Efficient circular saw blade of cold saw

A technology of circular saw blades and cold saws, which is applied in the field of high-efficiency cold saw circular saw blades, and can solve problems such as substrate tearing, saw blade overheating, and saw blade vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

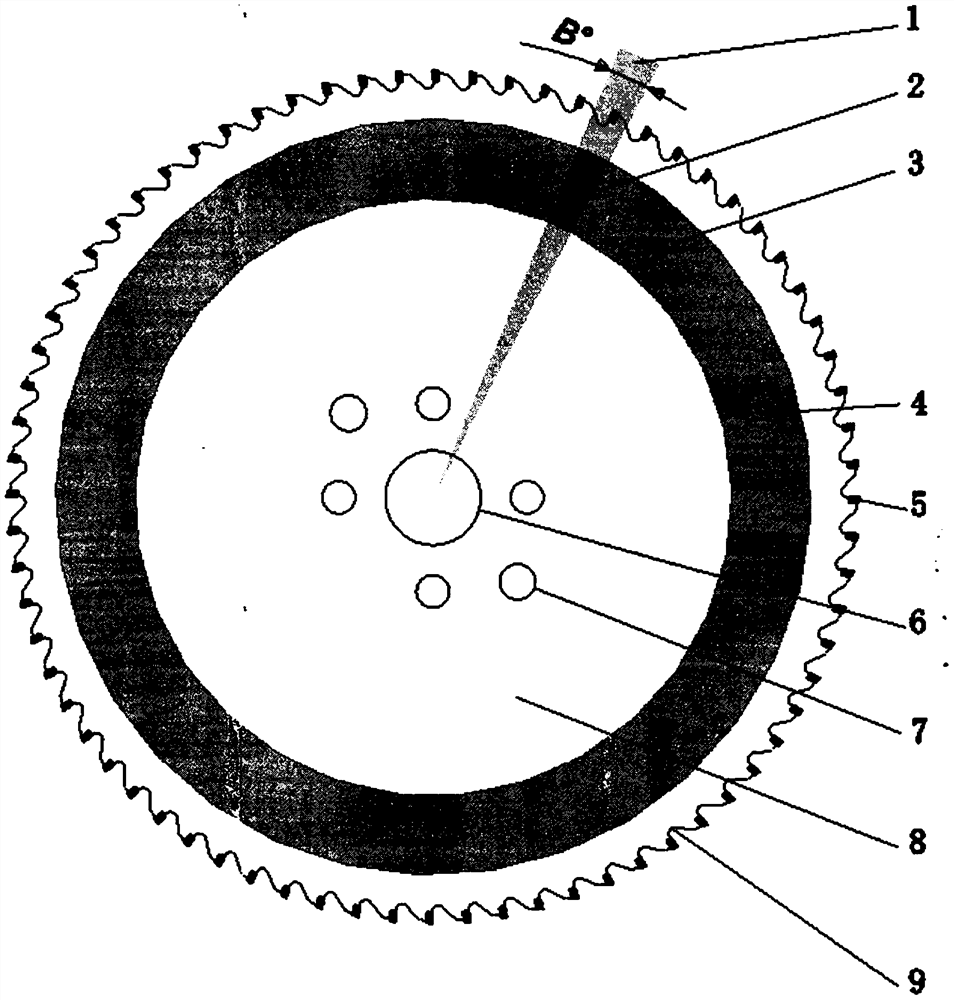

[0009] Such as figure 1 As shown, the circular saw blade 8 of the present invention is installed using the central hole 6 for centering and the mounting hole 7 to prevent slipping during work. When cutting, it passes through the silencer line at the position of the present invention, and does not affect the expansion groove when the influence of the expansion groove is removed. The saw blade cuts rigidly and breaks the vibration transmission path, eliminating vibration at the tooth end of the saw blade. Through the above arrangement, the saw blade rotates smoothly during the cutting work by using the present invention, there is no frictional noise, the wear of the saw blade is reduced, and the section of the workpiece is flat and the lines are clear. All equivalent changes or modifications completed under the technical spirit suggested by the present invention shall fall within the patent scope covered by the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com