Permanent magnet plate type closed swash plate type axial plunger pump and working method thereof

An axial plunger pump and plunger pump technology, applied in the pump, pump control, multi-cylinder pump and other directions, can solve the problems of high centrality requirements, complex structure, poor energy saving, etc., to simplify the installation and debugging process, the overall structure The effect of compactness and avoidance of flow leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

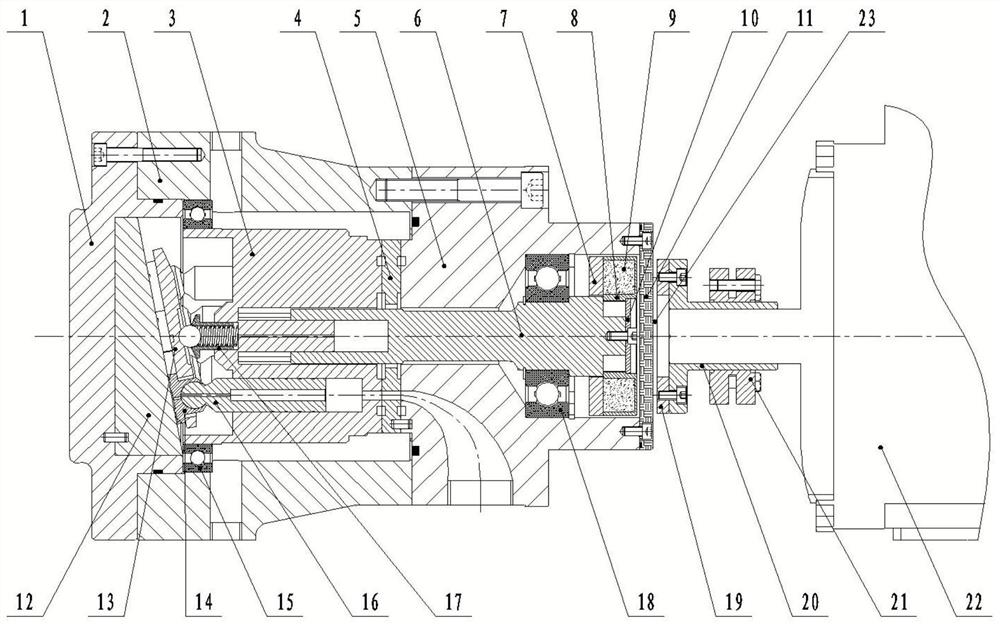

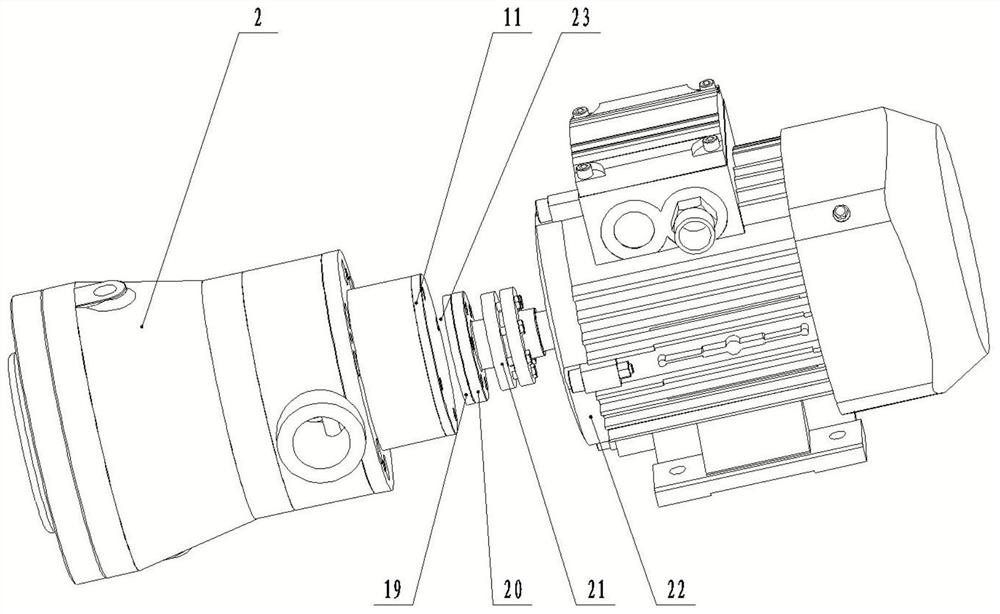

[0026] like Figure 1 to Figure 3 As shown, a permanent disk type closed swash plate axial piston pump in this embodiment 1 includes: a plunger pump body 2, a plunger pump front cover 5 installed at the front and rear ends of the plunger pump body 2 And plunger pump rear end cover 1, central shaft 6, permanent magnetic disk 8, permanent magnetic disk retaining cover 10, plunger pump front end cover 11 and conductor copper disc 19.

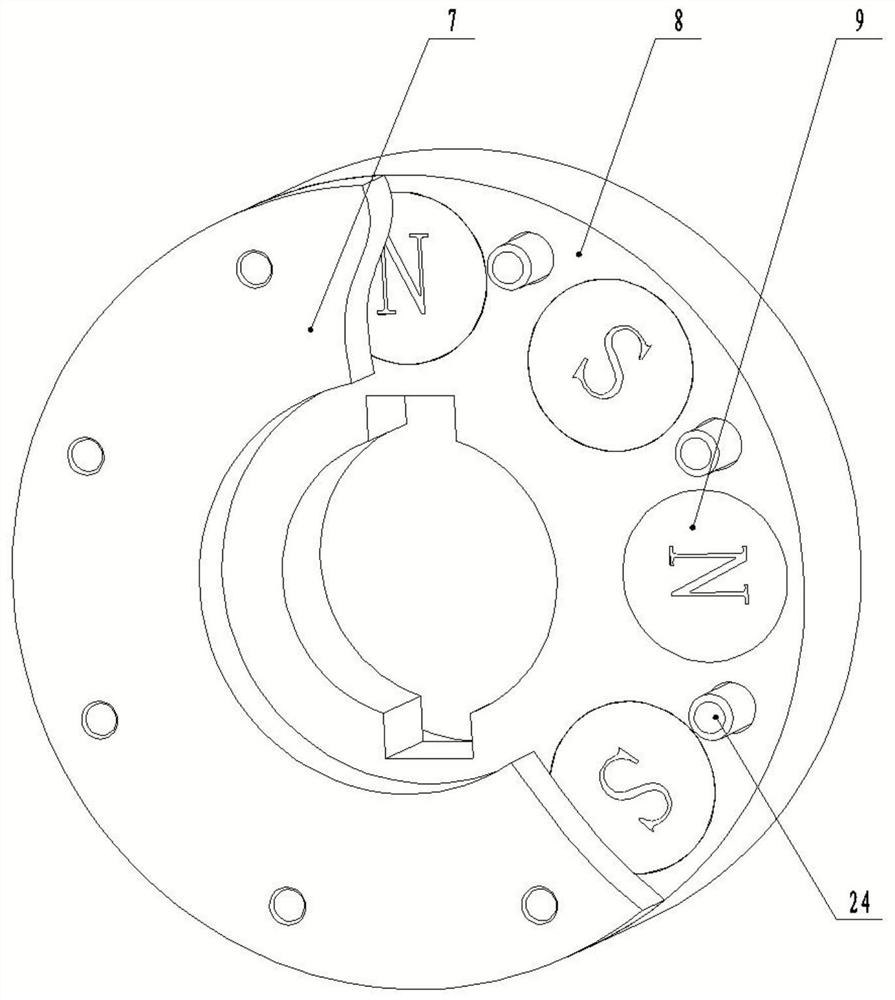

[0027] The central shaft 6 is installed in the plunger pump front cover 5 through the bearing 18, and one end of the central shaft 6 is connected with the plunger pump cylinder 3 through a spline, and the rotation of the central shaft 6 drives the plunger pump cylinder 3 to rotate, and the central shaft 6 The other end is connected with the permanent disk 8 by a key, and the permanent disk retaining cover 10 axially fixes the permanent disk 8 on the central shaft 6, and the rotation of the permanent magnetic disk 8 drives the central shaft 6 to rot...

Embodiment 2

[0035] The working method of a permanent disk type closed swash plate type axial piston pump in the present embodiment 2 comprises the following steps: After the permanent magnetic disk type closed type swash plate type axial piston pump is installed, the motor 22 runs to drive The conductor copper disk 19 rotates, and the conductor copper disk 19 and the permanent magnet 9 in the permanent disk 8 generate torque under the action of magnetic coupling, thereby driving the central shaft 6 to rotate, and the rotation of the central shaft 6 drives the plunger pump cylinder 3 to rotate in the plunger pump. The pump body 2 rotates, and the plunger 16 makes a reciprocating linear motion in the plunger hole, so that the volume of the plunger hole changes continuously, and the process of oil absorption and oil discharge is completed through the distribution plate 4 and the front cover 5 of the plunger pump.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com