Small-batch permanent magnet iron removal device for laboratory

A laboratory, small batch technology, applied in magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of easy contamination, poor effect, time-consuming and labor-intensive, etc., and achieve low price and high iron removal efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in combination with specific embodiments.

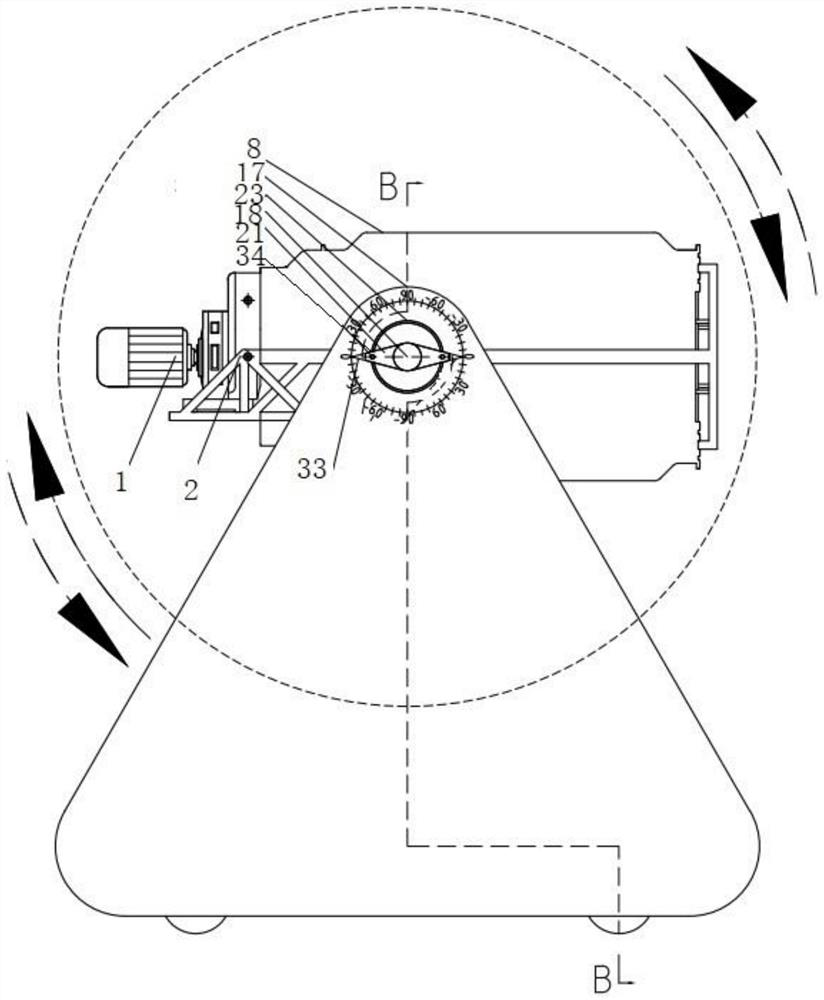

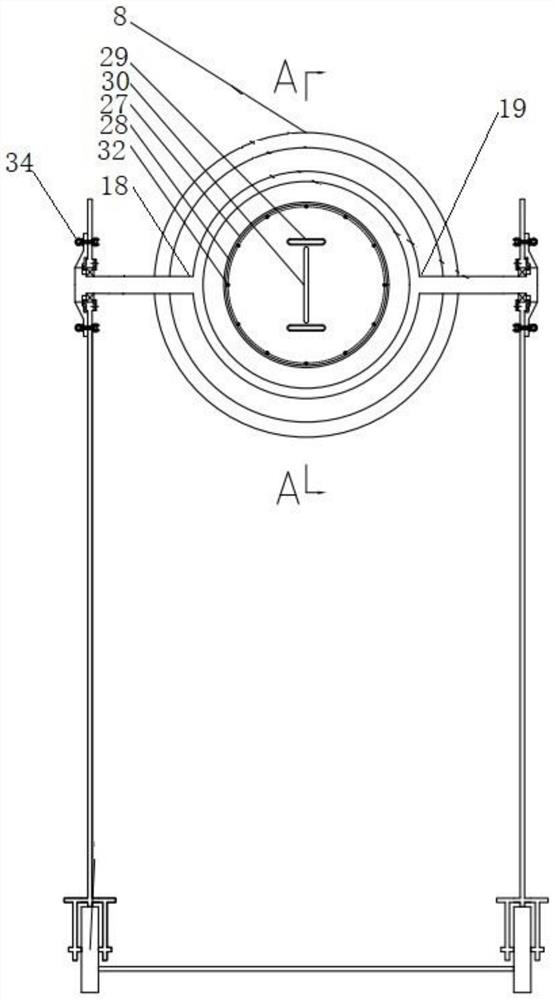

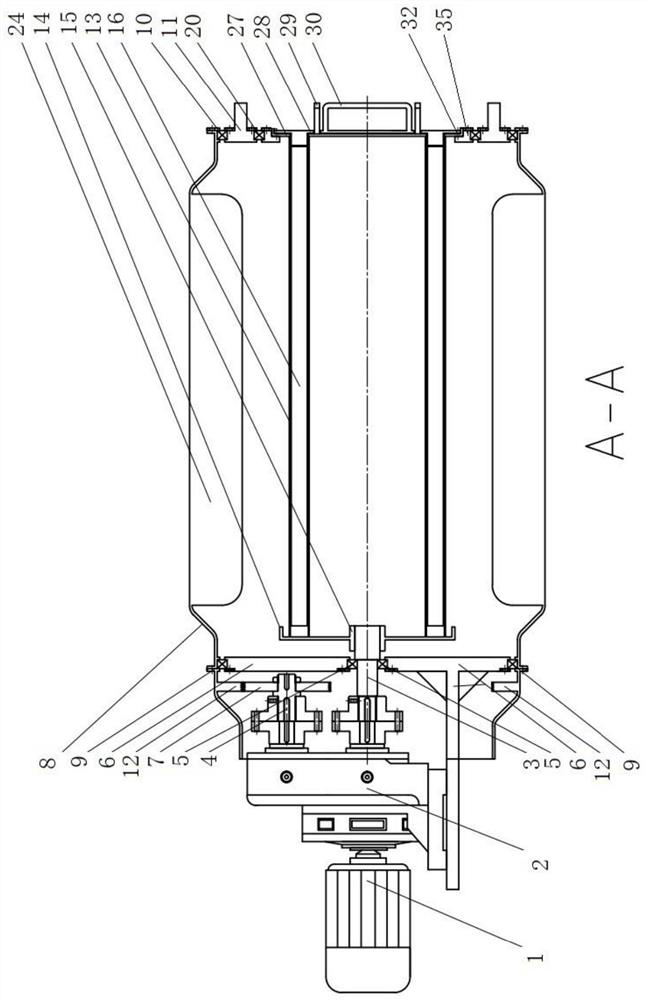

[0025] A laboratory small-batch permanent magnet iron removal device, including a motor 1 and a reducer 2 connected in sequence, the output end of the reducer 2 has two output shafts, namely the first output shaft 3 and the second output shaft 4, and the second The output rotation directions of the first output shaft 3 and the second output shaft 4 are opposite to each other, the first output shaft 3 is fixed in the first support 6 through the first bearing 5, and the output end of the first output shaft 3 has a gap with the tray 14 through the spline Fitting connection, the second output shaft 4 is connected with the first gear 7 through keyway interference fit.

[0026] The inner wall of the rotating housing 8 is provided with a lifting board 24 , the left end of the rotating housing 8 is fixed on the first support 6 through the second bearing 9 , and the right end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com