Automatic paper tube erecting device

A technology for erecting devices and paper tubes, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of low work efficiency and high labor intensity, so as to reduce labor intensity, improve work efficiency, enhance strength and The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with specific examples. However, the uses and purposes of these exemplary embodiments are only used to illustrate the present invention, and do not constitute any form of limitation to the actual protection scope of the present invention, nor limit the protection scope of the present invention thereto.

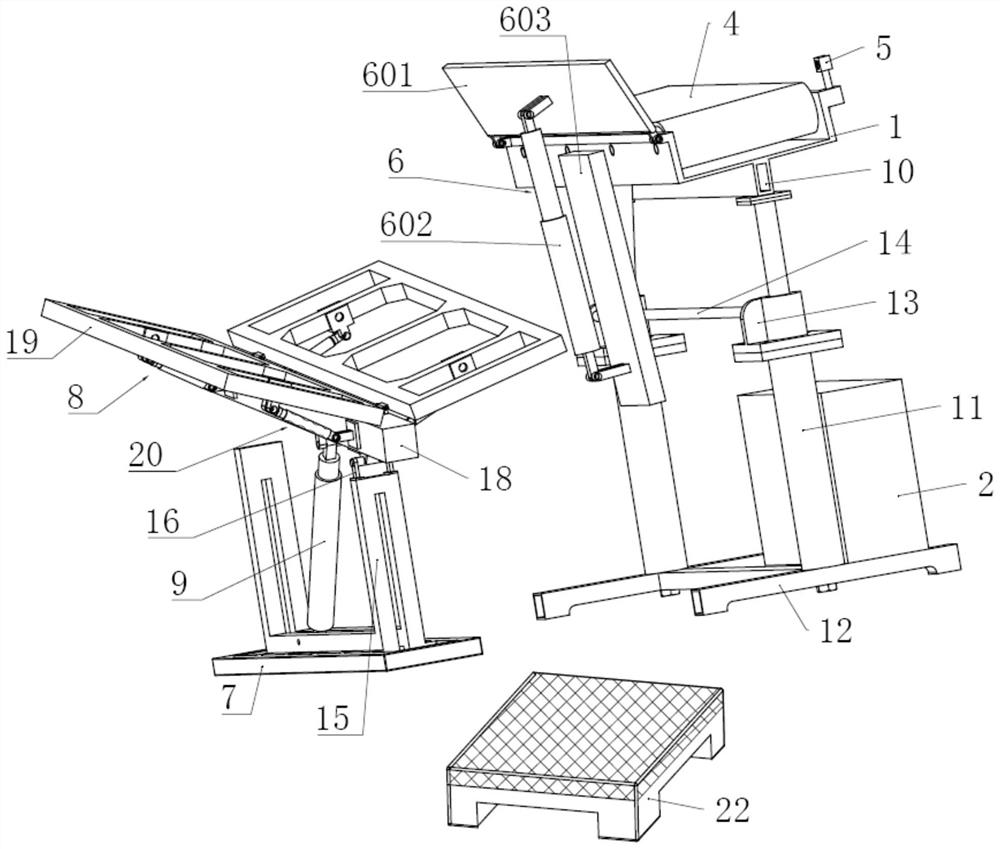

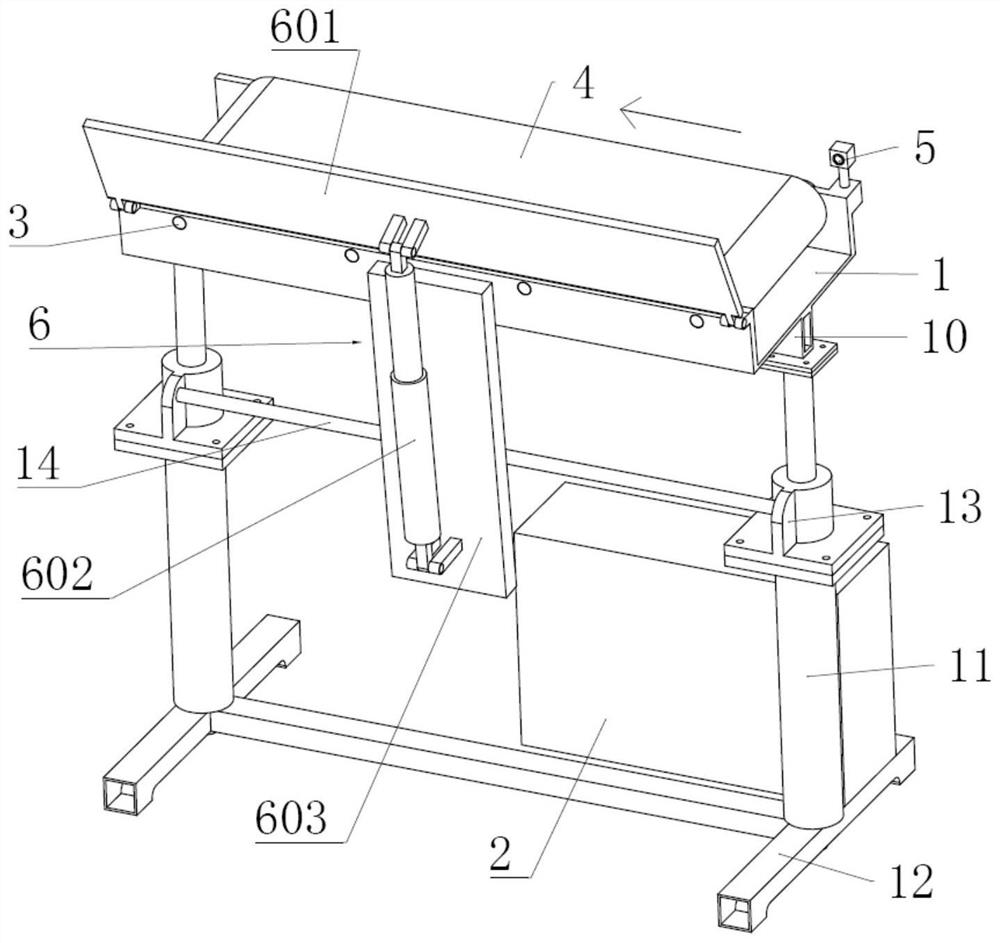

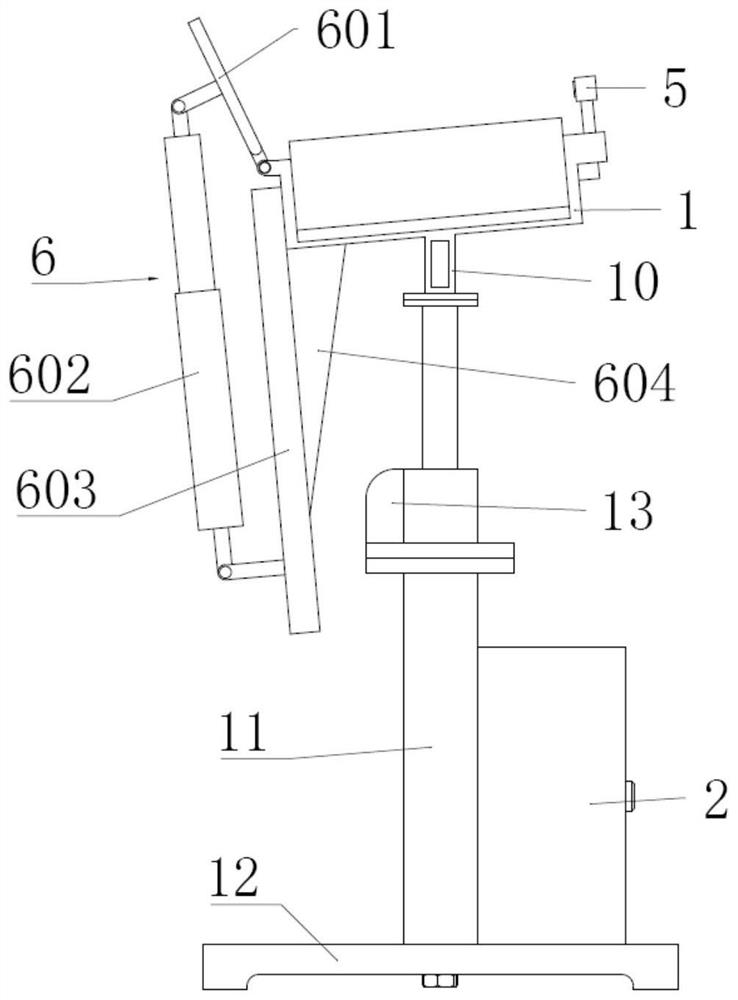

[0038] like Figure 1-Figure 2 As shown, a paper tube automatic erecting device includes a conveying transfer mechanism and a paper tube erecting mechanism, and the paper tube erecting mechanism is located on one side of the conveying transfer mechanism along the conveying direction;

[0039] The transport transfer mechanism includes a transport frame 1 that can be lifted and tilted. The bottom of the transport frame 1 is equipped with a control box 2. The control box 2 is equipped with a PLC controller and a power distribution cabinet. A number of transport rollers 3 are arranged on the transport fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com