Disinfection facility and method for refrigerated container transportation system

A technology for refrigerated containers and transportation systems, which is applied in sanitary equipment, disinfection, and applications for toilets. It can solve problems such as the impact of parts such as engines and tires, and achieve the effects of increasing vibration, maintaining freshness, and facilitating disinfection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

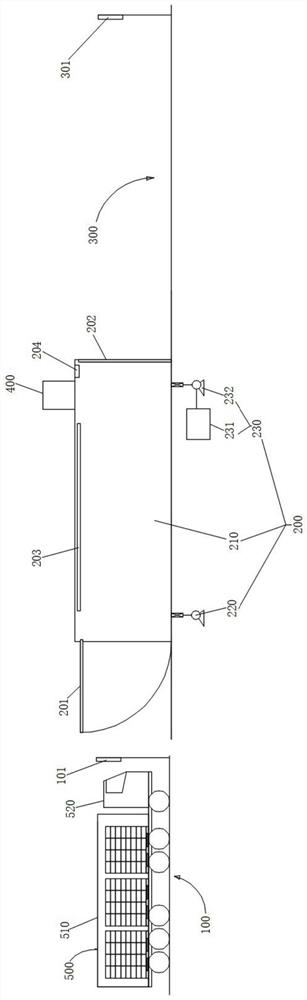

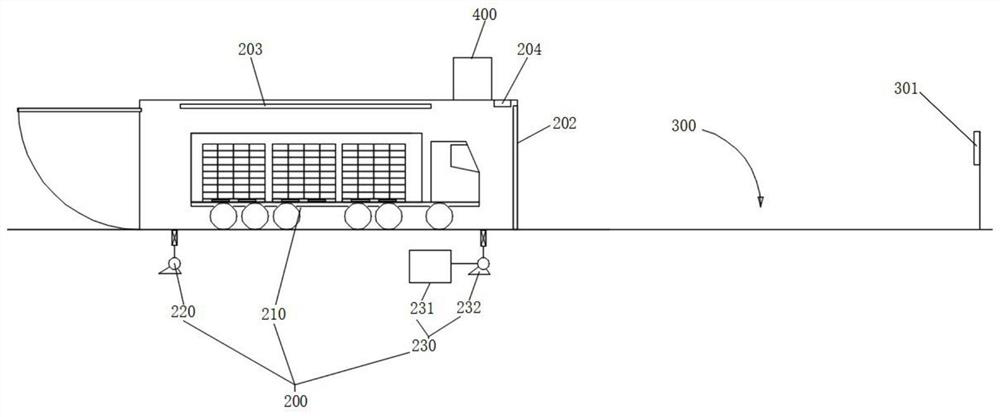

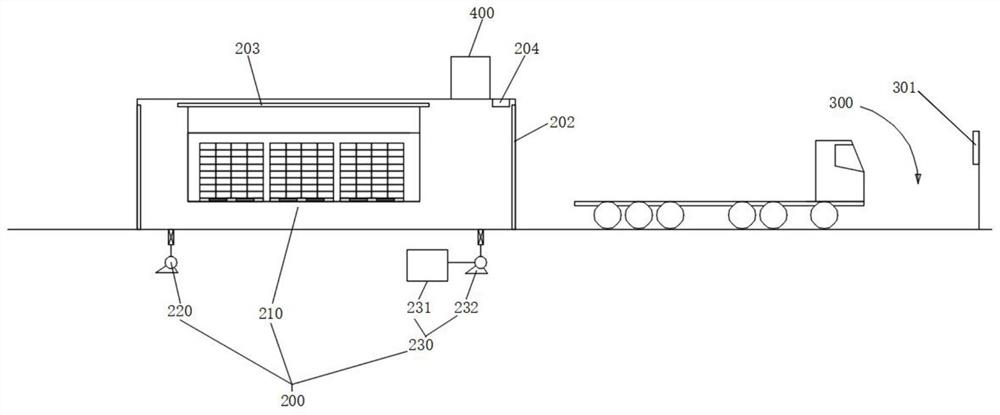

[0061] see Figure 1-Figure 4 As shown, a disinfection facility for a refrigerated container transport system, comprising:

[0062] Waiting area 100 to be processed, disinfection system 200, processing waiting area 300 and central control system 400;

[0063] The waiting area 100 to be processed, the disinfection system 200, and the waiting area 300 for processing are arranged in sequence from left to right;

[0064] The waiting area 100 to be processed is provided with a first prompter 101; the waiting area 100 to be processed is a waiting area for the refrigerated container transport vehicle 500 to be disinfected; the refrigerated container transport system 500 is composed of a refrigerated container 510 and a transport vehicle 520 composition;

[0065] The disinfection system 200 includes a disinfection chamber 210, a vacuum pumping device 220, and an ozone supply device 230; the disinfection chamber 210 is a working area for sterilizing the refrigerated container 510, an...

Embodiment 2

[0076] A disinfection method for a disinfection facility of a refrigerated container transportation system, comprising the steps of:

[0077] S1. Refrigerated container transport vehicles are waiting in the waiting area for processing, see figure 1 shown;

[0078] S2. The central control system sends an instruction to the first prompter to prompt the refrigerated container transport vehicle to enter the disinfection warehouse;

[0079] S3. The refrigerated container transport vehicle enters the disinfection warehouse through the entrance of the disinfection warehouse and stops stably, see figure 2 shown;

[0080] S4. The central control system controls the operation of the detacher, so that the refrigerated container is raised and detached from the transport vehicle;

[0081] S5. The central control system controls the second prompter to issue an instruction to prompt the transport vehicle to leave the disinfection chamber;

[0082] S6. Open the door of the refrigerated c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com