Self-setting mortar and method for anti-seepage and strengthening of embankment

A mortar and self-congealing technology, which is applied in sea area engineering, construction, water conservancy engineering, etc., can solve problems such as difficult to meet engineering needs, low strength, low stone rate, etc., to shorten the consolidation period, improve the consolidation rate, and impermeability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

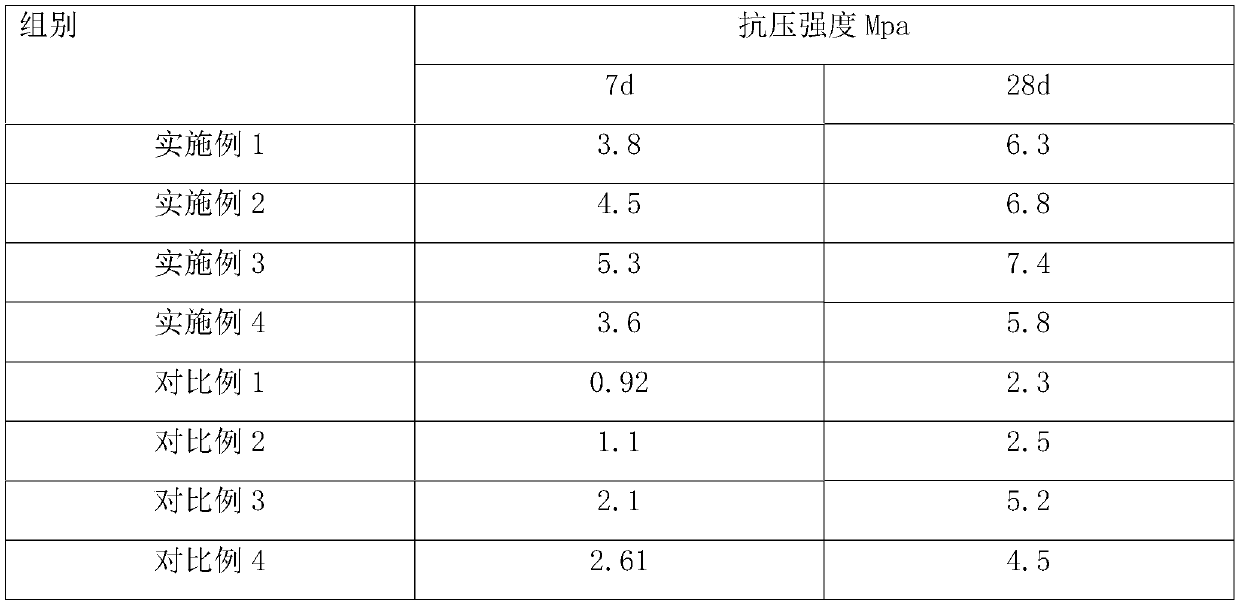

Examples

Embodiment 1

[0053] A self-setting mortar, consisting of the following components by weight:

[0054] 48 parts of bentonite, 30 parts of fly ash, 192 parts of cement, 1.5 parts of sodium hydroxide, 1 part of sodium metaaluminate, 1 part of sodium silicate, 0.6 parts of retarder, 3 parts of reinforcing agent, 960 parts of water;

[0055] in,

[0056] The reinforcing agent is lignocellulose and diatomaceous earth with a mass ratio of 5:1;

[0057] The retarder is cyclodextrin and calcium lignosulfonate with a mass ratio of 1:5.

[0058] The particle size of the fly ash is 80 μm; the particle size of the lignocellulose is 800 nm; the particle size of the diatomite is 50 μm;

[0059] The preparation method of above-mentioned self-setting mortar, specifically is:

[0060](1) Mix bentonite, fly ash, sodium hydroxide, sodium metaaluminate and water, mechanically stir for 2 hours, and leave standstill for 5 hours to obtain activated bentonite mud;

[0061] (2) adding sodium silicate, reinforci...

Embodiment 2

[0064] A self-setting mortar, consisting of the following components by weight:

[0065] 40 parts of bentonite, 20 parts of fly ash, 140 parts of cement, 0.9 parts of sodium hydroxide, 0.5 parts of sodium metaaluminate, 0.5 parts of sodium silicate, 0.4 parts of retarder, 1 part of reinforcing agent, 700 parts of water;

[0066] in,

[0067] The reinforcing agent is lignocellulose and diatomaceous earth with a mass ratio of 3:1;

[0068] The retarder is cyclodextrin and calcium lignosulfonate with a mass ratio of 1:7.

[0069] The particle size of the fly ash is 50 μm; the particle size of the lignocellulose is 500 nm; the particle size of the diatomite is 25 μm;

[0070] The preparation method of above-mentioned self-setting mortar, specifically is:

[0071] (1) Mix bentonite, fly ash, sodium hydroxide, sodium metaaluminate and water, mechanically stir for 1 hour, and let stand for 3 hours to obtain activated bentonite mud;

[0072] (2) adding sodium silicate, reinforcing...

Embodiment 3

[0075] A self-setting mortar, consisting of the following components by weight:

[0076] 42 parts of bentonite, 21 parts of fly ash, 165 parts of cement, 1 part of sodium hydroxide, 0.6 parts of sodium metaaluminate, 0.8 parts of sodium silicate, 0.5 parts of retarder, 2.5 parts of reinforcing agent, and 895 parts of water;

[0077] in,

[0078] The reinforcing agent is lignocellulose and diatomaceous earth with a mass ratio of 4:1;

[0079] The retarder is cyclodextrin and calcium lignosulfonate with a mass ratio of 1:6.

[0080] The particle size of the fly ash is 75 μm; the particle size of the lignocellulose is 600 nm; the particle size of the diatomite is 40 μm;

[0081] The preparation method is the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com