Energy-gathering joint-cutting pipe

An energy-gathering tube and energy-gathering technology, which is applied in the field of blasting, can solve problems such as difficult control of harmful effects, loss of life and property, over-excavation and under-excavation of rocks, etc., so as to reduce the unit consumption of explosives, uniform direction of energy-gathering slits, and harmless The effect of reducing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. It should be understood that the specific embodiments described here are only used to explain the present invention and are not intended to limit the present invention. .

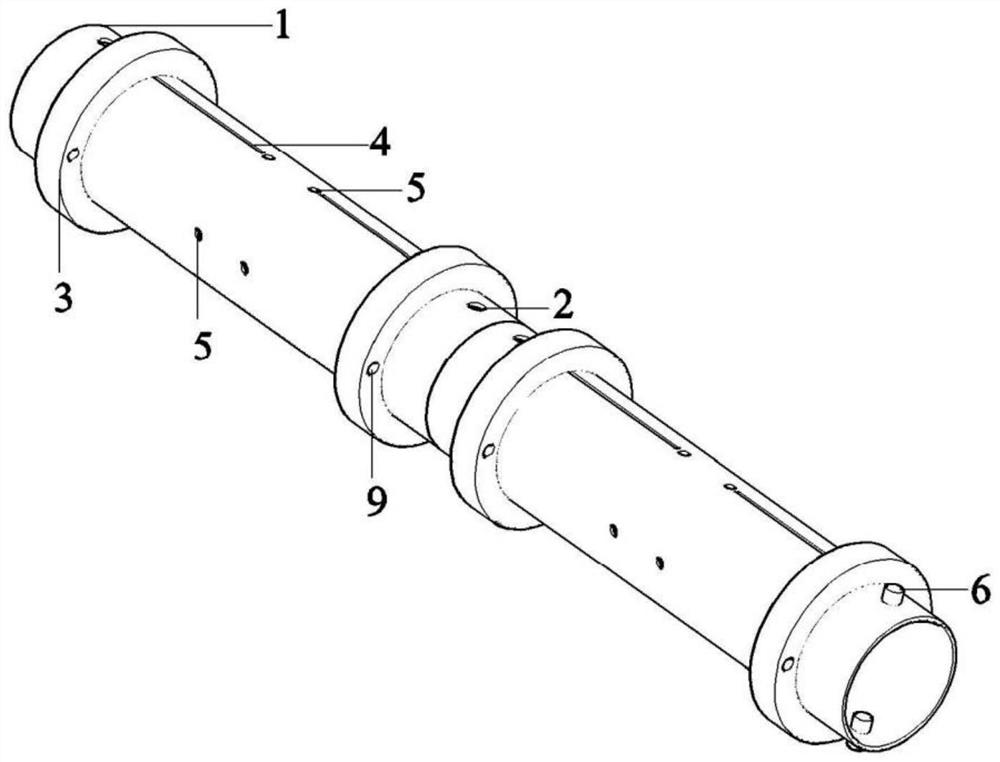

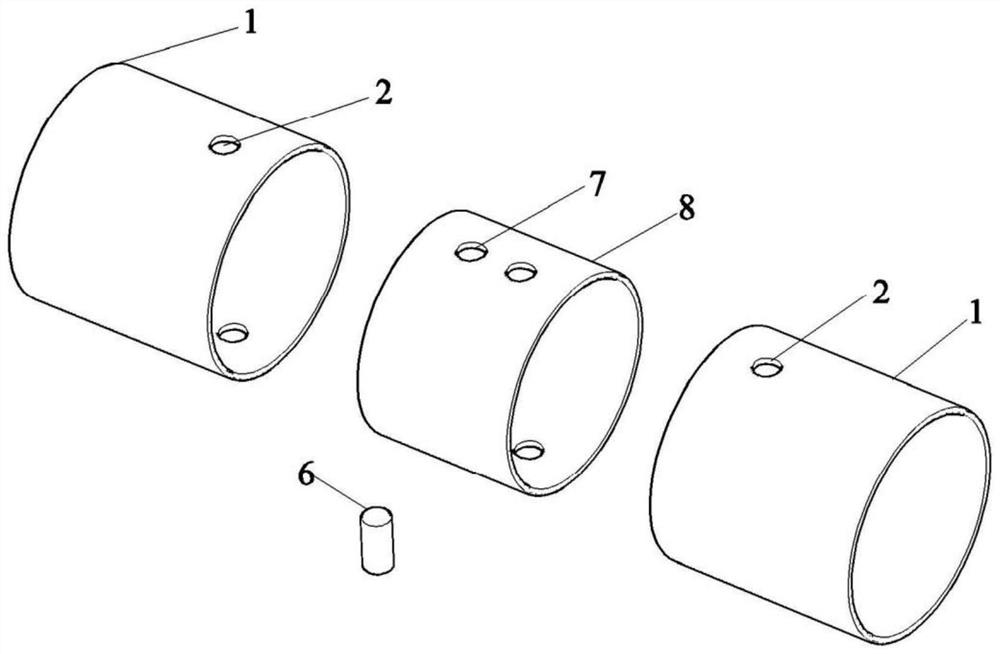

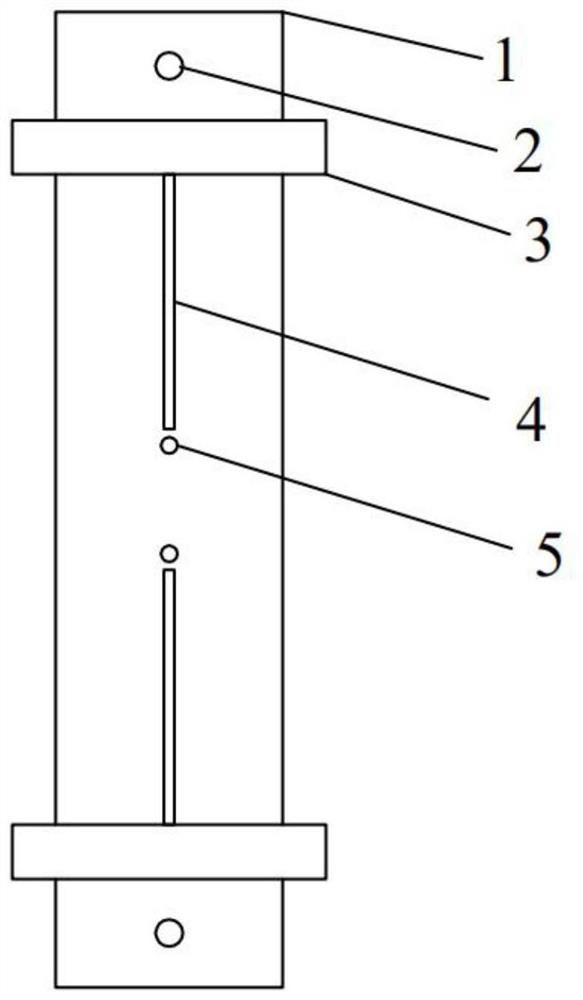

[0021] refer to Figure 1-Figure 5 As shown, an energy-gathering slit pipe device includes a pipe body 1, a first sleeve fixing hole 2, a centering foam 3, an energy-gathering slit 4, an air interval fixing hole 5, a fixing screw 6, and a second sleeve Fixing hole 7, sleeve 8, detonator line hole 9; the first sleeve fixing hole 2 is located at both ends of the tube body 1, the second sleeve fixing hole 7 is located at both ends of the sleeve 8, and the energy-gathering slit 4 is located at the tube body 1 Radial on both sides, and symmetrical to the central axis of the energy-collecting tube.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com