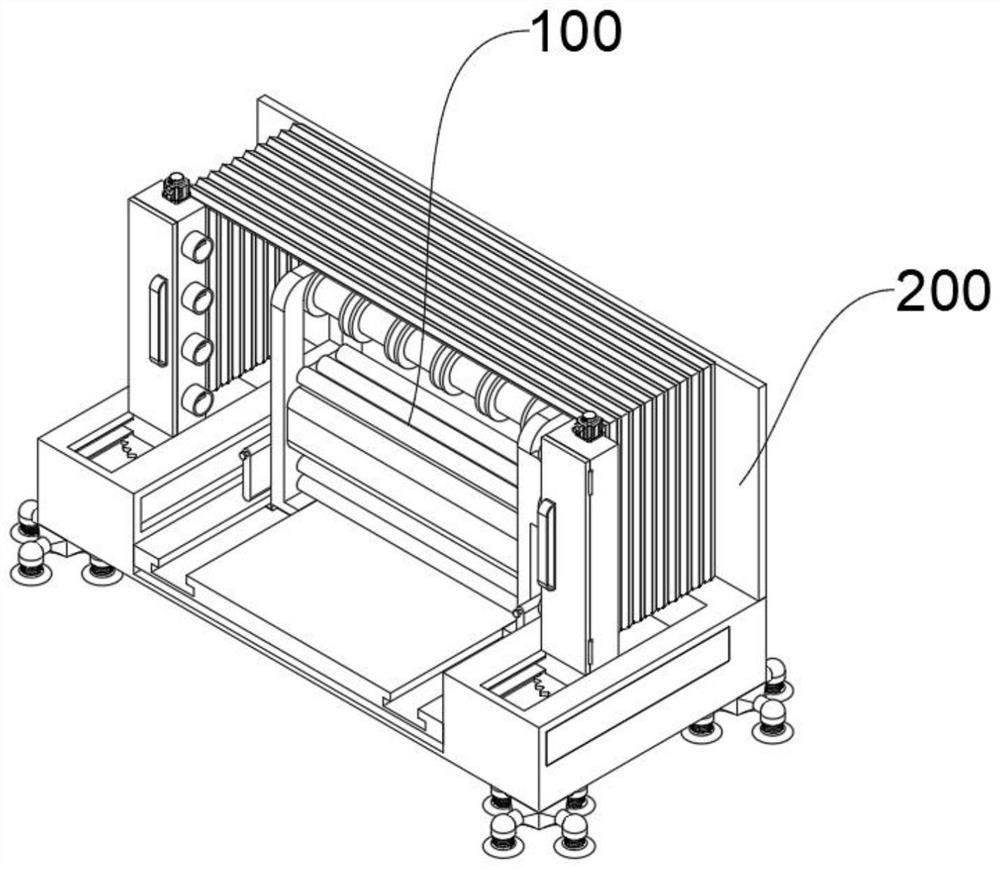

Noise reduction device for splicing warp knitting machine

A warp knitting machine and splicing technology, which is applied in warp knitting, mechanical equipment, knitting, etc., can solve the problems of unfavorable health of workers, lack of noise reduction devices, and erosion of workers, so as to reduce the harm of noise to the human body , Convenient shock absorption and noise reduction, and the effect of protecting your health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

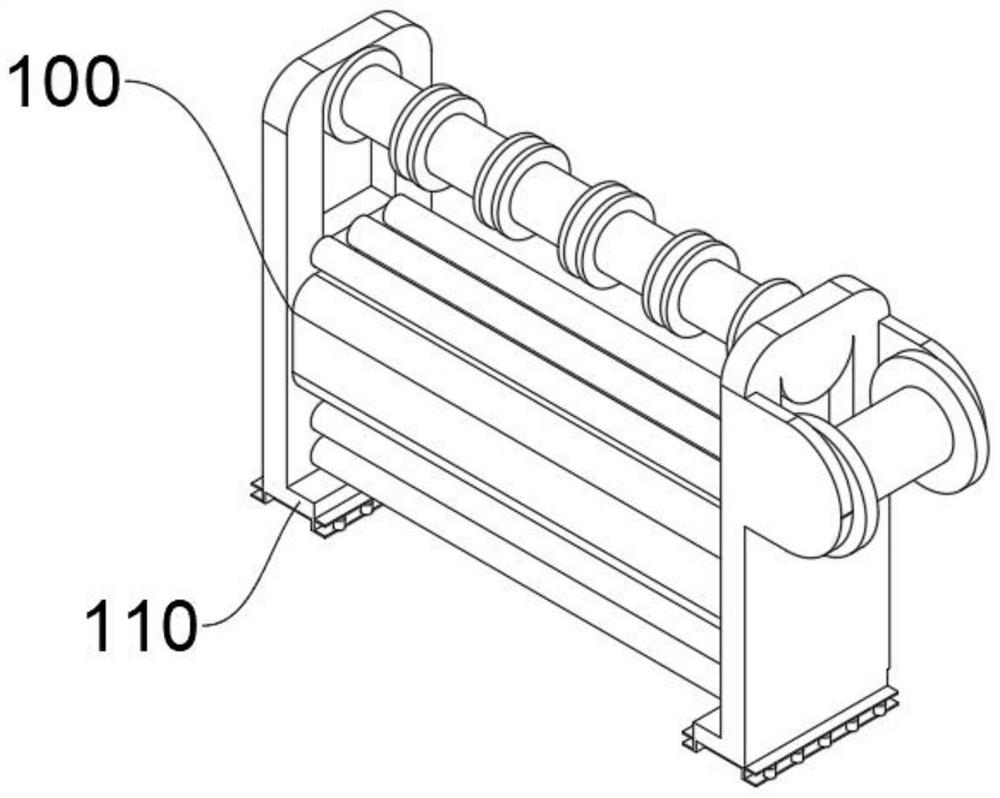

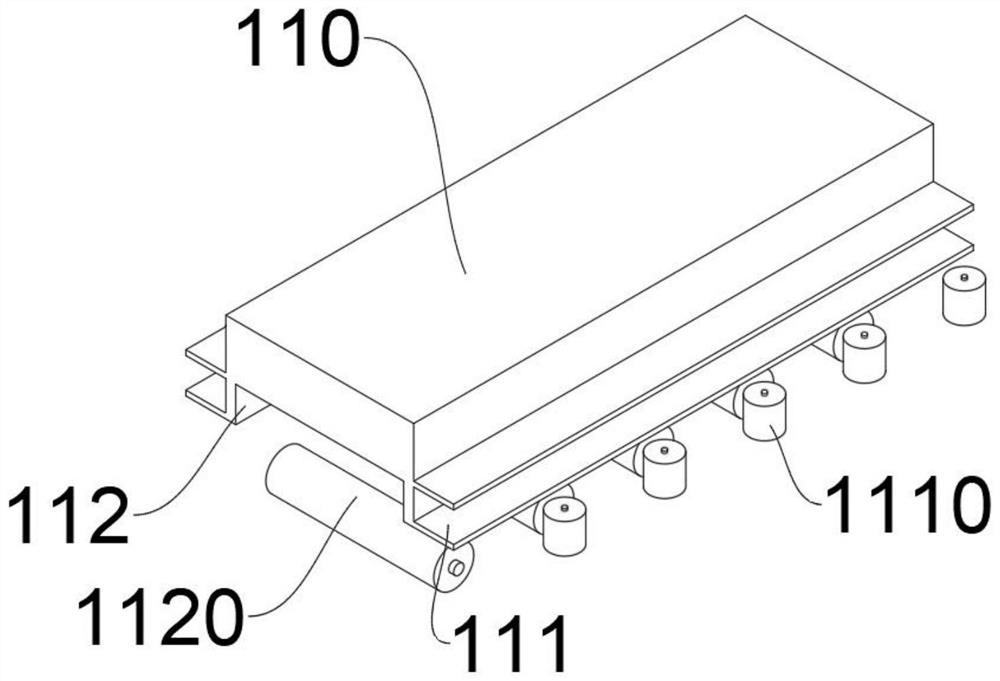

[0052] The support plate 210, the cross section of the support plate 210 is in a "U" shape, and the warp knitting machine body 100 is located in the center of the support plate 210

[0053] When the support plate 210 in the present invention is used specifically, the warp knitting machine body 100 is located inside the support plate 210, so that the support

[0059] It should be noted that the inner surface of the power plate 212 near the top is provided with a limit frame 2121, and the rack 2122 is located at the limit

[0062] Specifically, the clamping plate 214 is in the shape of a "cuboid", the clamping plate 214 is made of elastic rubber, and the outer wall of the clamping plate 214 is

[0065] Wherein, the inner cavity of the adjustment column 233 is rotated and provided with a transmission screw 234, and the end of the transmission screw 234 rotates and extends out of the adjustment column

[0066] Specifically, the outer wall of the cleaning frame 2351 is provided with a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com