Drilling clamp for duckbilled hammer manufacturing

A fixture and duckbill technology, which is applied in the direction of manufacturing tools, clamping, support, etc., can solve the problems of large manpower consumption, achieve the effect of convenient clamping, reduce drilling process, and small processing error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

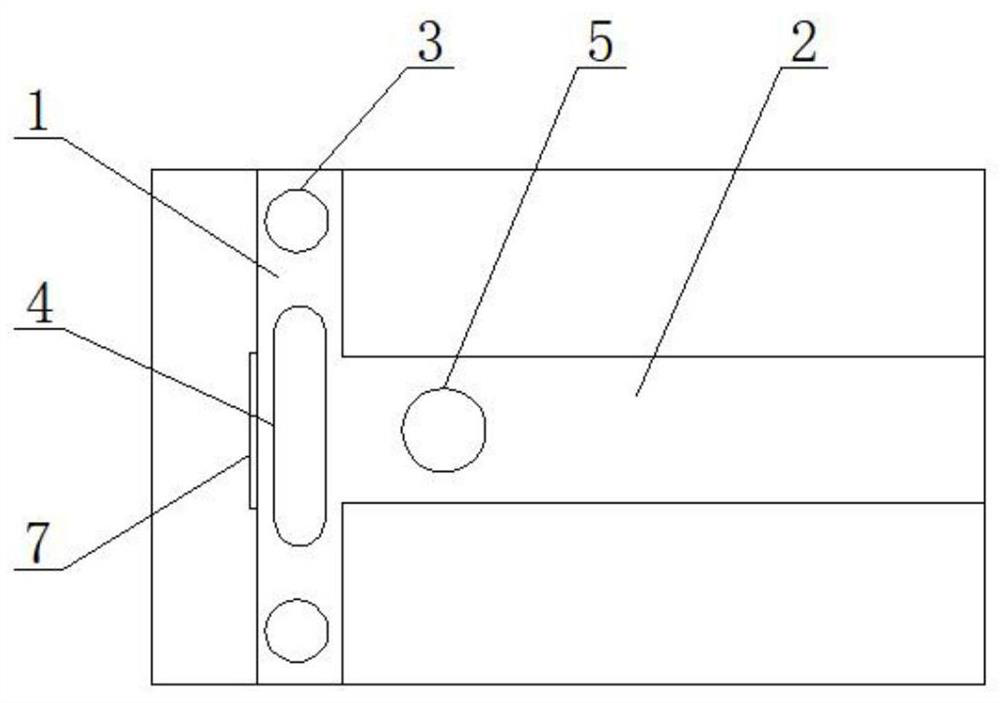

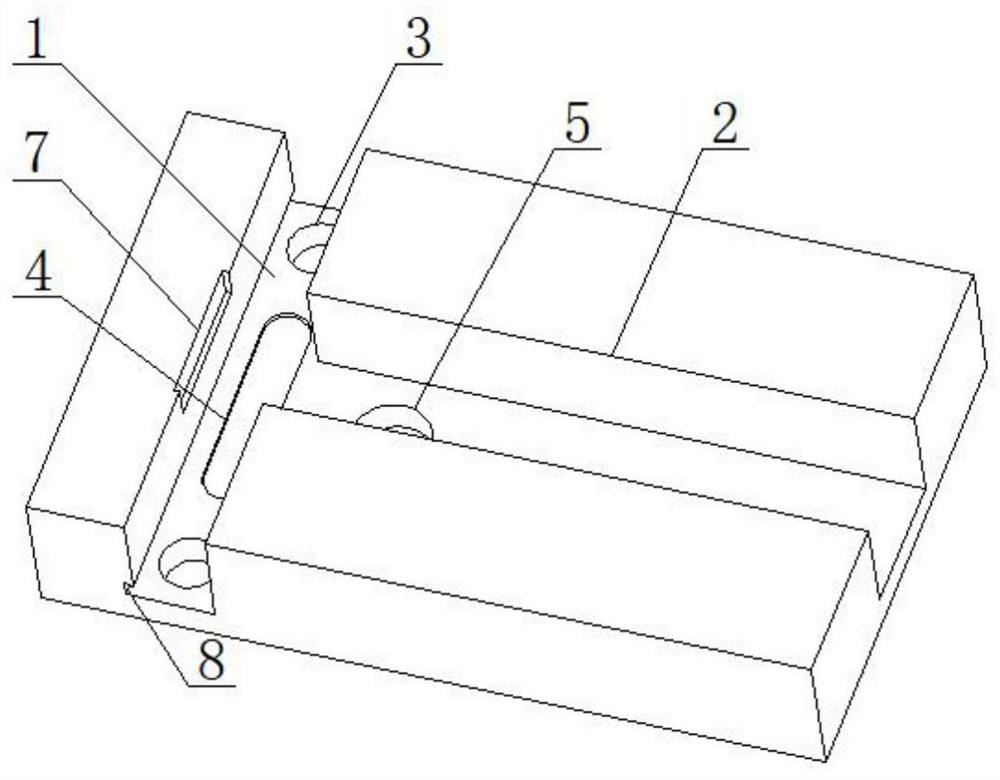

[0039] as attached Figure 1-3 As shown in the main body of the fixture, the main body of the fixture is clamped on the bench vise, and the bench vise is fixed on the drill press, and the drill press is first pressed down so that the center drill is opposite to the positioning hole 5 on the fixture main body, and then fixed; When the main body is fixed in the bench vise, it is often necessary to place a shim on the bottom surface, and the shim should avoid the positioning hole 5; the main body of the fixture in this example is processed by the machining center, and it is necessary to ensure that the center of the positioning hole 5 is at a distance from the chip removal groove. 1 The size of the left side is consistent with the size of the duckbill hammer 6 required by the drawings. The groove width of clamping groove 2 is slightly greater than the width of duckbill hammer 6. Generally, the blank material used in practice is 14mm*14mm*68mm brass square material, which is proc...

Embodiment 2

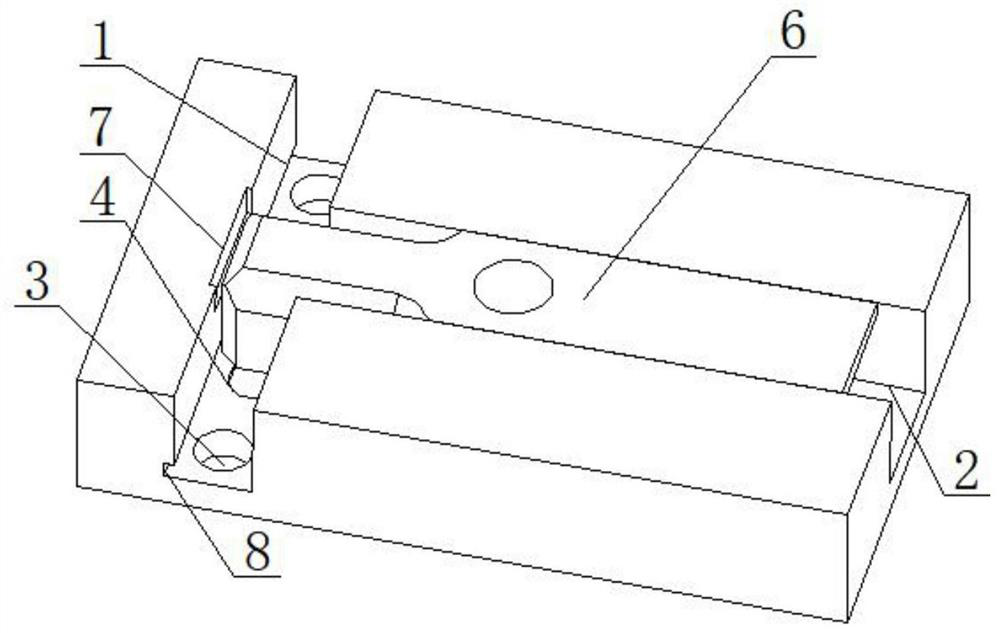

[0045] as attached Figure 4 As shown, compared with the first embodiment, the depth of the chip removal groove 1 of the fixture body in this example is greater than that of the clamping groove 2. The advantage is that it can accommodate more copper chips and reduce the number of cleanings during the center hole machining process.

Embodiment 3

[0047] as attached Figure 5 As shown, compared with the first embodiment, the left side of the clamp body in this example has a threaded groove 9 transversely, and the threaded groove 9 is fitted with a fine-tuning nut 10 , and at the same time, the inclined step 7 and the burr-containing groove 8 can be reduced. The advantage of this example is that when processing the fixture body, it is not necessary to ensure that the center of the positioning hole 5 is the same as the size of the duckbill hammer 6 on the left side of the chip removal groove 1, which is consistent with the size of the duckbill hammer 6 required by the drawing. The distance is greater than the requirements of the drawing, which greatly reduces the production cost. Before use, it is only necessary to adjust the fine-tuning nut 10 through the standard-processed duckbill hammer 6 . In addition, in this example, when processing the blank with an inclined plane, the fine-tuning nut 10 is centered against the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com