Probe side hole processing machine

A processing machine and probe technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to use automatic equipment for mass production, small products, etc. The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention will be further described in detail below in conjunction with the description of the drawings and specific embodiments.

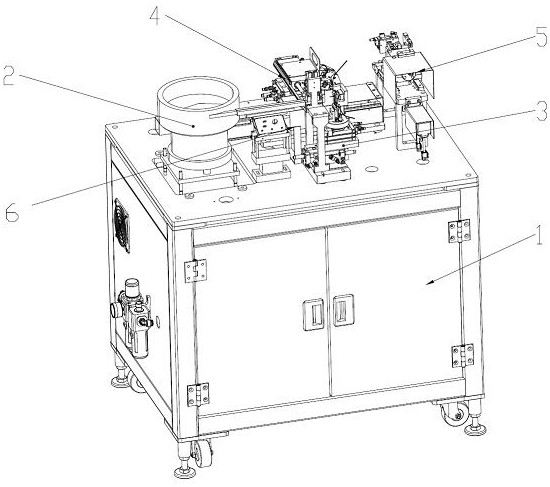

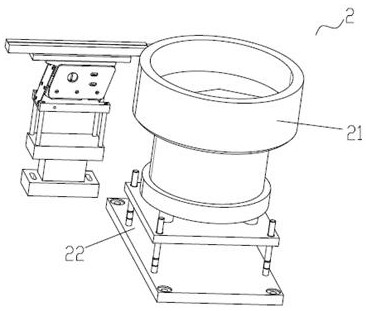

[0033] see figure 1 , the embodiment of the present invention provides a probe side hole processing machine, including: a vibrating plate feeding mechanism 2 for conveying probes, a retrieving mechanism 3 for obtaining probes in the vibrating plate feeding mechanism 2, and a material retrieving mechanism The probe in the mechanism 3 is transported to the carrying mechanism 4 of the servo milling mechanism 5, the servo milling mechanism 5 connected with the carrying mechanism 4, the servo milling mechanism 5 clamps a probe and mills the side of the probe; The material mechanism 3 is connected with the vibrating plate feeding mechanism 2 , the conveying mechanism 4 is connected with the reclaiming mechanism 3 , and the conveying mechanism 4 is also connected with the servo milling mechanism 5 .

[0034] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com