Enhanced denitrification system and method suitable for high sludge concentration

A sludge concentration and denitrification technology, applied in chemical instruments and methods, adjustment methods for biological treatment, water/sludge/sewage treatment, etc. Try to slow down, reduce the amount of sludge, and improve the effect of denitrification capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

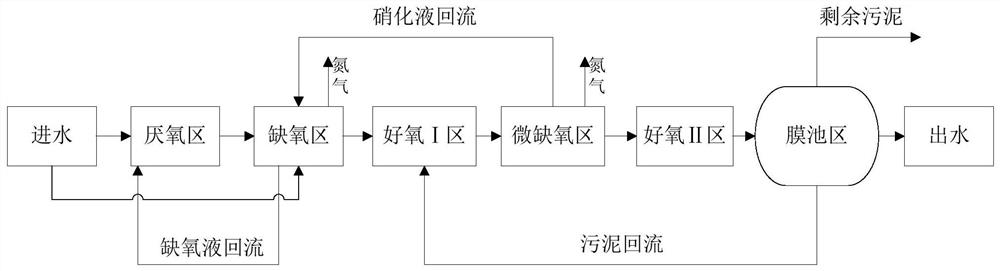

[0067] In this embodiment, an enhanced denitrification system suitable for high sludge concentration is specifically provided. The enhanced denitrification system includes: anaerobic zone, anoxic zone, aerobic zone I, micro-anoxic zone, and aerobic zone II area and membrane pool area, such as figure 1 As shown, its specific design is as follows:

[0068] In the anaerobic zone and the anoxic zone, water inlet points are respectively provided to realize the effective utilization of carbon sources, which can increase the utilization rate of carbon sources by denitrifying bacteria.

[0069] The influent water at the inlet point passes through the anaerobic zone, the anoxic zone, the aerobic zone I, the micro-anoxic zone, the aerobic zone II and the membrane pool area, which are connected in sequence, and then denitrifies the effluent; among them, the membrane pool area is passed through The primary return flow returns the sludge to the aerobic zone I, so as to realize the return ...

Embodiment 2

[0075] On the basis of the enhanced denitrification system provided in Example 1, this example also provides an enhanced denitrification method suitable for high sludge concentration, aiming at low load of influent and unbalanced carbon-nitrogen ratio and accounting for The AAO / AO+MBR system with a small area can meet the requirement that the effluent total nitrogen is less than 10mg / L. This enhanced denitrification method includes:

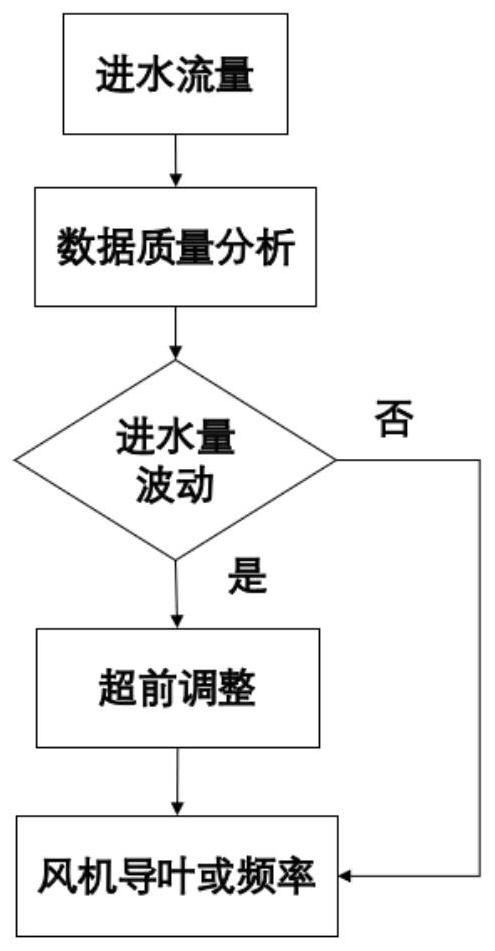

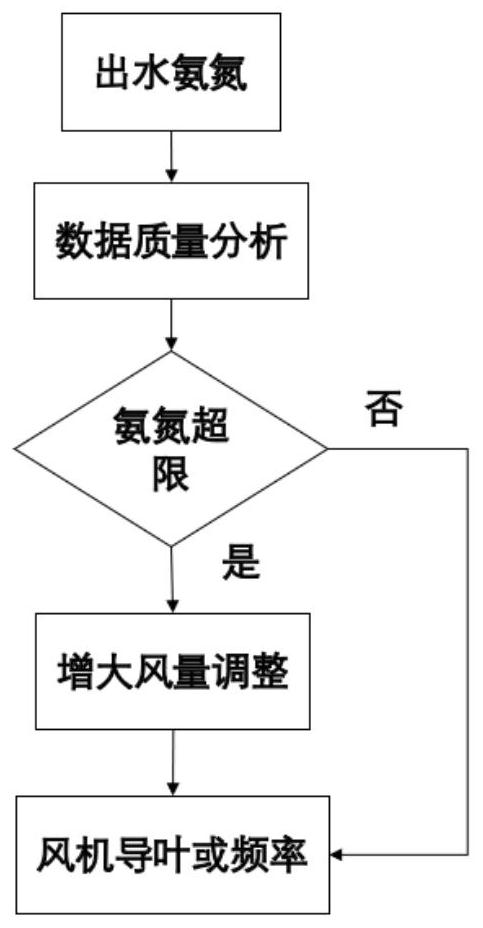

[0076] The anaerobic zone, the anoxic zone, the aerobic zone I, the micro-anoxic zone, the aerobic zone II and the membrane pool area are connected in sequence, and the anaerobic zone and the anoxic zone are respectively used as water inlet points, and the membrane pool area is used as the outlet water. point and discharge point of excess sludge. During operation, the automatic control in its technological process is divided into the following parts (sorting does not represent the order of steps):

[0077] ① PAC dosing dynamic control

[0078]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com