Red disperse dye composition, red disperse dye as well as preparation method and application of red disperse dye

A technology of disperse dyes and compositions, applied in the field of dyes, can solve the problems of long process time and excessive sewage, and achieve the effects of reducing dyeing sewage, high color quantity, and easy acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

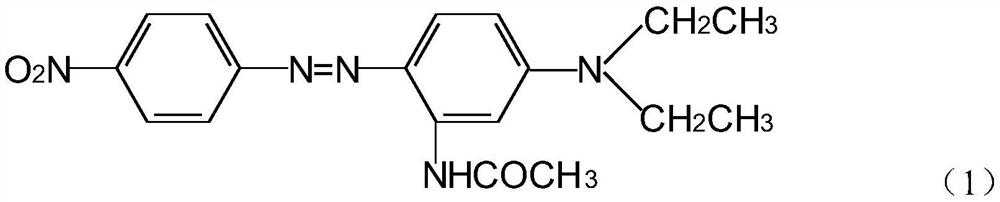

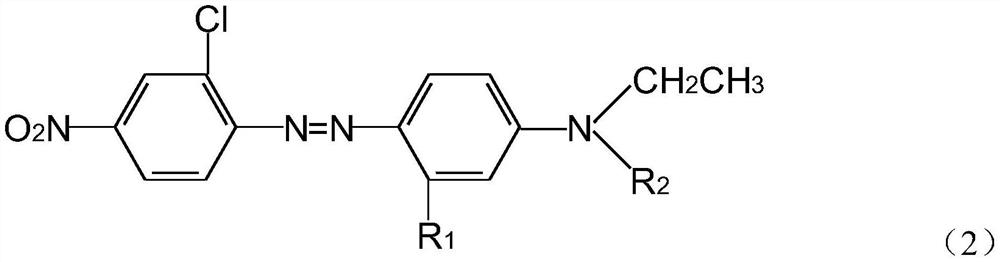

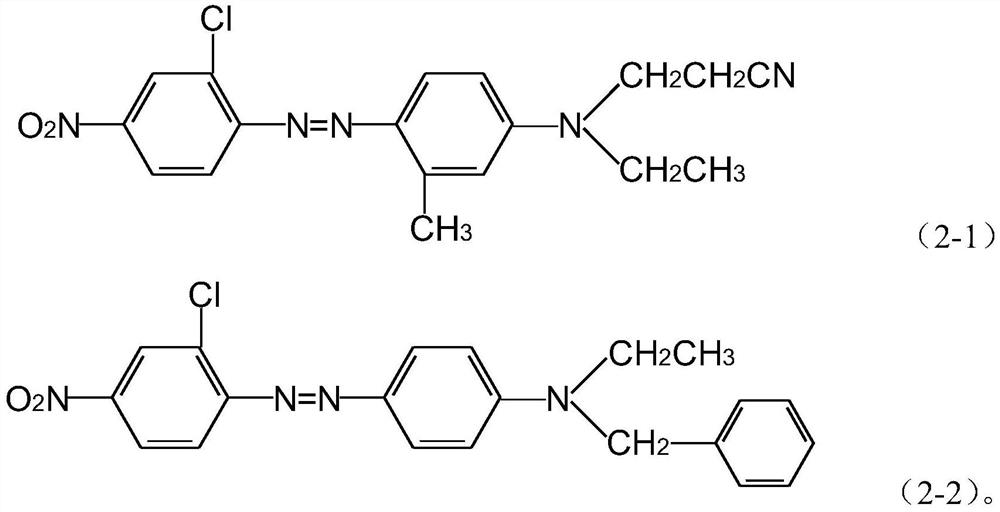

[0066] With 74 grams of component A shown in formula (1) and 26 grams of component B shown in formula (2-1), 100 grams of lignin 85A and 60 grams of dispersant MF, add 390 grams of water and stir well, grind Disperse and dry to obtain red disperse dyes.

[0067] The specific test method is as follows:

[0068] Take by weighing 2 grams of the red disperse dye of Example 1 and place in 500mL of water to make a disperse dye suspension. Take 5mL of disperse dye suspension and mix it with 95mL of water, adjust the pH of the dyeing bath to 4.5 with acetic acid as a standard sample, then mix 5mL of disperse dye suspension with 95mL of water, and adjust the pH value to 9, 10, 11 with NaOH solution And use 5mL of disperse dye suspension and 95mL of 0.4g / L NaOH solution to adjust the pH value to 12 as the test sample, and at the same time put 2g of polyester fiber into it for high temperature and high pressure dyeing, heat up to 130°C within 35 minutes, and keep it warm for 45 minutes....

Embodiment 2

[0079] Add 57 grams of formula (1) component A and 43 grams of formula (2-2) component B, 100 grams of lignin 85A and 85 grams of dispersant MF, add 428 grams of water, stir well, grind, disperse and dry to obtain red Disperse dyes.

[0080] The specific test method is as follows:

[0081] Take by weighing 2 grams of the red disperse dye of Example 2 and place in 500ml of water to make a disperse dye suspension. Take 5ml of disperse dye suspension and mix it with 95ml of water, adjust the pH of the dyeing bath to 4.5 with acetic acid as a standard sample, then mix 5ml of disperse dye suspension with 95ml of water, adjust the pH value to 9, 10, 11 with NaOH solution And use 5ml of disperse dye suspension and 95ml of 0.4g / L NaOH solution to adjust the pH value to 12 as the test sample. At the same time, put 2g of polyester fiber into it for high-temperature and high-pressure dyeing, heat up to 130°C within 35 minutes, and keep it warm for 45 minutes. Cool to 80°C for sampling....

Embodiment 3-15

[0092] Mix component A and component B additives with water according to Table 5, grind to make liquid dye or spray dry to make red disperse dye.

[0093] Table 5 Unit: Gram

[0094]

[0095] Note: The moisture content in Table 5 is the moisture content of the final dyestuff.

[0096] The red disperse dyes in Table 5 were taken by weighing 2 grams respectively and placed in 500ml of water to make a disperse dye suspension. Take 5ml of disperse dye suspension and 95ml of 0.4g / L NaOH solution to adjust the pH value to 12, and at the same time put 2g of polyester fiber into it for high temperature and high pressure dyeing, heat up to 130°C within 35 minutes, keep it warm for 45 minutes, and cool to 80°C sampling.

[0097] According to GB / T3920-2008, GB / T5718-1997, GB / T3922-2013, GB / T8427-2019 methods to measure its rubbing fastness, sublimation fastness, perspiration fastness, light fastness, the test results are shown in Table 6 Show:

[0098] Table 6: Unit: Grade

[009...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com