Novel fullerene fiber blanket and manufacturing method thereof

A fullerene fiber, fullerene technology, applied in the direction of fiber chemical characteristics, dyeing method, rayon manufacturing, etc., can solve the problems of poor hygroscopicity of acrylic fiber, no health care effect on the human body, sultry and uncomfortable, etc. Eliminate the damage of oxygen free radicals, and the effect of lasting and novel flower pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

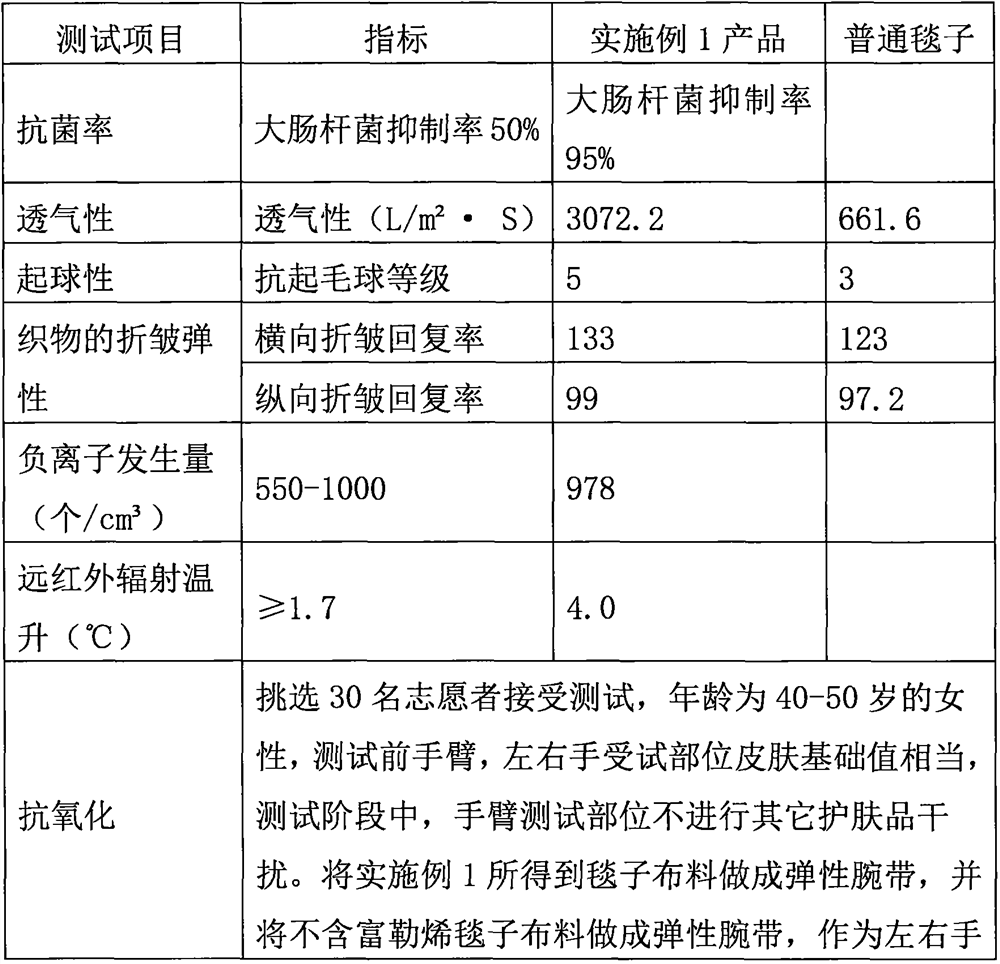

Embodiment 1

[0035] A) Raw material preparation, select the raw material for the noodle texture and the raw material for the bottom texture, use the DTY low elastic yarn containing fullerene and the specification of 150D as the raw material of the noodle yarn and the DTY low elastic yarn containing fullerene and the specification of 75D FDY polyester filament is used as the raw material of the bottom weave, and the mass percentage of the raw material of the surface weave in the fabric is 60%, and the mass percentage of the raw material of the bottom weave in the fabric is 40%. The fullerene DTY low elastic yarn and FDY polyester filament are obtained by adding 3% by mass fullerene masterbatch into polyester chip and melt spinning. Raw materials for surface texture and bottom texture are obtained.

[0036] B) warping, step A) obtains described fullerene DTY low elastic yarn as the raw material of face structure and the fullerene FDY polyester filament as bottom tissue raw material by warpin...

Embodiment 2

[0047] A) Raw material preparation, select as the raw material of the noodle texture and as the raw material of the bottom texture, use the DTY low elastic yarn containing fullerene and the specification of 100D as the raw material of the noodle yarn and the DTY low elastic yarn containing fullerene and the specification of 50D FDY polyester filament is used as the raw material of the bottom weave, and the mass percentage of the raw material of the surface weave in the fabric is 65%, and the mass percentage of the raw material of the bottom weave in the fabric is 35%. The fullerene DTY low-strength yarn and FDY polyester filament are obtained by adding 1% by mass fullerene masterbatch into polyester chips and spinning them through melt spinning. Raw materials for surface texture and bottom texture are obtained.

[0048] B) warping, step A) obtains described fullerene DTY low elastic yarn as the raw material of face structure and the fullerene FDY polyester filament as bottom t...

Embodiment 3

[0059] A) Raw material preparation, select as the raw material of the noodle texture and as the raw material of the bottom texture, use the DTY low elastic yarn containing fullerene and the specification of 300D as the raw material of the noodle yarn and the DTY low elastic yarn containing fullerene and the specification of 100D FDY polyester filament is used as the raw material of the bottom weave, and the mass percentage of the raw material of the surface weave in the fabric is 76%, and the mass percentage of the raw material of the bottom weave in the fabric is 24%. The fullerene DTY low-strength yarn and FDY polyester filament are obtained by adding 12% by mass fullerene masterbatch into polyester chips and spinning them through melt spinning. Raw materials for surface texture and bottom texture are obtained.

[0060] B) warping, step A) obtains described fullerene DTY low elastic yarn as the raw material of face structure and the fullerene FDY polyester filament as bottom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com