Anti-collision assembly type steel bridge

A prefabricated, anti-collision technology, used in bridges, bridge parts, bridge construction, etc., can solve the problems of slippery pedal surface, reduced performance, poor braking effect, etc., to improve safety performance and improve braking effect. , the effect of avoiding casualties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

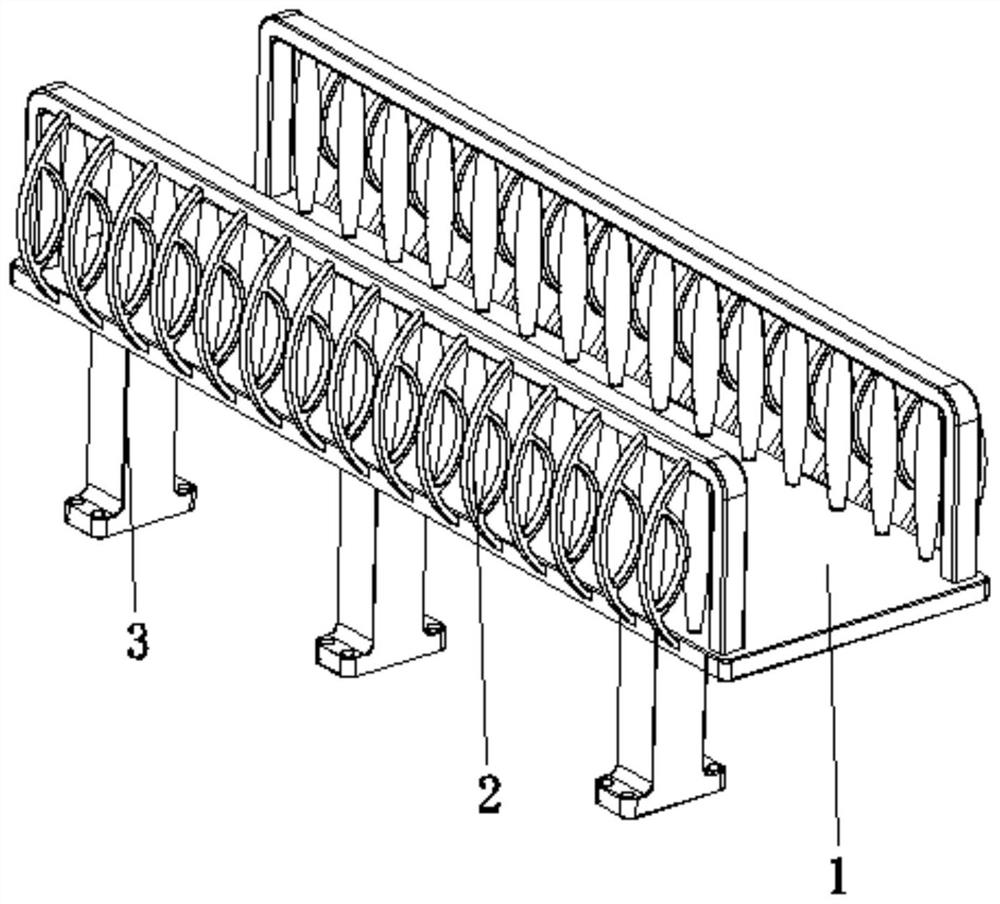

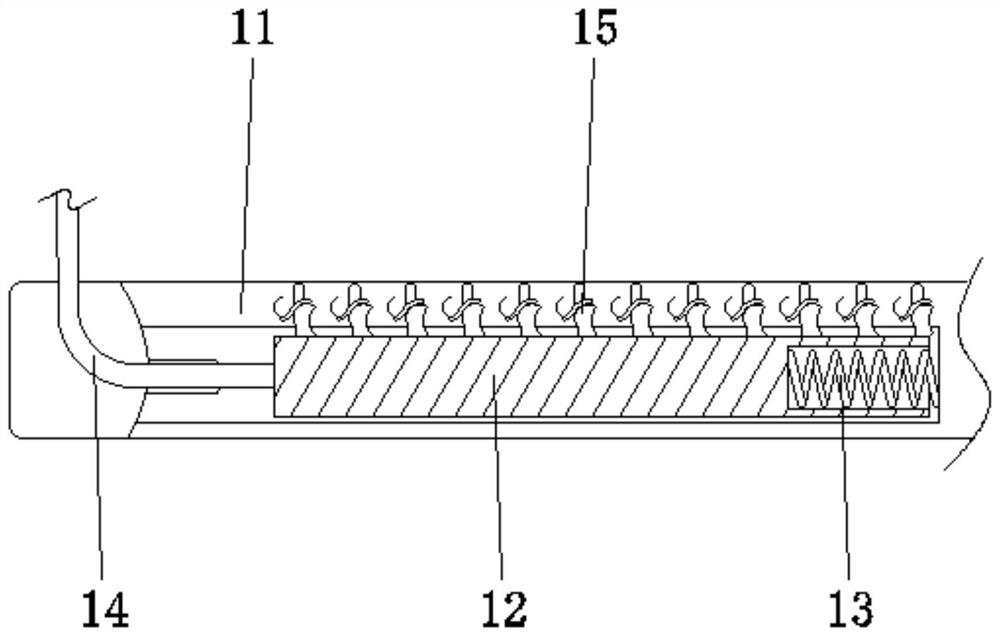

[0032] see Figure 1-7, the present invention provides a technical solution: an anti-collision assembled steel bridge, including a pedal device 1, a guardrail device 2, a support column 3, the guardrail device 2 is fixed on the two sides corresponding to the top of the pedal device 1, and the support column 3 Fixed on the central position of the bottom of the pedal device 1, the pedal device 1 is provided with a pedal body 11, a sliding plate 12, a return spring 13, a right-angle connecting rod 14, a friction device 15, the sliding plate 12 is slidably connected to the inside of the pedal body 11, and the return spring 13 is fixed between the two sides corresponding to the end of the sliding plate 12 and the inside of the pedal body 11. The right-angled connecting rod 14 is fixed on the end of the sliding plate 12 away from the return spring 13. The top of the right-angled connecting rod 14 is aligned with the surface of the guardrail device 2. The side is fixedly connected, a...

Embodiment example 2

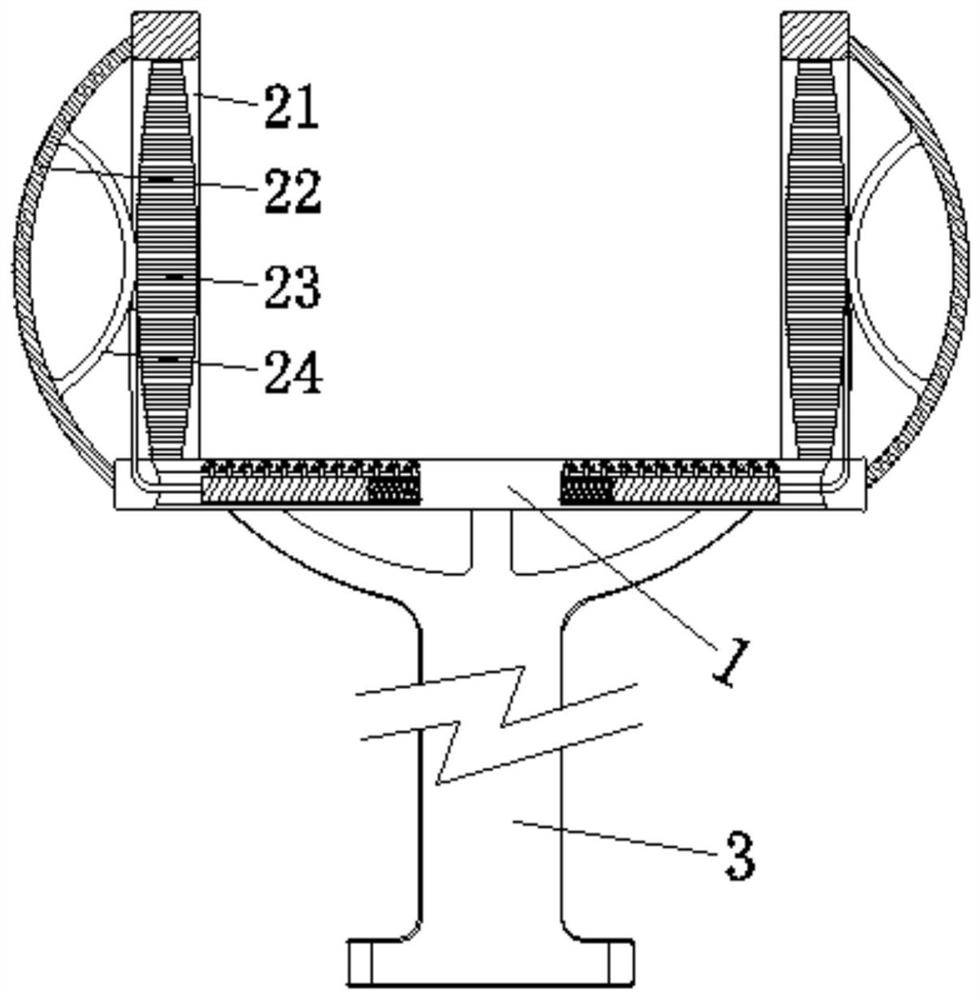

[0036] Guardrail device 2 is provided with U-shaped fixed mount 21, arc-shaped support 22, fence device 23, buffer member 24, and the opening of U-shaped fixed mount 21 is downward and is fixed on the top of pedal device 1, and arc-shaped support 22 is fixed on U Between the top of the surface of the U-shaped fixture 21 and the two sides corresponding to the surface of the pedal device 1, the barrier device 23 is fixed between the top of the inner wall of the U-shaped fixture 21 and the two sides corresponding to the top of the pedal device 1, and the buffer member 24 is fixed on Between the two sides corresponding to the surface of the barrier device 23 and the inner wall of the arc-shaped support 22, when being hit, the barrier device 23 is elastically deformed to provide a buffer distance and provide initial protection. At the same time, the arc-shaped support 22 can make the guardrail device 2 more stable , and provide support for the buffer member 24 at the same time, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com