On-site quality control method for sludge solidification and filler utilization, terminal and medium

A quality control method and sludge technology, applied in chemical instruments and methods, fixed/solidified sludge treatment, sludge treatment, etc., can solve the problems of large differences in sludge moisture content, substandard strength, and impractical sludge, etc. Achieve good curing effect, avoid waste, good quality control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

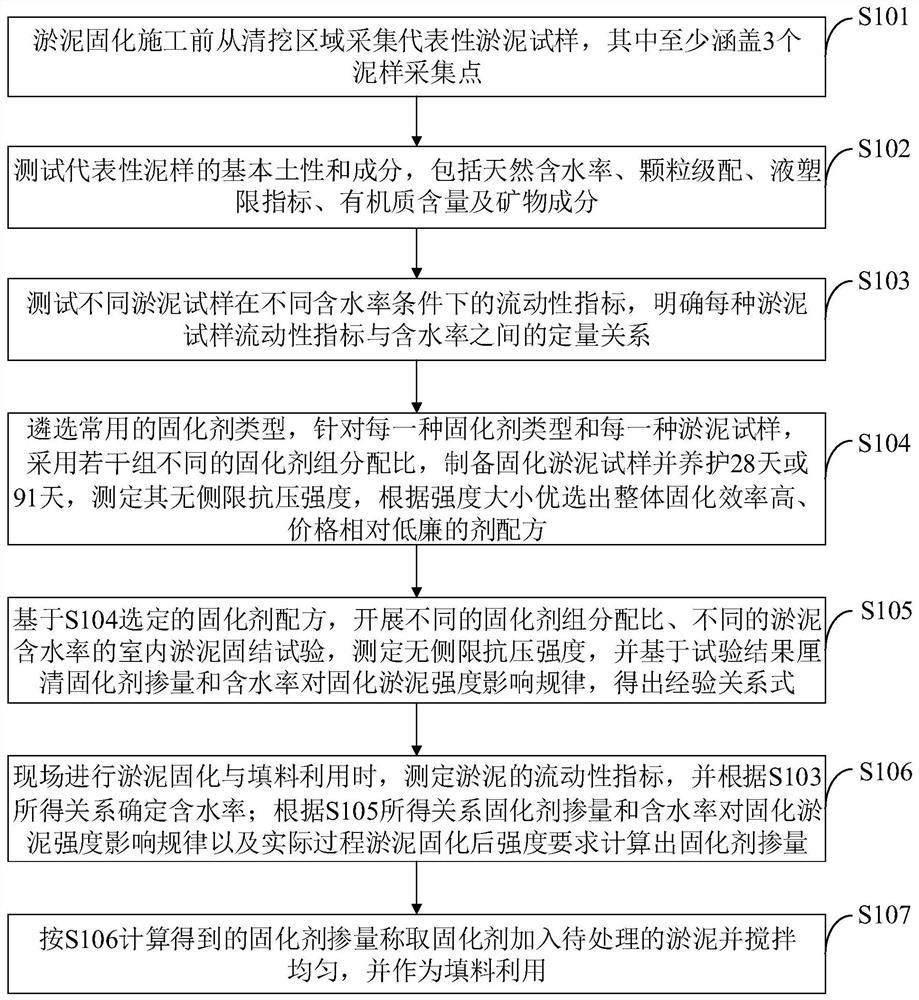

[0047] Taking the sludge generated in the construction of a certain power grid as the object, the sludge solidification treatment and filler utilization are carried out. An on-site quality control method for sludge solidification treatment and filler utilization is applied as follows:

[0048] (1) Collect representative silt samples from the excavation area before the construction of silt solidification, including at least 3 mud sample collection points;

[0049] (2) Test the basic soil and composition of representative mud samples, including natural moisture content, particle gradation, liquid-plastic limit index, organic matter content and mineral composition, etc. For the test method, see GB / T50123-2019 "Soil Engineering Standard" ;

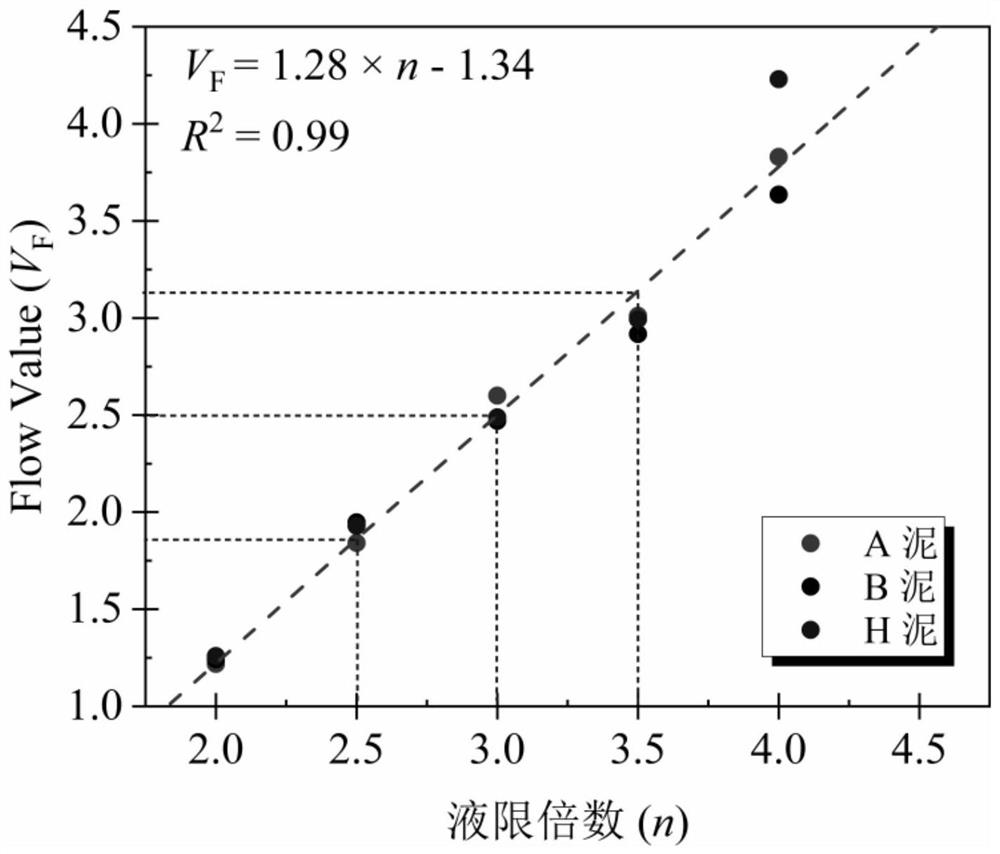

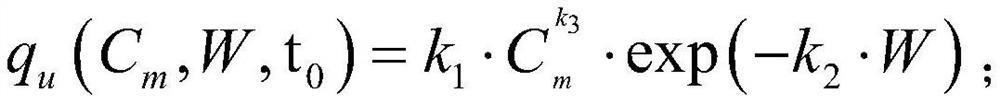

[0050] (3) Test the fluidity index (Flow Value) of different sludge samples under different water content conditions, and clarify the quantitative relationship between the fluidity index (Flow Value) of each sludge sample and the water content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com