Reciprocating coating equipment and coating method

A technology of coating equipment and coating cavity, which is applied in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, can solve the problems of high production cost, extremely poor economy, and many labors, and achieves an increase in the production cost. Competitive, well-structured, time-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

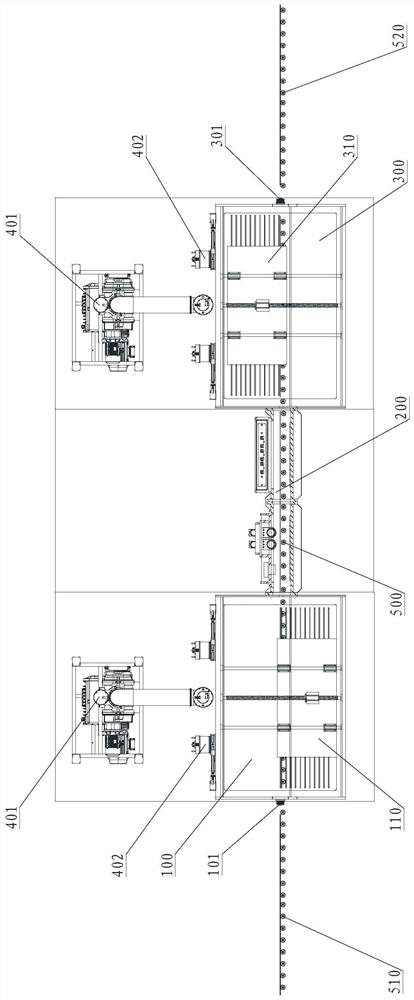

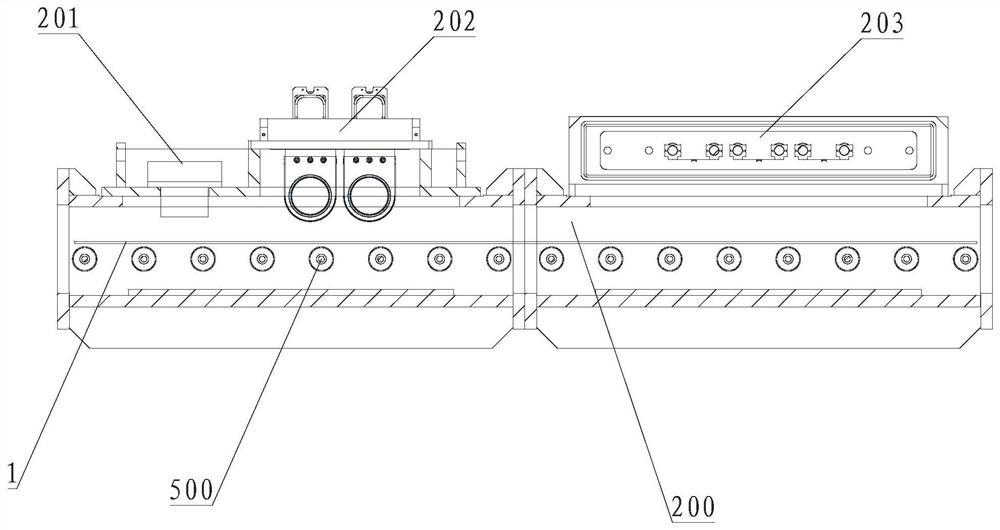

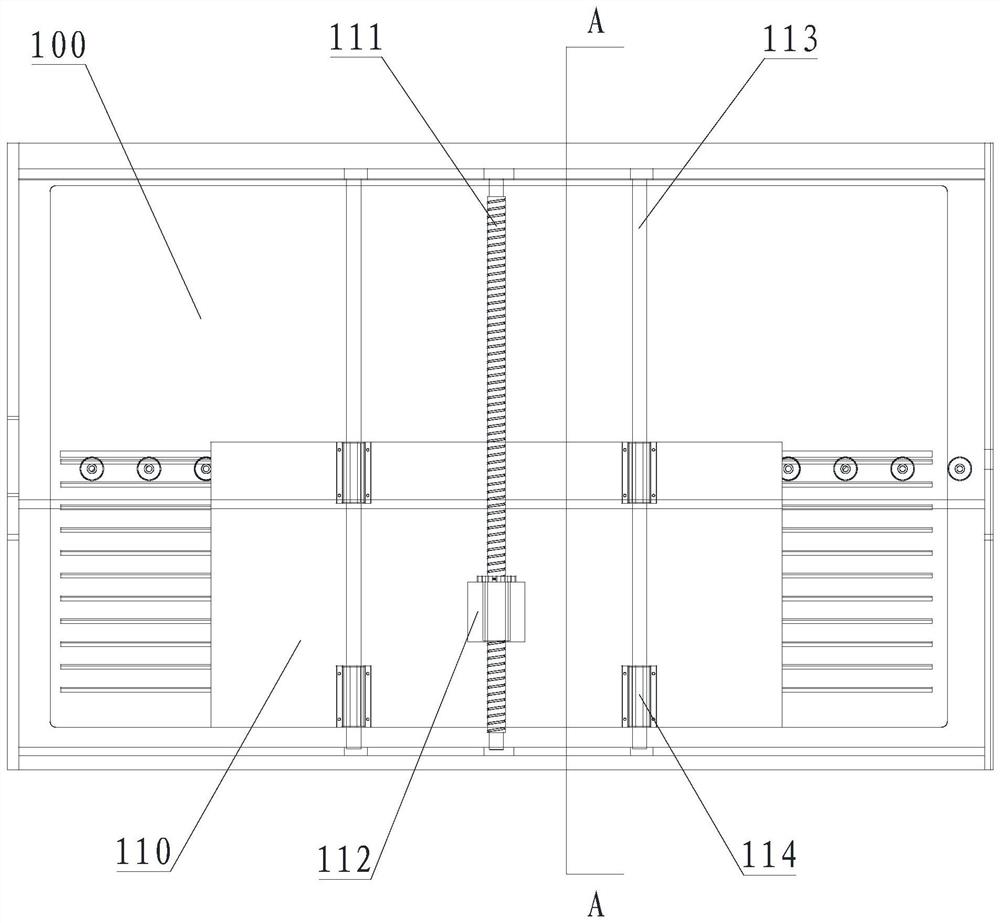

[0054] see Figure 1 to Figure 4 , a reciprocating coating device, including a first storage chamber 100, a coating chamber 200, a second storage chamber 300, a vacuum pump group and a conveying mechanism 500, the first storage chamber 100 communicates with the second storage chamber through the coating chamber 200 The cavity 300 is connected, and the transmission mechanism 500 passes through the first storage cavity 100, the coating cavity 200 and the second storage cavity 300 in sequence, and the entrance of the first storage cavity 100 is provided with a first vacuum isolation valve 101, and the The film feeding transport mechanism 510 is provided outside the film inlet of the first storage chamber 100, and the vacuum pump group is respectively connected with the first storage chamber 100 and the second storage chamber 300,

[0055] Both the first storage cavity 100 and the second storage cavity 300 are used to temporarily store the substrate 1;

[0056] The vacuum pump gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com