One-way moisture-conducting waterproof material and preparation method thereof

A waterproof material, moisture technology, used in chemical instruments and methods, film/sheet adhesives, synthetic resin layered products, etc. The problem of high permeability has the effect of reducing installation time and cost, and simplifying the construction process of waterproof sealing of gaps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

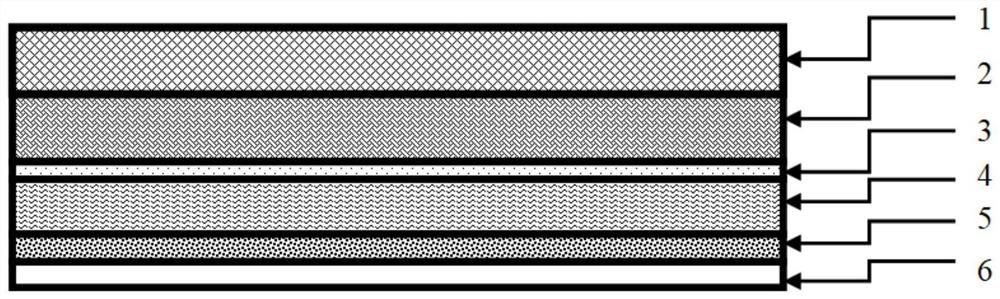

[0023] like figure 1 As shown, the unidirectional moisture-conducting waterproof material includes a waterproof reinforcing layer (1), a functional layer (2), an adhesive layer (3), a reinforcing layer (4), a pressure-sensitive adhesive layer (5) and a release paper (6).

[0024] The waterproof reinforcement layer (1) is a polyester non-woven fabric, the thickness of the polyester non-woven fabric is 100 μm, and the gram weight is 30 g / m 2 , The surface of the non-woven fabric is waterproof.

[0025] The functional layer (2) is a PTFE porous membrane, the fiber diameter of the PTFE membrane is 0.1-1 μm, the overall porosity is 50-75%, the thickness is 30 μm, and the gram weight is 15-20 g / m 2 .

[0026] The waterproof reinforcement layer (1) and the functional layer (2) are compounded by hot rolling. One side of the PTFE porous membrane and one side of the polyester non-woven fabric are fed into the hot rolling roll. The hot roll temperature is 250°C and the hot roll pressu...

Embodiment 2

[0031] like figure 1 As shown, the unidirectional moisture-conducting waterproof material includes a waterproof reinforcing layer (1), a functional layer (2), an adhesive layer (3), a reinforcing layer (4), a pressure-sensitive adhesive layer (5) and a release paper (6).

[0032] The waterproof reinforcement layer (1) is a polypropylene non-woven fabric, the thickness of the polypropylene non-woven fabric is 300 μm, and the gram weight is 100 g / m 2 , Because polypropylene itself is waterproof, no additional waterproof treatment is required.

[0033] The functional layer (2) is a PTFE porous membrane, the fiber diameter of the PTFE membrane is 0.1-1 μm, the overall porosity is 75-85%, the thickness is 50 μm, and the gram weight is 30-40 g / m 2 .

[0034] The waterproof reinforcement layer (1) and the functional layer (2) are compounded by hot rolling, and one side of the PTFE porous film and one side of the polypropylene non-woven fabric are fed into the hot rolling roll. The ...

Embodiment 3

[0039] like figure 1 As shown, the unidirectional moisture-conducting waterproof material includes a waterproof reinforcing layer (1), a functional layer (2), an adhesive layer (3), a reinforcing layer (4), a pressure-sensitive adhesive layer (5) and a release paper (6).

[0040] The waterproof reinforcement layer (1) is polyester / polypropylene meltblown cloth, the thickness of polyester / polypropylene meltblown cloth is 450μm, and the gram weight is 120g / m 2 , The mass ratio of polyester / polypropylene meltblown cloth is 70:30, because it contains polypropylene fiber, so polyester / polypropylene meltblown cloth is waterproof and does not need additional waterproofing treatment.

[0041] The functional layer (2) is a PTFE porous membrane, the fiber diameter of the PTFE membrane is 0.1-1 μm, the overall porosity is 85-90%, the thickness is 80 μm, and the gram weight is 60-70 g / m 2 ,

[0042] The waterproof reinforcement layer (1) and the functional layer (2) are compounded by h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com