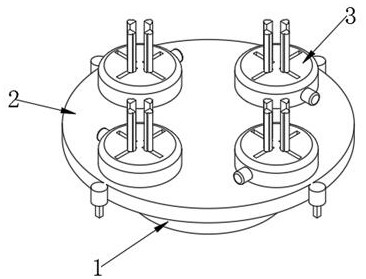

Limiting device used for thin-wall die casting

A technology for limit devices and die-casting parts, which is applied in the direction of workpiece clamping devices, electromechanical devices, electrical components, etc., which can solve the problems that are prone to errors, the inability to limit the center of thin-walled die-castings, and the surface treatment of thin-walled die-castings. problem, to achieve the effect of convenient surface treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

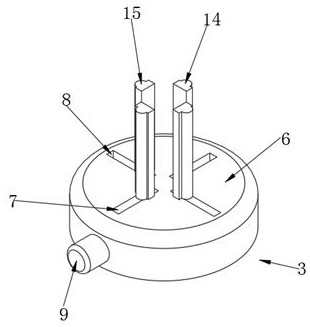

[0039] As an embodiment of the present invention, the specific operation steps of the limiting device are as follows:

[0040]Step 1: Place the thin-walled die-casting part on the limit mechanism 3. At this time, the second servo motor 9 on the fixed seat 6 works to drive the first threaded rod 10 to rotate. At this time, the rotating worm 11 cooperates with the meshing worm gear 12 for transmission. , and then drive the second threaded rod 13 to rotate. At this time, the first sliding rod 14 and the second sliding rod 15 are respectively driven to approach or move away from the first sliding groove 7 and the second sliding groove 8 until the first sliding rod 14 and the second sliding groove 8 The second sliding rods 15 are all in contact with the inner wall of the thin-walled die-casting, so as to realize the limit of the thin-walled die-casting;

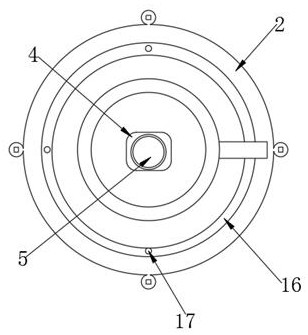

[0041] Step 2: At this time, the first servo motor 5 works, the reducer 4 adjusts the speed to drive the turntable 2 to rotate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com