A device and method for making steel by using induction furnace and electroslag liquid casting

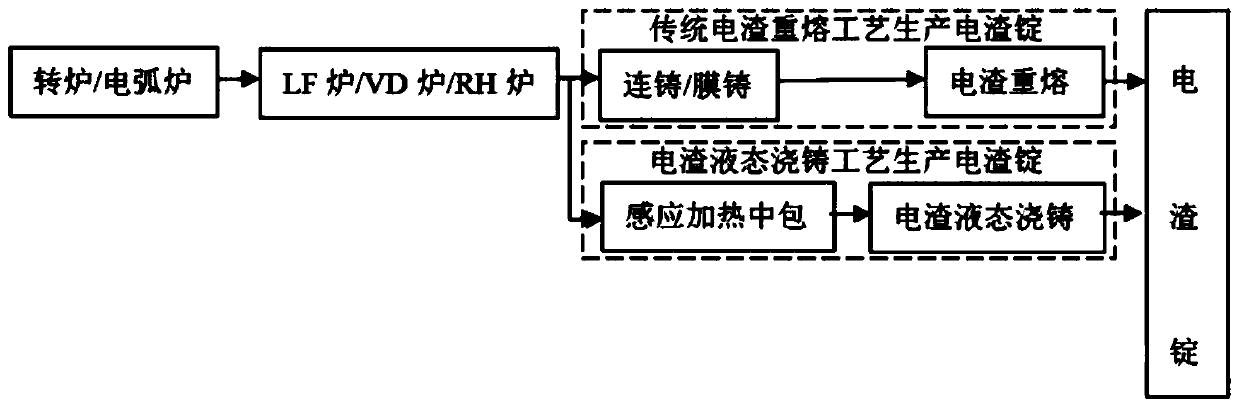

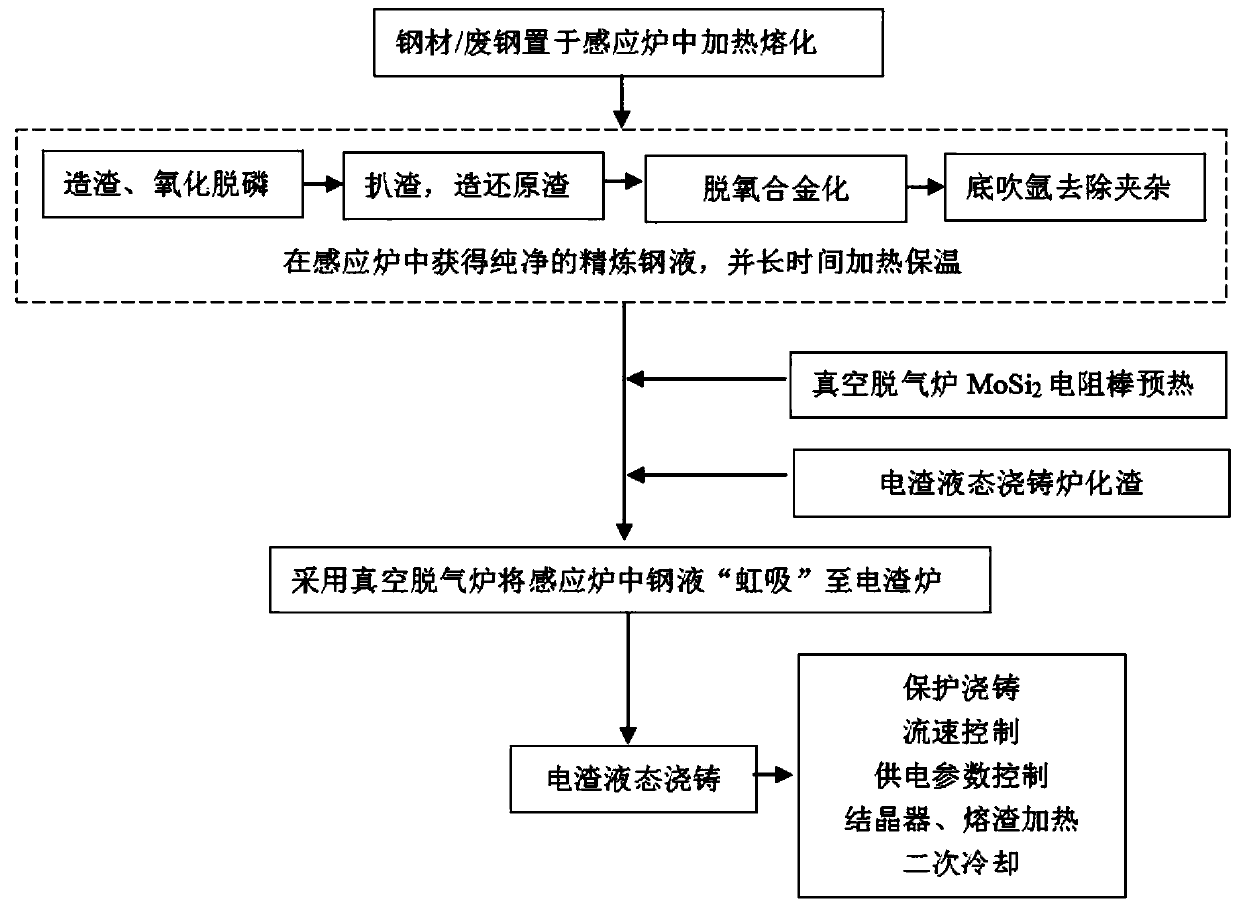

An induction furnace and electroslag technology, applied in the field of iron and steel metallurgy, can solve the problems of increasing the height of the equipment platform, increasing the content of inclusions, secondary oxidation of molten steel, etc., and achieve the effects of saving investment, short production process and small workshop space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

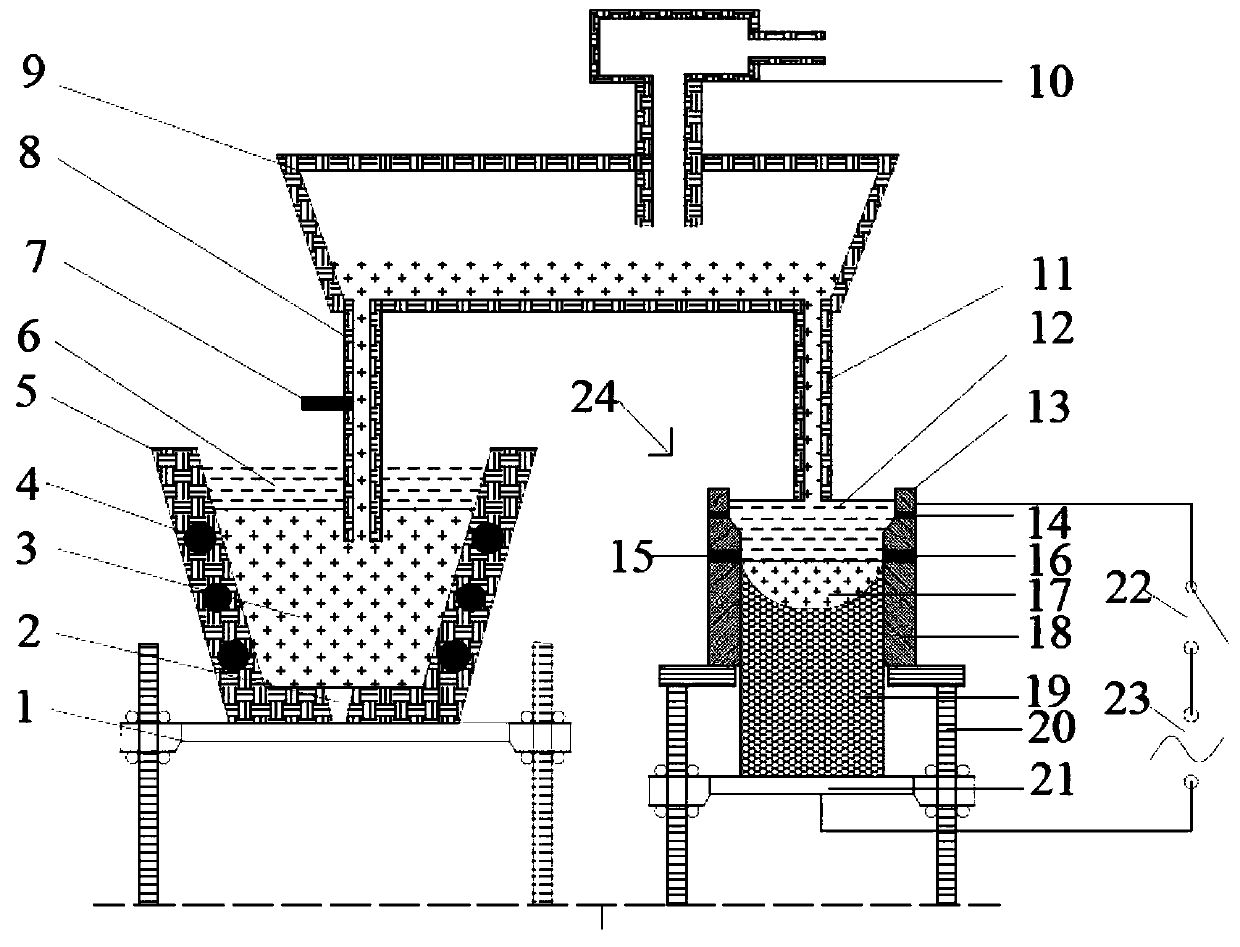

[0032] refer to figure 2 As shown, an embodiment of an induction furnace 5 and an electroslag remelting liquid casting steelmaking device of the present invention includes an induction furnace 5, a vacuum degassing furnace 9 and an electroslag liquid casting furnace 24 arranged in sequence, and the induction furnace 5 is built-in Refined molten steel 3 is provided. The induction furnace 5 is heated and kept warm through the built-in induction coil 4. The vacuum degassing furnace 9 is provided with a suction pipe 8 and a liquid delivery pipe 11. The vacuum degassing furnace 9 is evacuated by a vacuum pump 10. The suction pipe 8 is inserted in the induction furnace 5 , the liquid d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com