A kind of synthetic method of small particle size platinum-rhodium nanocrystal

A technology of nanocrystals and synthesis methods, which is applied in the field of synthesis of small-diameter platinum-rhodium nanocrystals, can solve problems such as low C-C bond cracking ability, limit the application of Pt nanocrystals, poisoning, etc., and achieve enhanced C-C bond breaking. Anti-poison ability and effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

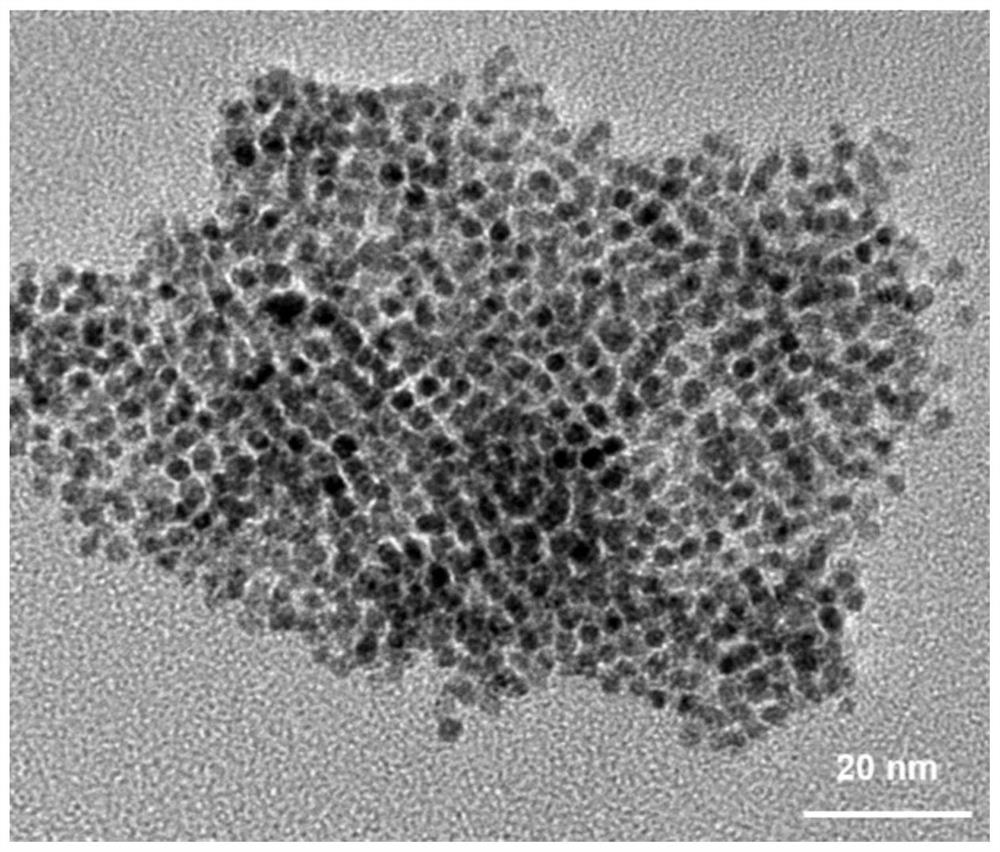

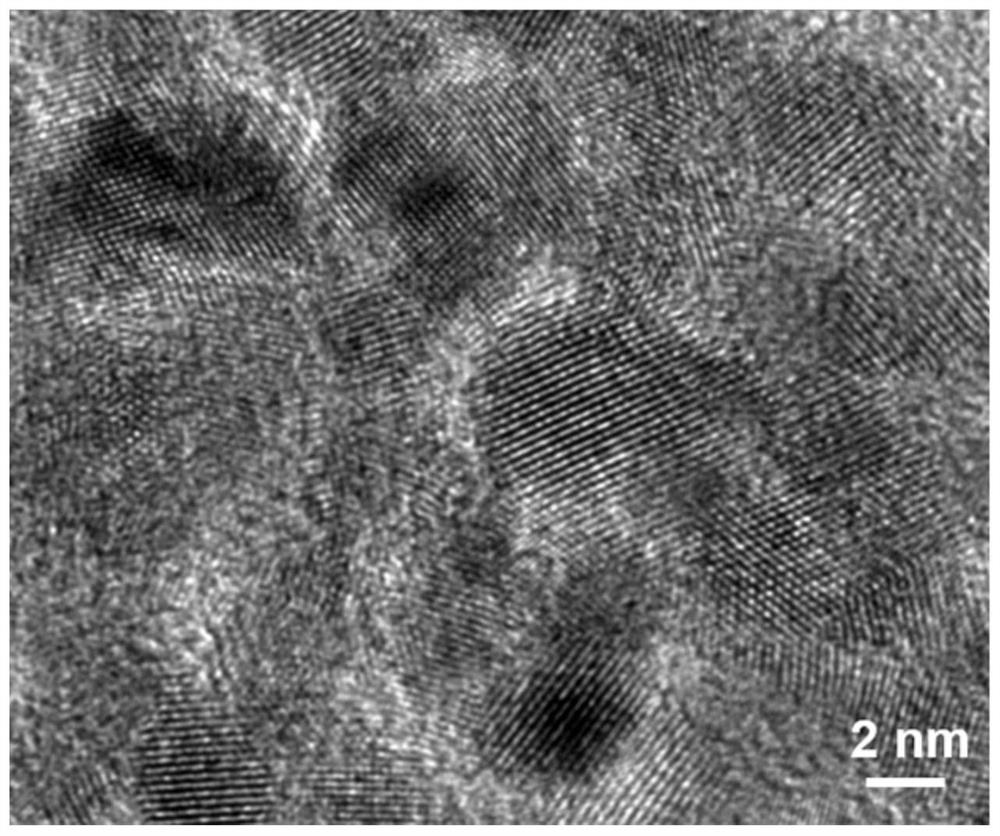

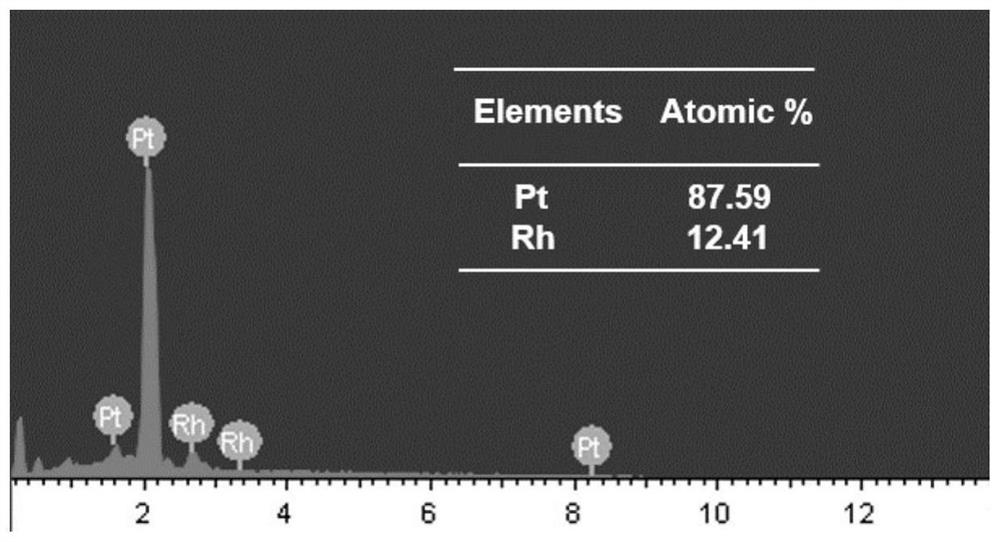

[0030] A kind of platinum-rhodium nanocrystal with small particle size, the particle size is 2-5 nanometers, and the synthesis steps are as follows:

[0031] (1) First, weigh 21 mg of potassium chloroplatinate, 25 mg of sodium hexachlororhodium (III) dodecahydrate, and 40 mg of polyvinylpyrrolidone (K30), then weigh 15 mg of tungsten hexacarbonyl, and then add them one by one to 7 ml of dimethyl Mix in the base formamide solution, and then sonicate for 20mins to obtain a mixed solution.

[0032] (2) Heat the mixed solution to 150°C at 6.5°C / min for 20mins, keep the temperature constant, and react for 8h to obtain a black solution. After the whole system is cooled, the product is centrifuged at 11000r / min for 20mins and washed repeatedly with 8ml of ethanol 3 times, and finally dispersed in 1ml ethanol for later use.

Embodiment 2

[0034] A kind of platinum-rhodium nanocrystal with small particle size, the particle size is 2-5 nanometers, and the synthesis steps are as follows:

[0035] (1) First weigh 21 mg of potassium chloroplatinate, 25 mg of sodium hexachlororhodium (III) dodecahydrate, and 160 mg of polyvinylpyrrolidone (K30), then weigh 15 mg of tungsten hexacarbonyl, and then add them one by one to 7 ml of dimethyl Mix in the base formamide solution, and then sonicate for 20mins to obtain a mixed solution.

[0036] (2) Heat the mixed solution to 150°C at 6.5°C / min for 20mins, keep the temperature constant, and react for 8h to obtain a black solution. After the whole system is cooled, the product is centrifuged at 11000r / min for 20mins and washed repeatedly with 8ml of ethanol 3 times, and finally dispersed in 1ml ethanol for later use.

Embodiment 3

[0038] A kind of platinum-rhodium nanocrystal with small particle size, the particle size is 2-5 nanometers, and the synthesis steps are as follows:

[0039] (1) First weigh 21 mg of potassium chloroplatinate, 25 mg of sodium hexachlororhodium (III) dodecahydrate, and 320 mg of polyvinylpyrrolidone (K30), then weigh 15 mg of tungsten hexacarbonyl, and then add them one by one to 7 ml of dimethyl Mix in the base formamide solution, and then sonicate for 20mins to obtain a mixed solution.

[0040] (2) Warm up the mixed solution to 150°C at 6.5°C / min for 20mins, keep the temperature constant, and the reaction time is 8h to obtain a black solution. Repeated washing 3 times, and finally dispersed in 1ml ethanol for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com