A preparation method of negative electrode slurry and negative electrode slurry

A negative electrode slurry and slurry technology, which is applied in the field of electrochemistry, can solve problems such as cleaning difficulties, and achieve the effects of shortening the total time, appropriate fineness, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

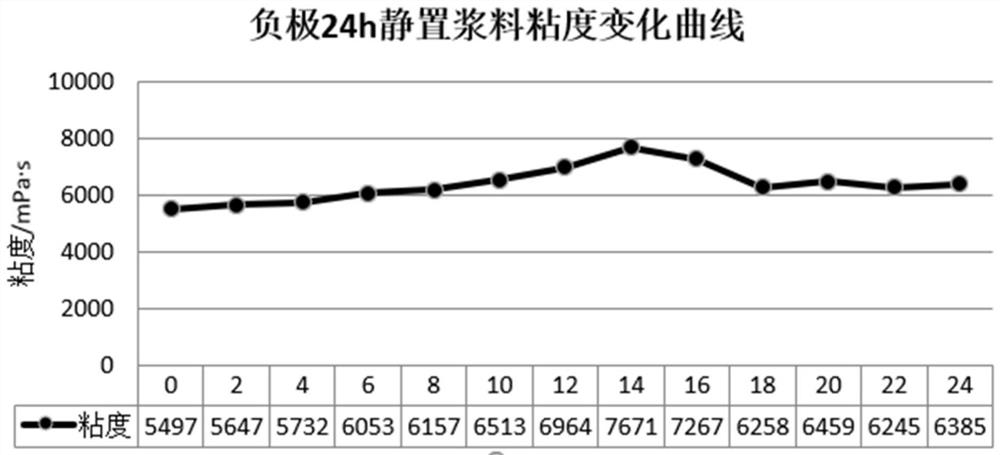

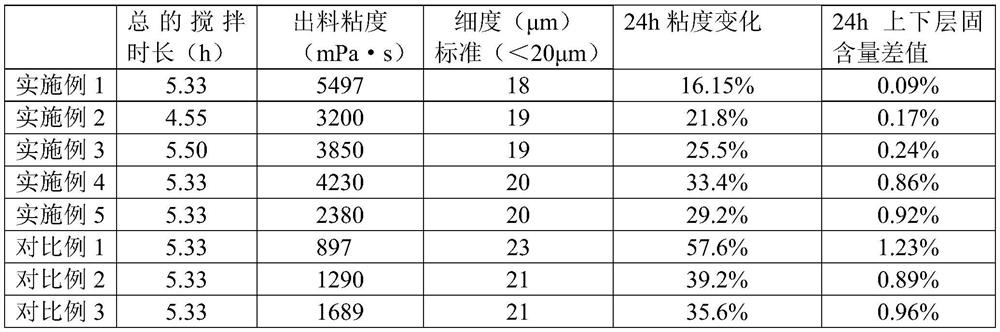

Examples

Embodiment 1

[0070] This embodiment provides a method for preparing negative electrode slurry, the method comprising the following steps:

[0071] S1: Add the negative electrode active material and conductive agent powder into the mixing equipment in proportion, and stir evenly. The stirring parameters are: revolution 20rpm, dispersion 1000rpm, stirring time 15min;

[0072] S2: Add an appropriate amount of deionized water, stir evenly, the stirring parameters are: revolution 20rpm, dispersion 650rpm, stirring time 35min, to obtain a wet slurry with a solid content of 70%;

[0073] S3: Add thickener powder accounting for 50% of the total mass of CMC powder, stir evenly, the stirring parameters are revolution 15rpm, dispersion 300rpm, stirring time 10min;

[0074] S4: Add thickener powder accounting for 20% of the total mass of CMC powder, and stir evenly. The stirring parameters are 15 rpm for revolution, 150 rpm for dispersion, and 5 min for stirring time;

[0075] S5: Add thickener powde...

Embodiment 2

[0082] S1: Add the negative electrode active material and conductive agent powder into the mixing equipment in proportion, and stir evenly. The stirring parameters are: revolution 30rpm, dispersion 1250rpm, stirring time 8min;

[0083] S2: Add an appropriate amount of deionized water, stir evenly, the stirring parameters are: revolution 25rpm, dispersion 500rpm, stirring time 40min, to obtain a wet slurry with a solid content of 65%;

[0084] S3: Add thickener powder accounting for 55% of the total mass of CMC powder, and stir evenly. The stirring parameters are revolution 25rpm, dispersion 800rpm, and stirring time 5min;

[0085] S4: Add thickener powder accounting for 20% of the total mass of CMC powder, and stir evenly. The stirring parameters are 20 rpm for revolution, 200 rpm for dispersion, and 20 min for stirring time;

[0086] S5: Add thickener powder accounting for 25% of the total mass of CMC powder, and stir evenly. The stirring parameters are revolution 20rpm, disp...

Embodiment 3

[0093] S1: Add the negative electrode active material and conductive agent powder into the mixing equipment in proportion, and stir evenly. The stirring parameters are: revolution 15rpm, dispersion 800rpm, stirring time 30min;

[0094] S2: Add an appropriate amount of deionized water, stir evenly, the stirring parameters are: revolution 20rpm, dispersion 400rpm, stirring time 60min, to obtain a wet slurry with a solid content of 60%;

[0095] S3: Add thickener powder accounting for 50% of the total mass of CMC powder, stir evenly, the stirring parameters are revolution 25rpm, dispersion 600rpm, stirring time 20min;

[0096] S4: Add thickener powder accounting for 30% of the total mass of CMC powder, and stir evenly. The stirring parameters are revolution 15rpm, dispersion 700rpm, and stirring time 10min;

[0097] S5: Add thickener powder accounting for 20% of the total mass of CMC powder, and stir evenly. The stirring parameters are revolution 25rpm, dispersion 450rpm, and sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com