Composite cigarette additive as well as preparation method and application thereof

A technology of tobacco additives and shredded tobacco, which is applied in the application and preparation of tobacco, tobacco, etc., to achieve the effect of comfortable taste, good market prospect and application value, and natural and smooth aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Take 100 grams of wood butterfly, 20 grams of distracting wood, and 10 grams of emblica, a total of 130 grams. After mixing evenly, crush through a 200-mesh sieve, add 1040 grams of 50% (concentration) ethanol, put it in an ultrasonic cleaner, set Ultrasonic power 400W, extract at 40°C for 30 minutes, filter through gauze, pass through a ceramic membrane with a pore size of 100nm, pass the permeated membrane solution through a PVDF roll-type membrane with a molecular weight cut-off of 10KDa, and then filter the obtained filtrate A PVDF coiled membrane with a relative molecular mass of 5KDa was cut off to obtain membrane separation permeate, which was concentrated under reduced pressure in a water bath at 40°C to a semi-fluid state to obtain 14.5 grams of composite cigarette additive.

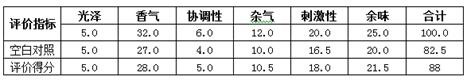

[0016] Dissolve the obtained composite tobacco additive at 0.01% of the weight of shredded tobacco in distilled water to form a saturated solution, spray it on the finished shredded tobacc...

Embodiment 2

[0020] Take 120 grams of wood butterfly, 40 grams of distracting wood, 16 grams of emblica, a total of 176 grams, mix well, crush through a 200-mesh sieve, add 1760 grams of 60% (concentration) ethanol, put it in an ultrasonic cleaner, set Ultrasonic power 600W, extract at 45°C for 40 minutes, filter through gauze, pass through a ceramic membrane with a pore size of 100nm, pass the permeated membrane solution through a PVDF roll-type membrane with a molecular weight cut-off of 10KDa, and then filter the obtained filtrate A PVDF roll-type membrane with a relative molecular mass of 5KDa was cut off to obtain membrane separation permeate, which was concentrated under reduced pressure in a water bath at 50°C to a semi-fluid state to obtain 20.6 grams of composite cigarette additive.

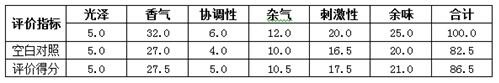

[0021] Dissolve the obtained composite tobacco additive at 0.05% of the weight of shredded tobacco in 50% (concentration) ethanol to form a saturated solution, spray it on the finished shredded tobacc...

Embodiment 3

[0025] Take 160 grams of wood butterfly, 60 grams of distracting wood, 20 grams of emblica, a total of 240 grams, after mixing evenly, crush through a 200-mesh sieve, add 2880 grams of 65% (concentration) ethanol, put it in an ultrasonic cleaner, set Ultrasonic power 800W, extract at 50°C for 50 minutes, filter through gauze, pass through a ceramic membrane with a pore size of 100nm, pass the permeated membrane solution through a PVDF roll-type membrane with a molecular weight cut-off of 10KDa, and then filter the obtained filtrate A PVDF roll-type membrane with a relative molecular weight cut-off of 5KDa was used to obtain membrane separation permeate, which was concentrated under reduced pressure in a water bath at 55°C to a semi-fluid state to obtain 28.2 grams of composite cigarette additive.

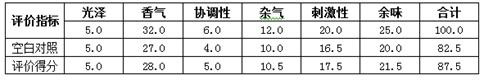

[0026] Dissolve the obtained composite tobacco additive in 0.1% of the weight of shredded tobacco in 50% (concentration) propylene glycol solution to form a saturated solution, spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com