Magnetic suspension bearing, magnetic suspension motor and compressor

A technology of magnetic suspension bearings and magnetic steel, which is applied in the fields of compressors, magnetic suspension bearings, and magnetic suspension motors, and can solve the problems of low utilization of magnetic steel and reduction of the overall axial output of bearings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

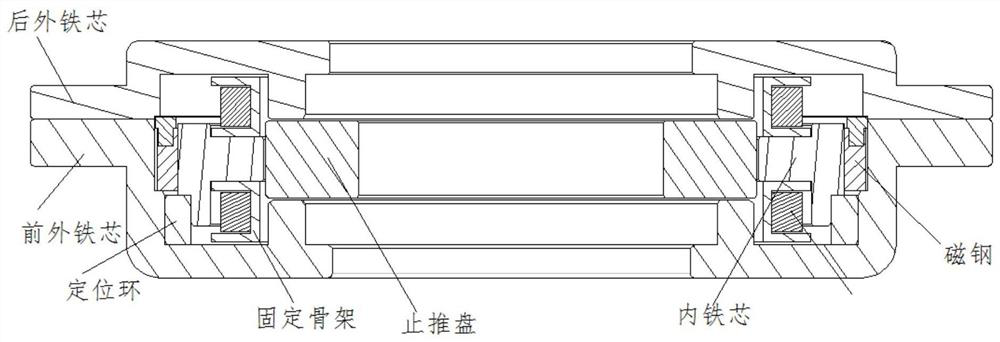

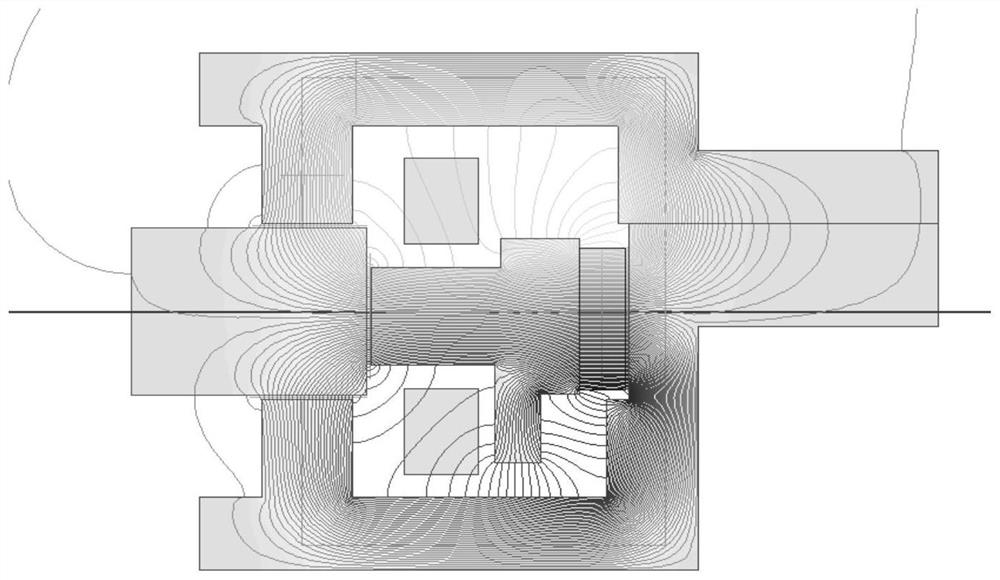

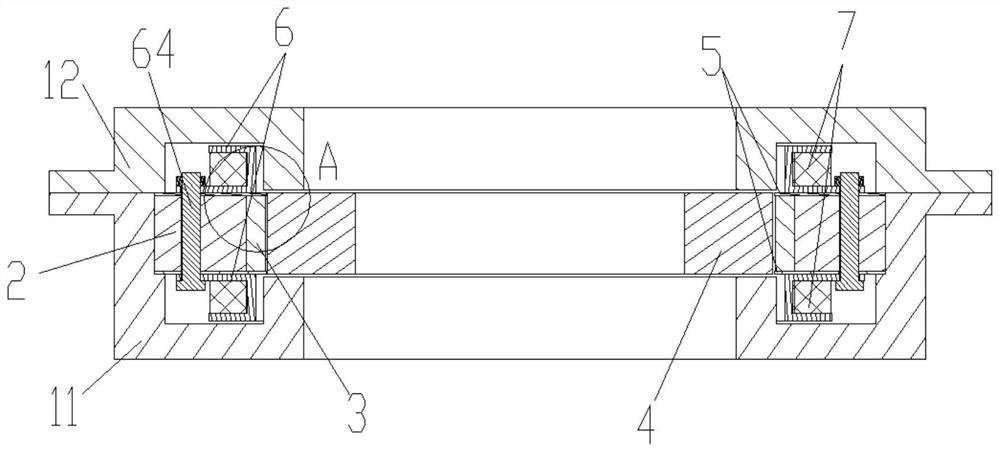

[0029] see in conjunction Figure 1 to Figure 9 As shown, according to the embodiment of the present invention, a magnetic suspension bearing is provided, including an outer iron core 1, an inner iron core 2 in the installation ring cavity of the outer iron core 1, and an inner ring wall of the inner iron core 2 The magnetic steel 3 is set, the outer ring wall of the inner iron core 2 is in contact with the cavity wall of the installation ring cavity, and the side of the magnetic steel 3 facing away from the inner iron core 2 is in contact with the thrust plate 4 Create a radial gap. In this technical solution, the inner iron core 2 is adjusted from the position between the magnetic steel and the thrust plate in the prior art to the side of the magnetic steel 3 away from the thrust plate 4, which can effectively avoid the magnetic steel 3. Excessive magnetic flux leakage can improve the utilization rate of the magnetic steel and thus increase the overall axial output of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com