Industrial fan

A fan and industrial technology, applied in the field of industrial fans, can solve the problems of reduced winding pressure, fan exhaust efficiency, air leakage, and fragility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

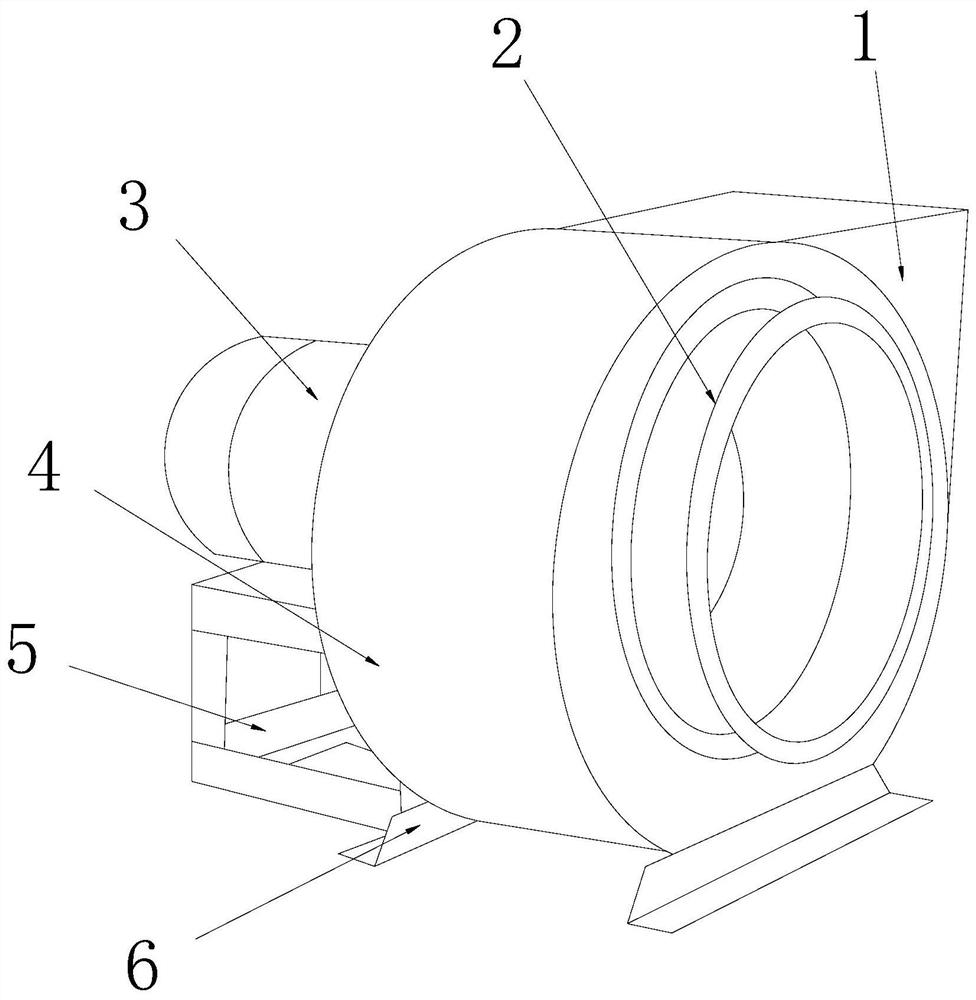

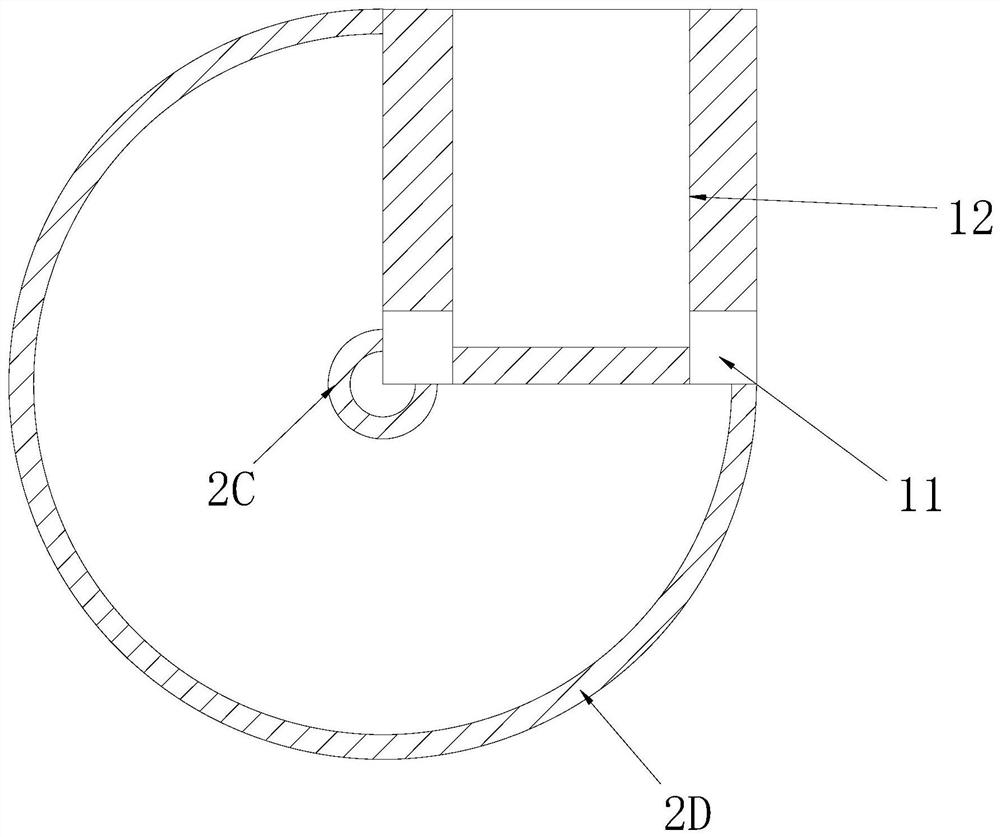

[0035] see Figure 1-Figure 8 , the present invention provides an industrial fan, the structure of which includes: an exhaust duct opening 1, a paddle rack disc groove 2, a shaft motor 3, a fan casing 4, a bracket frame 5, and a gasket 6. The paddle rack disc groove 2 and the fan casing 4 are nested together and the axes are collinear, and the exhaust duct opening 1 is inserted in the rear side of the blade rack disc slot 2 and communicates with each other. The disc groove 2 of the paddle frame is mechanically connected with the shaft motor 3 and the axis is collinear. The shaft motor 3 is installed on the top of the bracket frame 5, and the bracket frame 5 is installed on the fan casing On the left side of 4, two pads 6 are provided and are respectively attached to the left and right lower corners of the fan casing tube 4, and the paddle frame disc groove 2 is provided with a propeller frame rod 2A, a grille groove The baffle plate 2B, the collar body 2C, and the outer frame...

Embodiment 2

[0043] see Figure 1-Figure 8 , the present invention provides a kind of industrial blower fan, other respects are identical with embodiment 1, and difference is:

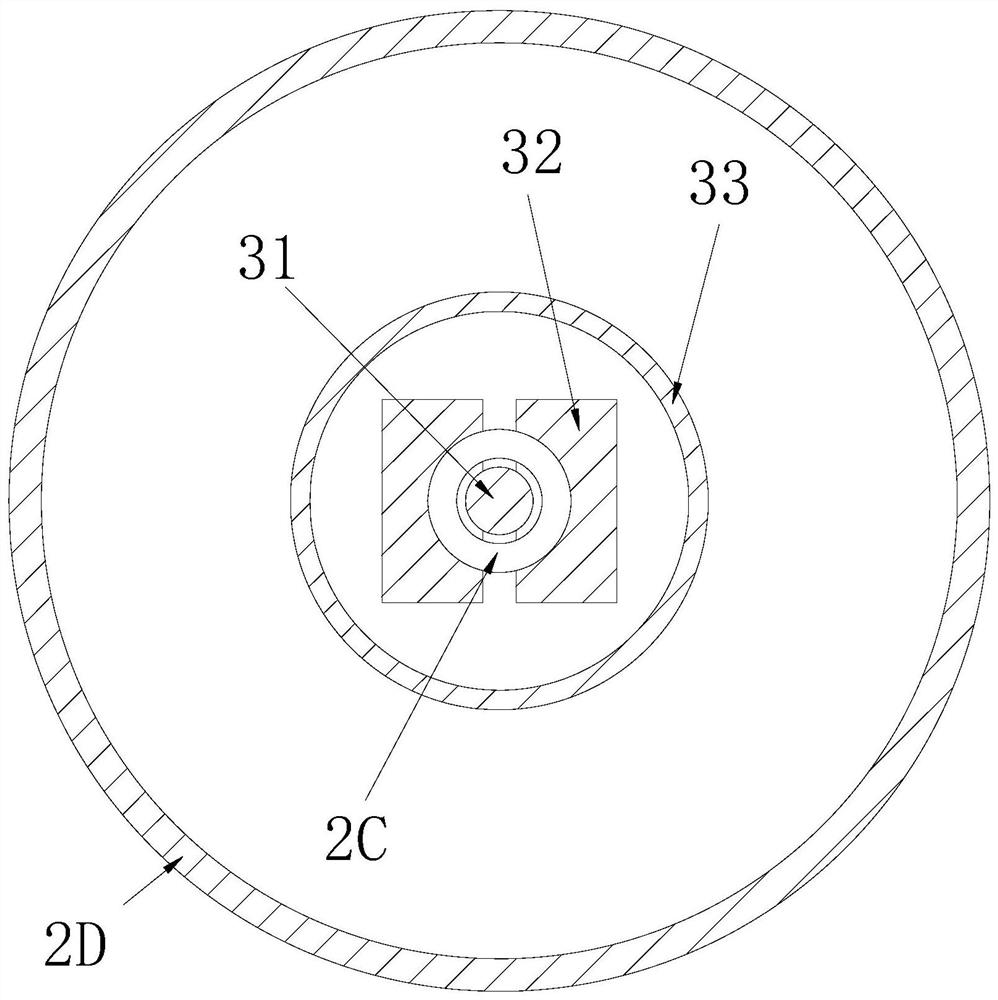

[0044] see image 3 , the shaft motor 3 is composed of a rotor shaft 31, a resistance plate 32, and a motor barrel slot 33, the rotor shaft 31 is electrically connected to the resistance plate 32, and the resistance plate 32 is installed inside the motor barrel slot 33, Through the relay rotation of the rotor shaft 31 linked with the resistance plate 32, the high efficiency of the motor operation is ensured.

[0045] see Image 6 The rotor shaft 31 is composed of a coil arc pressure plate 311, a shaft body 312, and a coil slot 313. The coil arc pressure plate 311 and the shaft body 312 adopt an interference fit, and the shaft body 312 is inserted into the inside of the coil slot 313 And the axis centers are collinear. The coil arc pressure plate 311 is a plate structure with a wide left side and a narrow right s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com