Detonator packaging assembly

A detonator and assembly technology, applied in the field of packaging equipment for civil explosives, can solve the problems of occupation, waste of production resources, transportation/storage resources, long space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

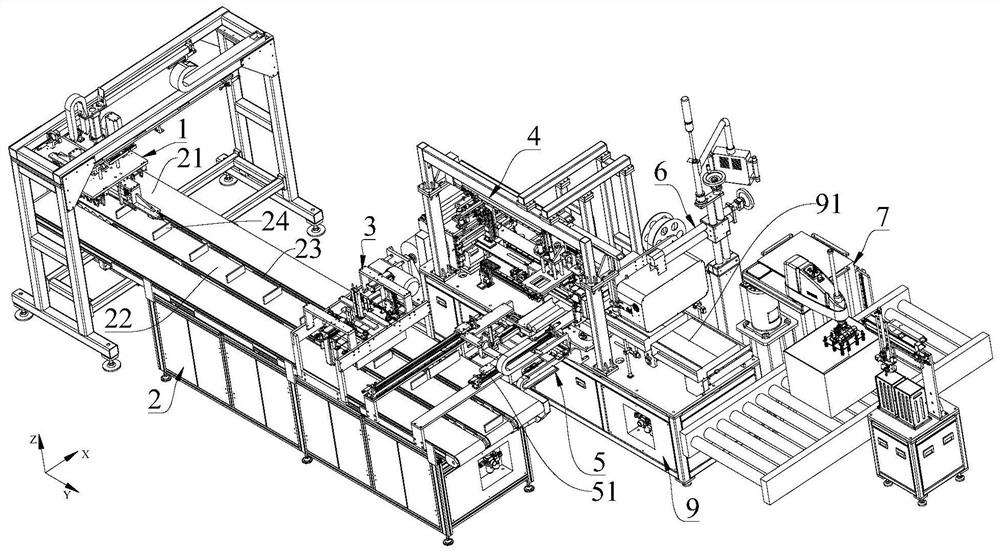

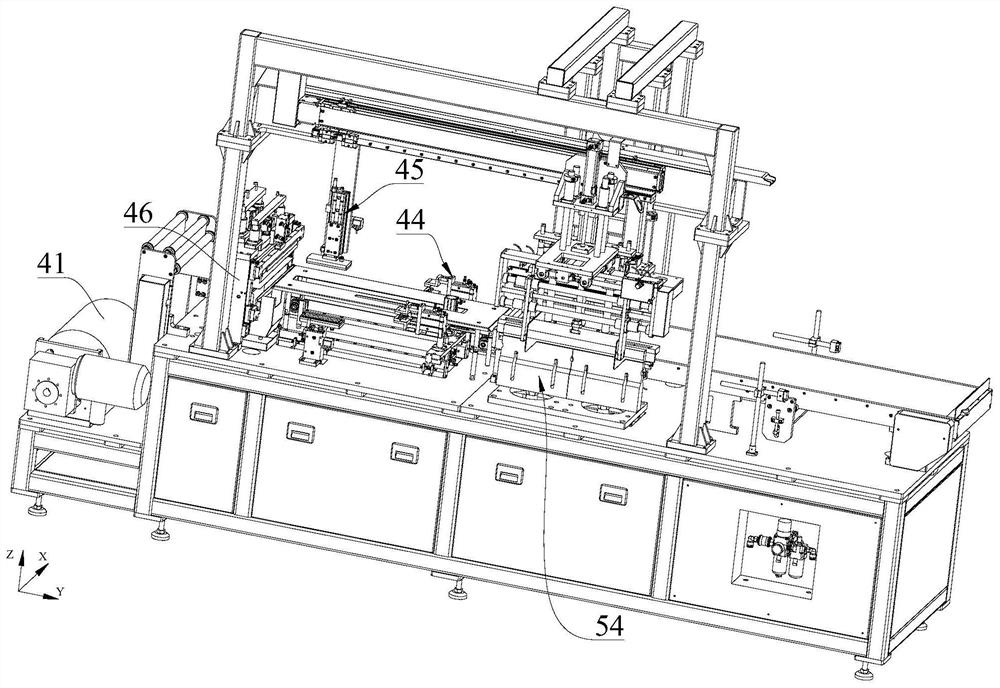

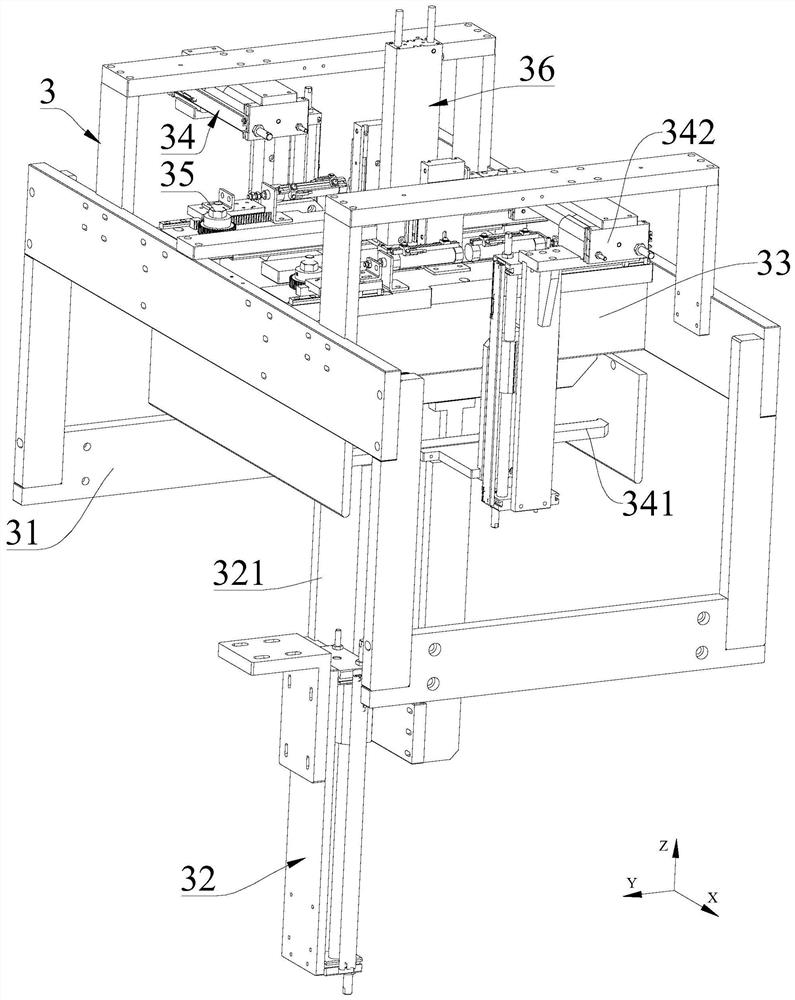

[0053] Please refer to Figure 1 to Figure 14 , Embodiment 1 of the present invention is as follows: figure 1 , figure 2 with Figure 4 As shown, the detonator packaging assembly can be used for packaging electronic detonators, etc., which includes a feeding device 1, a conveying line 2, a detonator folding line device 3, a detonator bag opening device 4, a detonator bag vacuum sealing device 5, and a labeling device. device 6 and boxing device 7; the feeding device 1 is used to place the wire handle 8 on the conveying line 2, the conveying line 2 is used to convey the wire handle 8, and the detonator folding line device 3 is used for bending The thread end of the folding wire handle 8, the detonator bag opening device 4 is used to make a packaging bag and stretch the packaging bag, and the detonator bag vacuum sealing device 5 is used to bend the thread end 8 Put it into the opened packaging bag and vacuumize and seal the packaging bag. The labeling device 6 is used to la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com