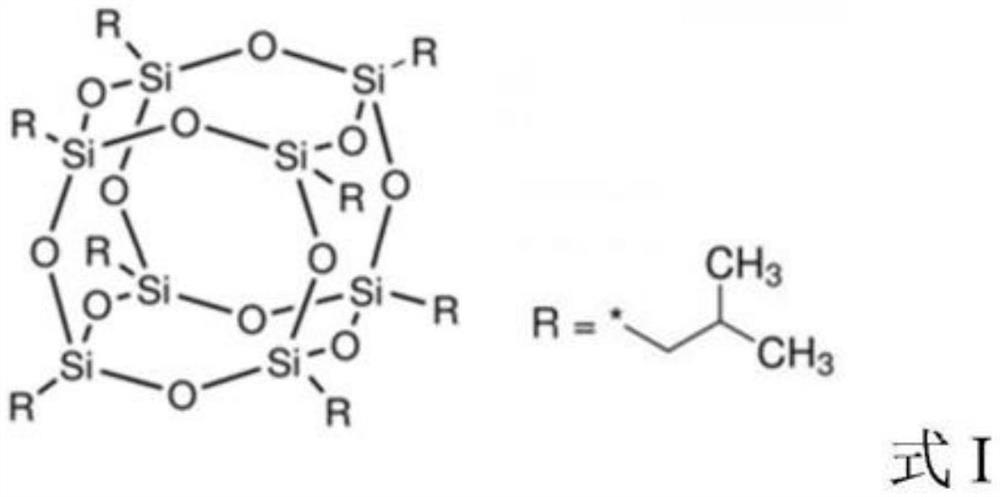

A kind of low-odor impact-resistant and scratch-resistant polypropylene composition and preparation method thereof

A polypropylene composition and scratch-resistant technology, applied in the field of plastics, can solve the problems of precipitation of additives into water, harm to health, low molecular weight, etc., and achieve the effects of reduced odor, improved scratch resistance, and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

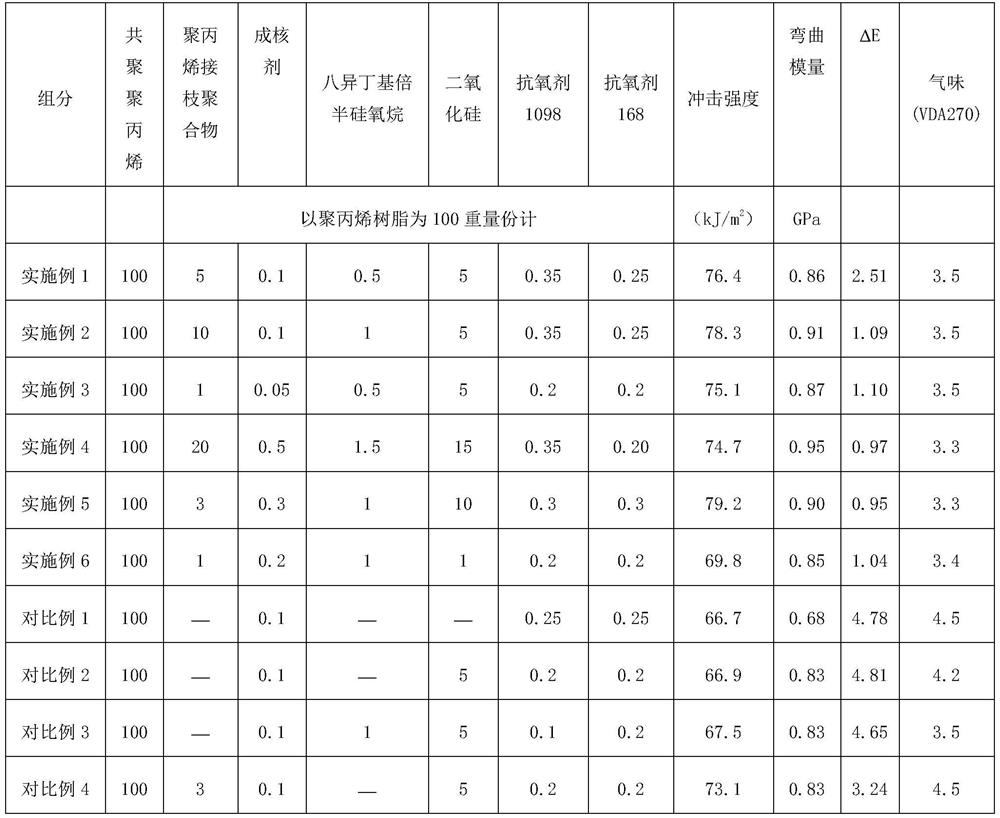

[0044] Examples 1 to 6 are used to illustrate the low-odor impact-resistant and scratch-resistant polypropylene composition and the preparation method of the present invention. Put the nucleating agent, octaisobutyl silsesquioxane, hydrophobic fumed silica and antioxidant into a high-speed mixer, and stir at 300 rpm for 2 minutes to fully mix the components Obtain the mixture; then mix the obtained mixture with the random copolymer polypropylene sample and the polypropylene graft polymer uniformly, and then pass the above mixture through a BUSS mixing unit (MKD- 30, Swiss BUSS Company), extrude and granulate under the condition of maintaining vacuum degree -0.08MPa to obtain low-odor impact-resistant scratch-resistant polypropylene resin composition. Its specific formula is shown in Table 1, wherein the content of each component is in parts by weight. The extruded pellets were dried in a constant temperature oven at 80°C for 2 hours, and then various tests were carried out. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com