Preparation method of negative electrode slurry and negative electrode slurry

A negative electrode slurry and slurry technology, which is applied in the field of electrochemistry and can solve problems such as difficulty in cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

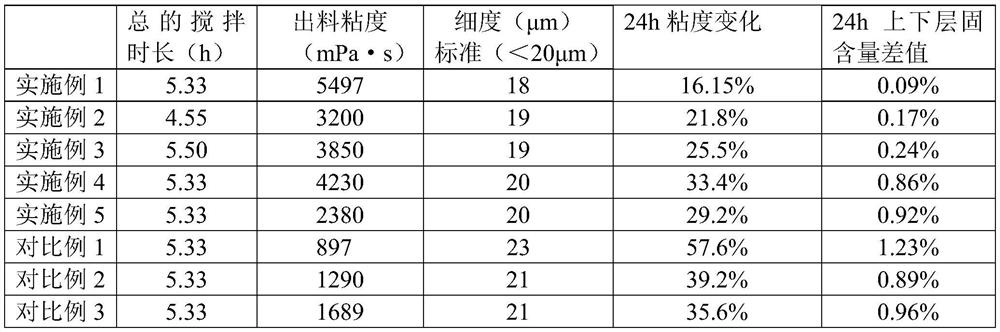

Embodiment 1

[0070] This embodiment provides a method for preparing negative electrode slurry, the method comprising the following steps:

[0071] S1: Add the negative electrode active material and conductive agent powder into the mixing equipment in proportion, and stir evenly. The stirring parameters are: revolution 20rpm, dispersion 1000rpm, stirring time 15min;

[0072] S2: Add an appropriate amount of deionized water, stir evenly, the stirring parameters are: revolution 20rpm, dispersion 650rpm, stirring time 35min, to obtain a wet slurry with a solid content of 70%;

[0073] S3: Add thickener powder accounting for 50% of the total mass of CMC powder, stir evenly, the stirring parameters are revolution 15rpm, dispersion 300rpm, stirring time 10min;

[0074] S4: Add thickener powder accounting for 20% of the total mass of CMC powder, and stir evenly. The stirring parameters are 15 rpm for revolution, 150 rpm for dispersion, and 5 min for stirring time;

[0075] S5: Add thickener powde...

Embodiment 2

[0082] S1: Add the negative electrode active material and conductive agent powder into the mixing equipment in proportion, and stir evenly. The stirring parameters are: revolution 30rpm, dispersion 1250rpm, stirring time 8min;

[0083] S2: Add an appropriate amount of deionized water, stir evenly, the stirring parameters are: revolution 25rpm, dispersion 500rpm, stirring time 40min, to obtain a wet slurry with a solid content of 65%;

[0084] S3: Add thickener powder accounting for 55% of the total mass of CMC powder, and stir evenly. The stirring parameters are revolution 25rpm, dispersion 800rpm, and stirring time 5min;

[0085] S4: Add thickener powder accounting for 20% of the total mass of CMC powder, and stir evenly. The stirring parameters are 20 rpm for revolution, 200 rpm for dispersion, and 20 min for stirring time;

[0086] S5: Add thickener powder accounting for 25% of the total mass of CMC powder, and stir evenly. The stirring parameters are revolution 20rpm, disp...

Embodiment 3

[0093] S1: Add the negative electrode active material and conductive agent powder into the mixing equipment in proportion, and stir evenly. The stirring parameters are: revolution 15rpm, dispersion 800rpm, stirring time 30min;

[0094] S2: Add an appropriate amount of deionized water, stir evenly, the stirring parameters are: revolution 20rpm, dispersion 400rpm, stirring time 60min, to obtain a wet slurry with a solid content of 60%;

[0095] S3: Add thickener powder accounting for 50% of the total mass of CMC powder, stir evenly, the stirring parameters are revolution 25rpm, dispersion 600rpm, stirring time 20min;

[0096] S4: Add thickener powder accounting for 30% of the total mass of CMC powder, and stir evenly. The stirring parameters are revolution 15rpm, dispersion 700rpm, and stirring time 10min;

[0097] S5: Add thickener powder accounting for 20% of the total mass of CMC powder, and stir evenly. The stirring parameters are revolution 25rpm, dispersion 450rpm, and sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com