Device and method for treating dredger fill by combining supercharged vacuum preloading with solar intermittent electroosmosis

A solar energy and soil filling technology, which is applied in the field of soil filling reinforcement treatment and soil reclamation engineering, can solve the problems of electroosmotic energy consumption, corrosion, large electrodes, etc. The effect of lifting, simple construction process and good airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

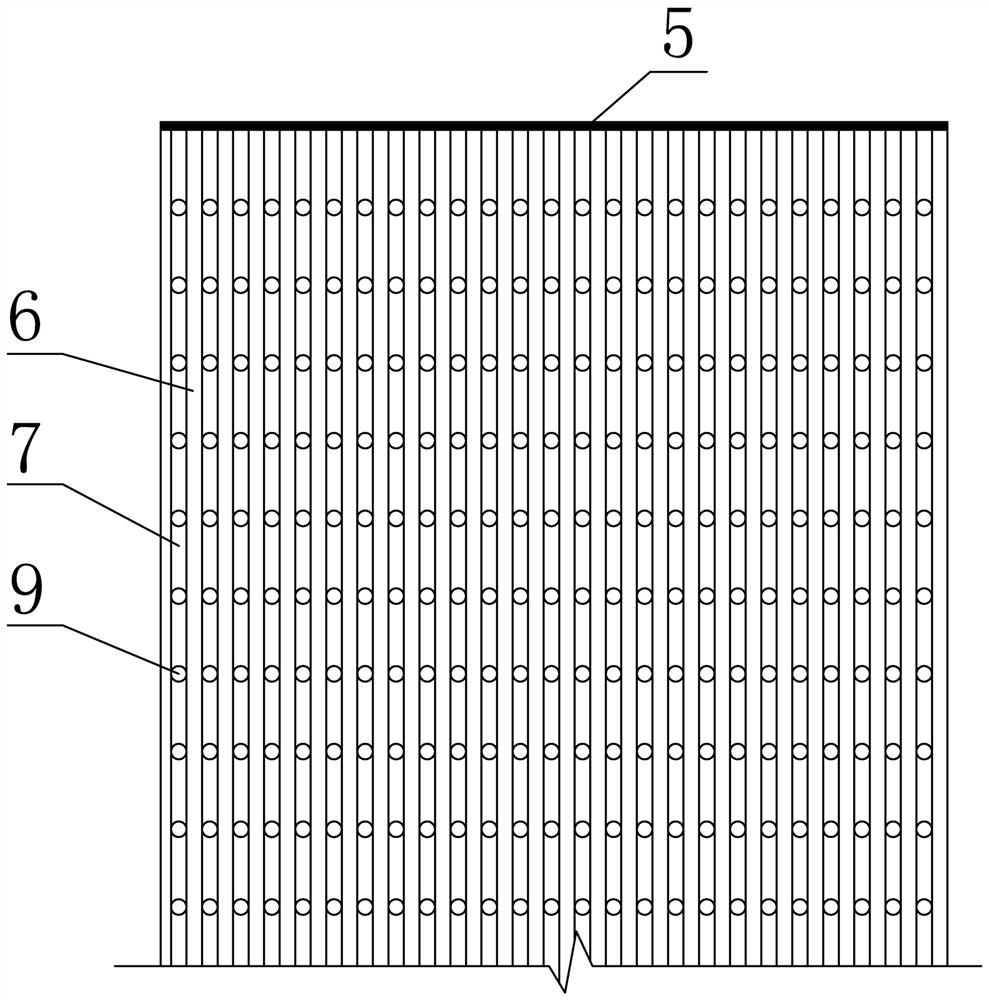

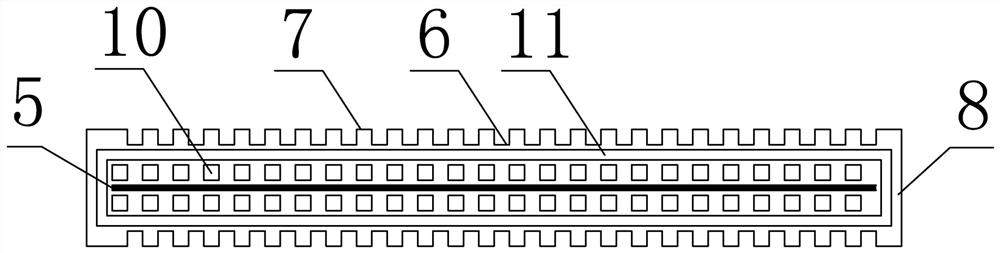

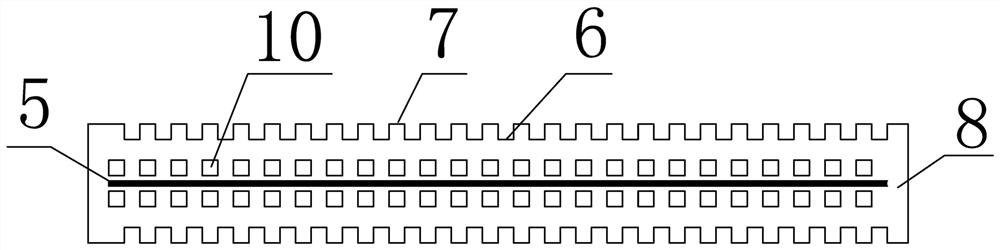

[0032] according to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 Composite hand joint 2, composite electric booster drainage board 1, tee joints 25.1, 25.2, vacuum splitter 22.2, booster splitter 22.1, vacuum pump 21, booster pump 20, solar panel 23, cables 24.1, 24.2 , Experimental field 19, on the basis of the metal copper fiber mesh 5, the feature is that the composite electric booster drainage board 1 is composed of 8 substrates with front, middle and rear layers superimposed, and the surface of the substrate 8 is wrapped with a layer of conductive Geotextile filter membrane, the front and rear substrates are vacuum drainage boards 3, the middle layer is a pressurized board 4, there are protrusions and longitudinals 7 arrayed on the outer surface of the vacuum drainage board 3, and the gap between two adjacent longitudinals is Drainage grooves 6 are formed, and a row of pressurization holes 9 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com