Micro-leakage detection method

A leakage detection and product technology, applied in the field of micro-leakage detection, can solve the problems of inability to determine the leakage point, large hazard impact, strict sealing requirements, etc., and achieve the effect of eliminating the risk of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013]DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS These embodiments are intended to illustrate the invention and is not limited to the present invention.

[0014]The present invention provides a micro-leak detection method, including the following steps:

[0015]S1, in the previous development, according to the experience, customer feedback and product structure, it is determined that the product may have micro-leak in the product;

[0016]S2, sprayed the region before sealing test;

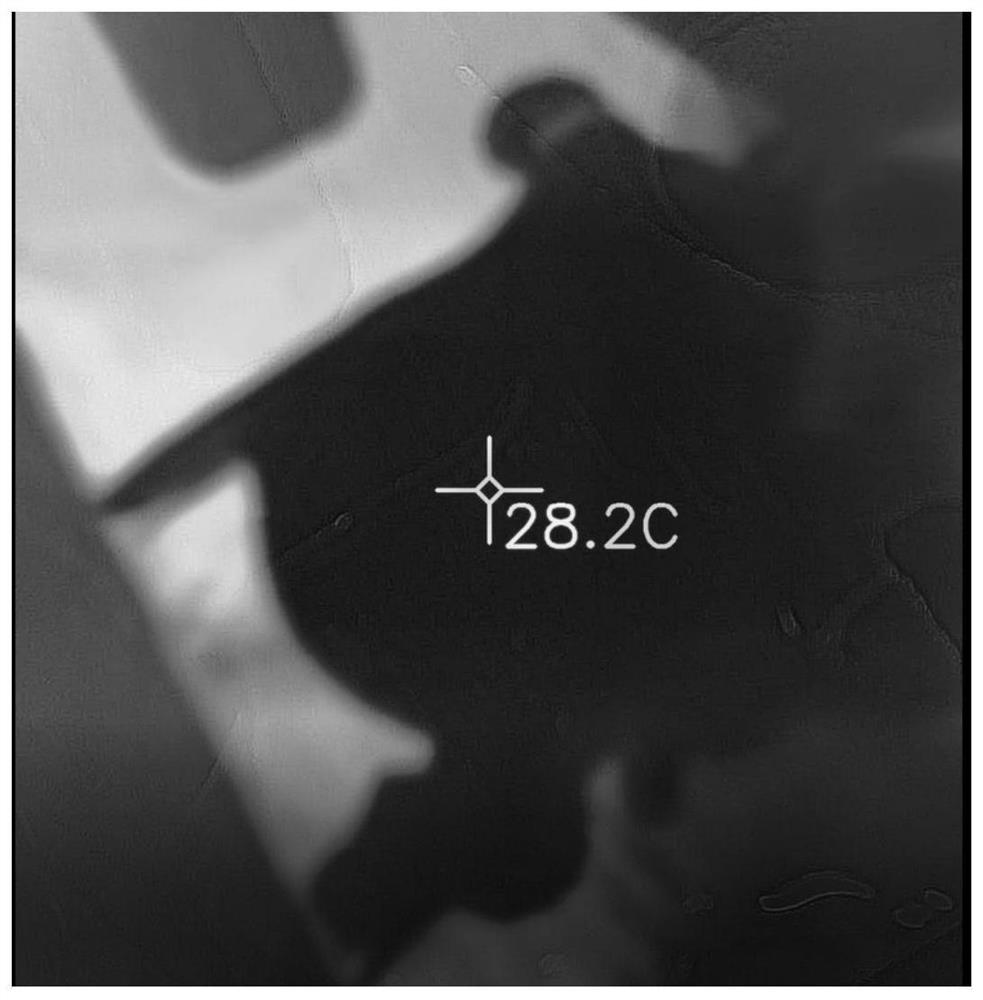

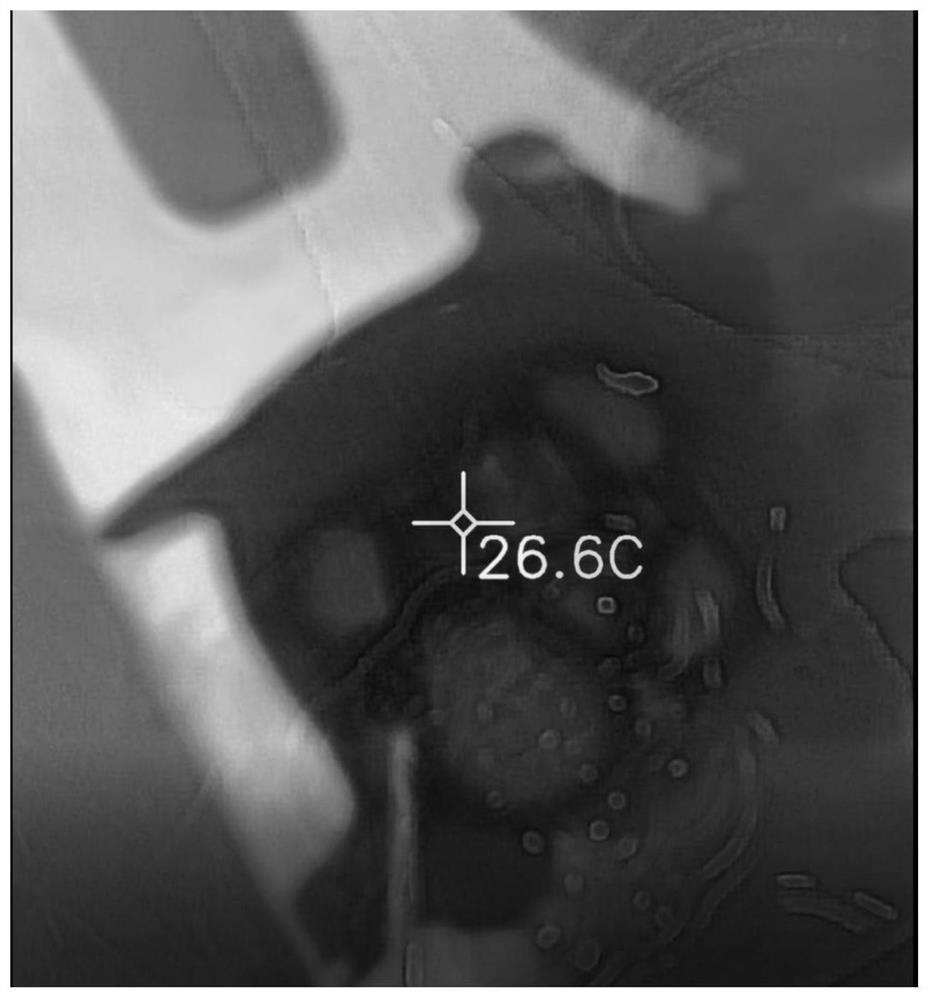

[0017]S3, when the sealing test is performed, the thermal imaging device monitors whether there is a foaming phenomenon in the spray area, if there is a foaming phenomenon, it is determined that the product is unqualified. Preferably, the thermal imaging apparatus is connected to the acquisition control system. When the foaming phenomenon occurs, the bubble heat absorption, the ambient temperature is lowered, which in turn affects thermal imaging, the acquisition control system can identify the display funct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com