Magnetic regenerator and manufacturing method thereof, magnetic working medium bed and magnetic refrigeration device

A production method and technology of magnetic working medium, which can be applied to household refrigeration devices, chemical instruments and methods, refrigerators, etc., and can solve the problems of small fluid resistance, small heat exchange area, and large fluid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

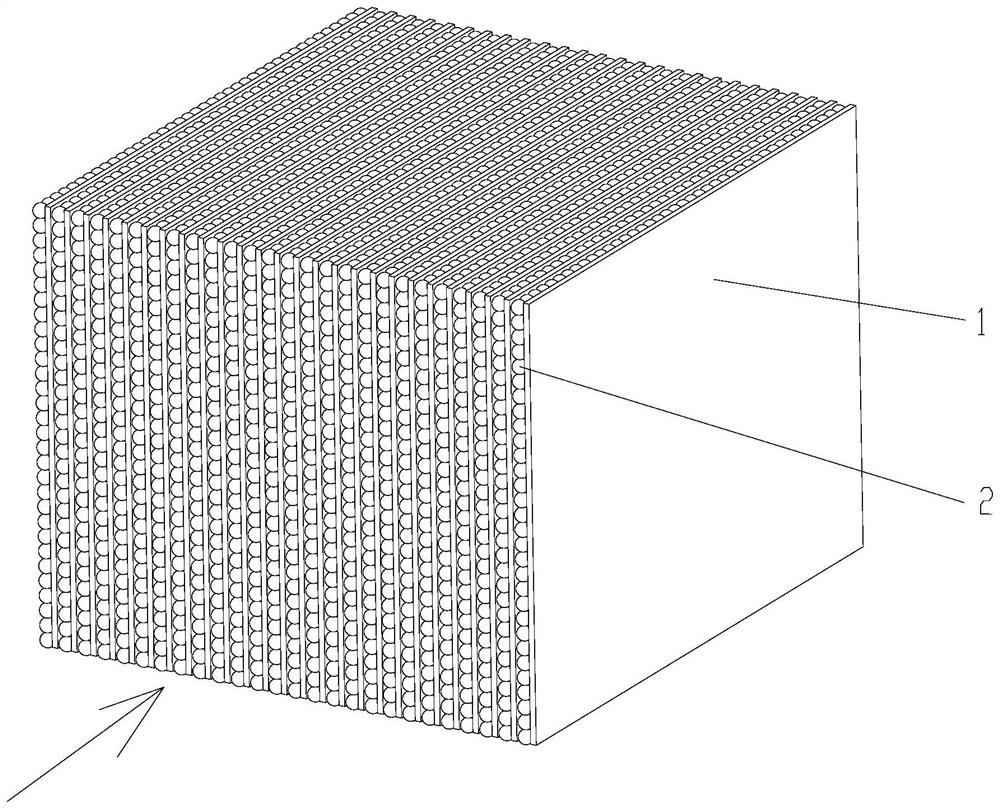

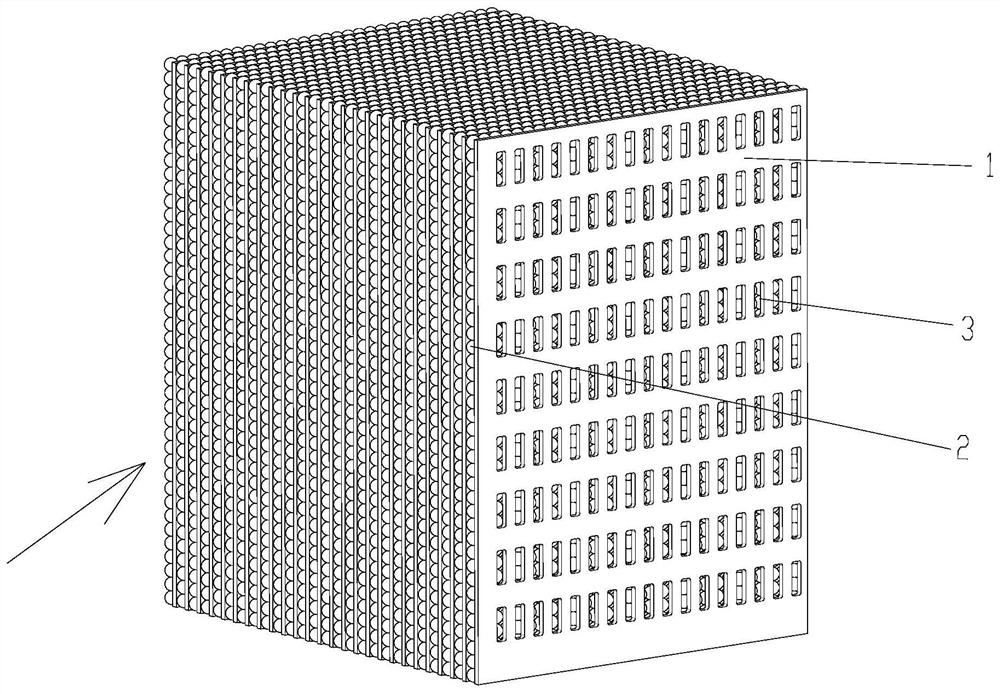

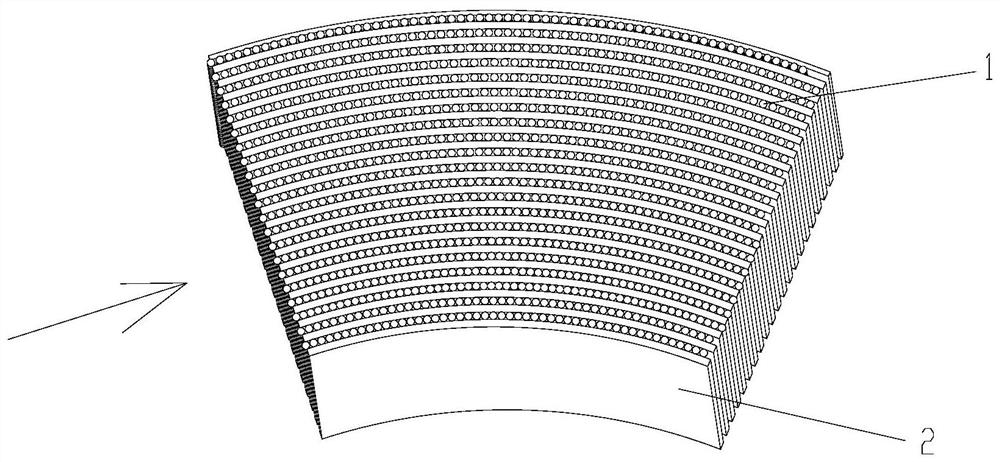

[0050]CombineFigure 1 to 8As shown, according to the embodiment of the present application, the magnetine cure comprises a sheet magnetic die 1 and a particle magnetic die 2, a plurality of sheet magnetic works, forming an adjacent sheet magnetic die 1. Fill space, particle magnetic die 2 filled in the filling space.

[0051]The magnetic reducing instrument binds the respective advantages of the particle magnetic dielectric heat transfer area and small flaps magnetic tuned loss, combining the two, so that the filler of the magnetic retriever is regular, and there is a large heat transfer specific surface area and Try to circulate the flow resistance of the magnetic retrielers as small as possible so that the viscosity loss formed is low, small flow resistance, high heat transfer performance, relatively simple, easy to process, so that the magnetic refrigeration device can effectively improve the magnetic refrigeration device Heating efficiency.

[0052]In one embodiment, the shape and / o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com