Cable tension monitoring system based on pulley shaft

A pulley shaft and cable technology, applied in the field of cable tension monitoring system, can solve the problems of poor durability, inconvenient deployment, hindering the normal retraction of cables, etc., and achieves the effects of low cost, low mass production and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

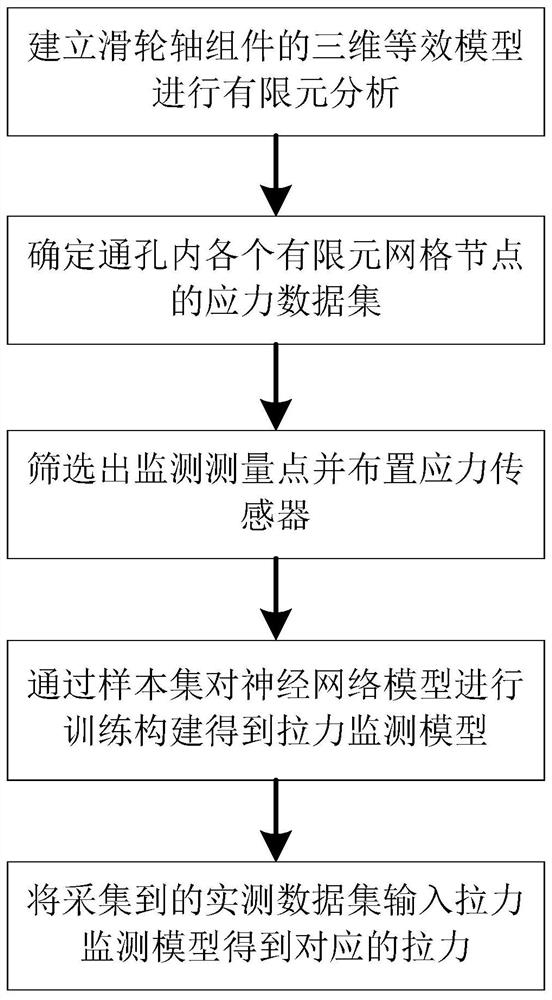

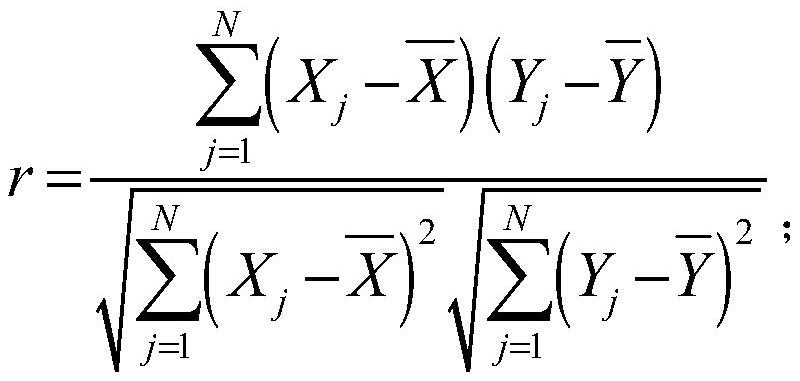

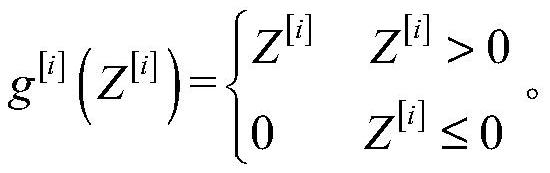

Method used

Image

Examples

Embodiment Construction

[0039] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0040] A cable tension monitoring system based on a pulley shaft includes a pulley shaft assembly and a stress sensor. The pulley shaft assembly includes a pulley shaft and a pulley installed on the pulley shaft, and the cable is wound on the pulley.

[0041] The pulley shaft is a cylindrical structure. Its size, strength and shape are designed according to industry standards. A through hole is opened at the center of the pulley shaft, and a stress sensor is installed in the through hole. The stress value is converted into According to the tension data of the cable, the diameter of the through hole is less than 1 / 4 of the diameter of the pulley shaft, and the depth of the through hole is less than 1 / 2 of the length of the pulley shaft.

[0042] At the same time, a bolt is installed on the through hole of the pulley shaft, and a threaded hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com