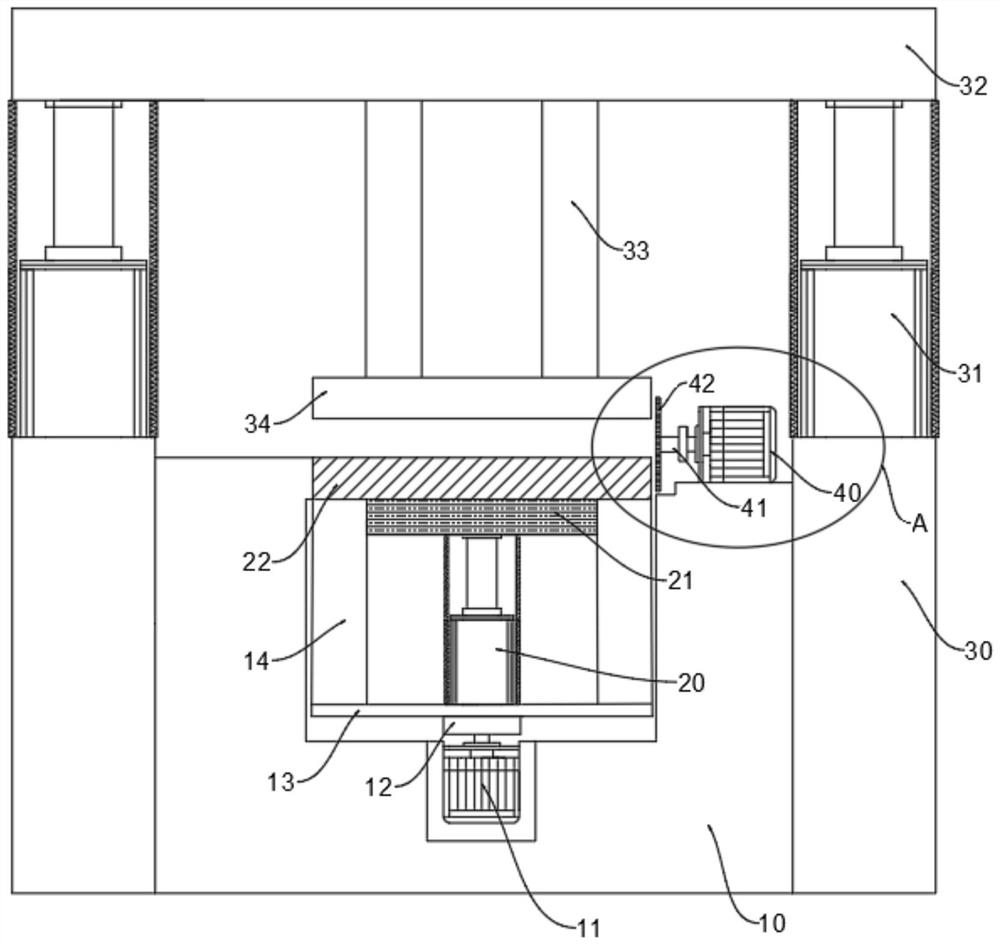

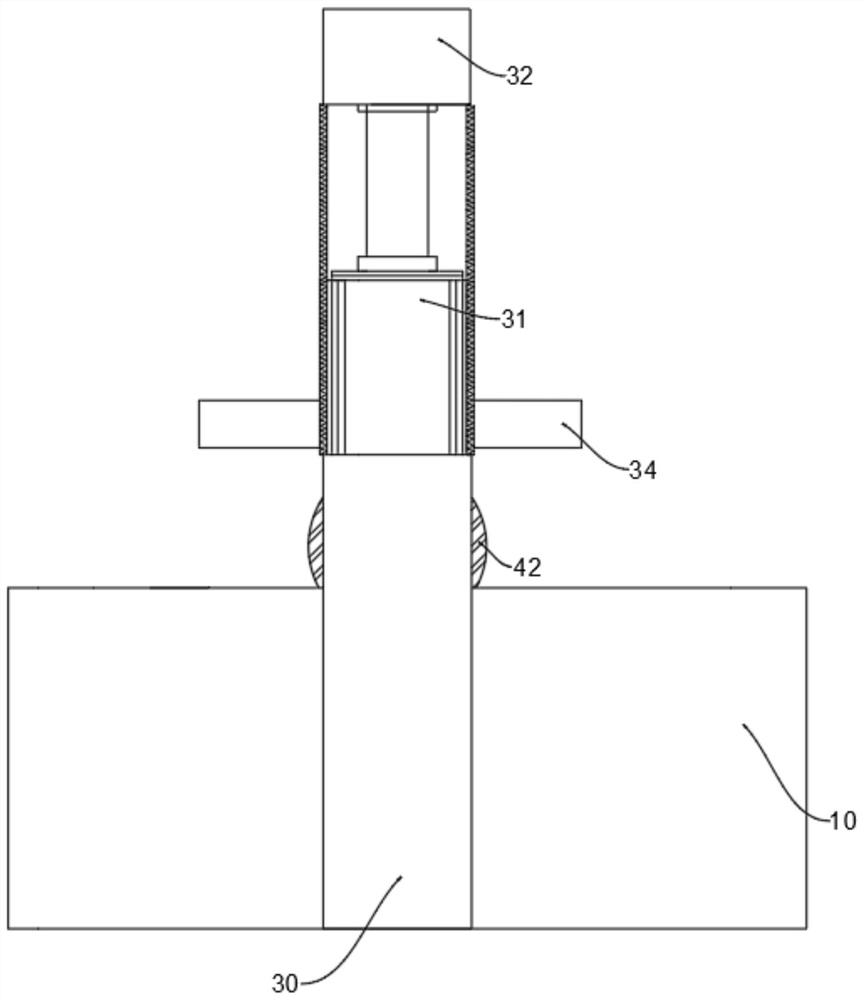

[0026] Such as Figure 1~3 As shown, it is a front view structural schematic diagram of an automobile exhaust pipe stamping device in a preferred embodiment of the present invention. The automobile exhaust pipe stamping device of this embodiment includes a base 10, and the inside of the base 10 is provided with a first Motor 11, the upper end of the first motor 11 is rotatably connected with a bearing 12, the upper end of the bearing 12 is connected with a rotating disk 13, the upper end of the rotating disk 13 is provided with a first hydraulic device 20, and the first The upper end of the hydraulic device 20 is provided with a top plate 21, the vertical centerline of the first hydraulic device 20 coincides with the vertical centerline of the rotating disk 13, the rotating disk 13 is connected with a supporting platform 14, and the supporting platform 14, the inner side surface is connected with the top plate 21, the top plate 21 and the support platform 14 are in a clearance...

Embodiment 2

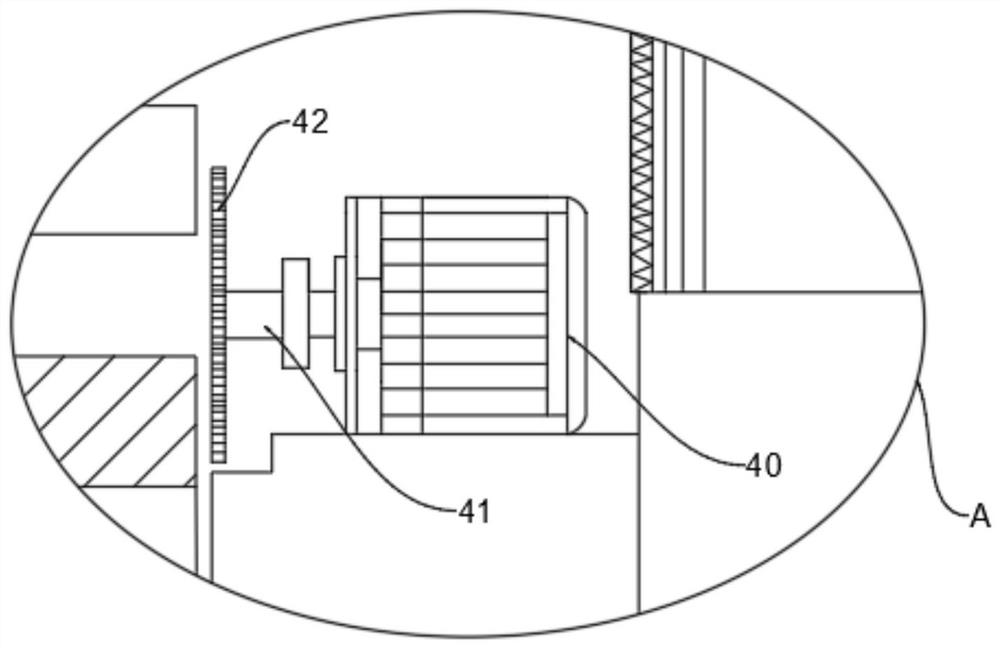

[0031] Such as Figure 4-5 As shown, it is a schematic diagram of a three-dimensional structure of a chute and a work piece in another preferred embodiment of the present invention. On the basis of Example 1, the chute and work shape of the automobile exhaust pipe stamping device of this embodiment The structure of the parts includes a second motor 40, the lower end of the second motor 40 is connected with a work piece 43, and the work piece 43 is slidably connected with a chute 44, and the work piece 43 and the chute 44 There is a gap fit relationship;

[0032] The working principle of the present invention is: the second motor 40 can move along the direction of the inner groove of the chute 44 through the said workpiece 43 and the chute 44, so as to adjust the distance between the sand disc 42 and the flange 22. The distance between them improves the cutting and grinding effect of the sand disc 42 on the extrusion and overflow flash of the flange plate 22.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com