A kind of tough glaze sheet and its preparation process

A preparation process and tough glaze technology, which is applied in the field of tough glaze thin boards and its preparation technology, can solve the problems of increasing the load bearing of the floor, the size of the wall panels cannot be large, and the wall is difficult to fit, so as to reduce the overall cost and save production energy consumption , good decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

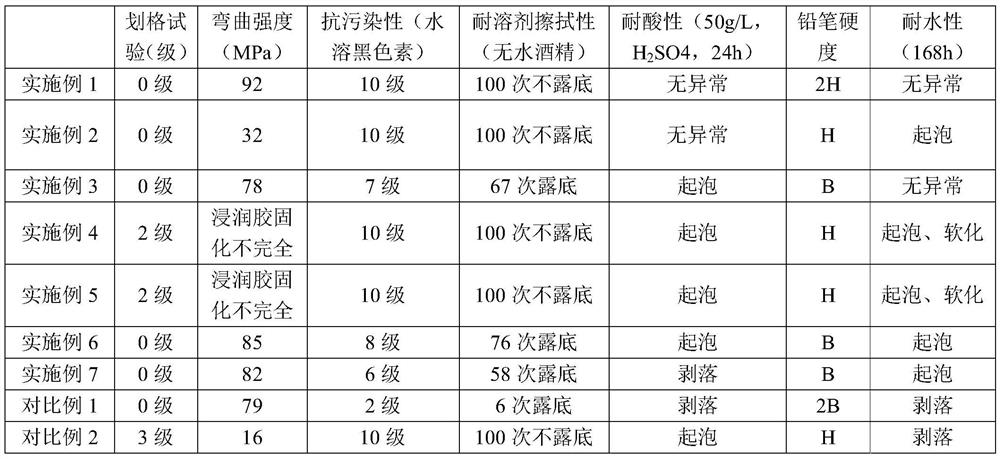

Examples

Embodiment 1

[0068] The preparation method of the tough glaze sheet of the present embodiment includes the following process steps:

[0069] 1) Wall base leveling: repair and leveling with plastering mortar or high-strength putty;

[0070] 2) Coating water-based impregnating glue: apply the stirred water-based impregnating glue on the wall with a roller, and apply an excessive amount of the dipping glue to ensure that the base layer is fully penetrated and strengthened, and the glass fiber cloth can be firmly bonded;

[0071] 3) Paste the densely woven glass fiber cloth: After the impregnating glue is applied to the wall, paste the densely woven fiberglass cloth. When pasting, pay attention to the seams, and use the scraper to repeatedly scrape the glass fiber cloth to remove air bubbles and avoid hollowing;

[0072] 4) Coating the water-based infiltration glue: apply the stirred water-based infiltration glue on the surface of the glass fiber cloth with a roller, fully impregnate the glas...

Embodiment 2

[0081] The difference between the preparation method of the tough glaze sheet of the present embodiment and the embodiment 1 is that the second application of water-based infiltration glue is omitted, and the following process steps are included:

[0082] 1) Wall base leveling: repair and leveling with plastering mortar or high-strength putty;

[0083] 2) Coating water-based impregnating glue: apply the stirred water-based impregnating glue on the wall with a roller, and apply an excessive amount of the dipping glue to ensure that the base layer is fully penetrated and strengthened, and the glass fiber cloth can be firmly bonded;

[0084] 3) Paste the densely woven glass fiber cloth: After the impregnating glue is applied to the wall, paste the densely woven fiberglass cloth. When pasting, pay attention to the seams, and use a scraper to repeatedly scrape the glass fiber cloth to remove air bubbles and avoid hollowing; usually under natural conditions above 5 °C, the drying an...

Embodiment 3

[0093] The difference between the preparation method of the tough glaze sheet of the present embodiment and the embodiment 1 is that the second application of water-based tough glaze paint is omitted, and the following process steps are included:

[0094] 1) Wall base leveling: repair and leveling with plastering mortar or high-strength putty;

[0095] 2) Coating water-based impregnating glue: apply the stirred water-based impregnating glue on the wall with a roller, and apply an excessive amount of the dipping glue to ensure that the base layer is fully penetrated and strengthened, and the glass fiber cloth can be firmly bonded;

[0096] 3) Paste the densely woven glass fiber cloth: After the impregnating glue is applied to the wall, paste the densely woven fiberglass cloth. When pasting, pay attention to the seams, and use the scraper to repeatedly scrape the glass fiber cloth to remove air bubbles and avoid hollowing;

[0097] 4) Coating the water-based infiltration glue: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com