A kind of complex environment test system and test method of blade based on fiber grating sensor

A fiber grating and testing system technology, which is applied in the direction of aircraft component testing, instruments, measuring devices, etc., can solve the problems of large floor space, high maintenance costs, etc., and achieve the effects of fast processing speed, good accuracy, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

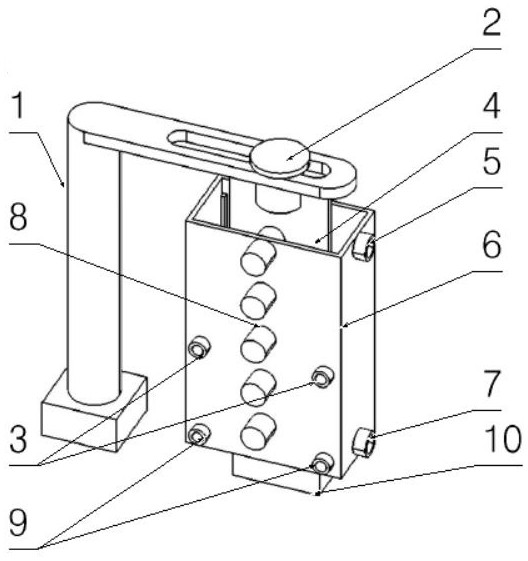

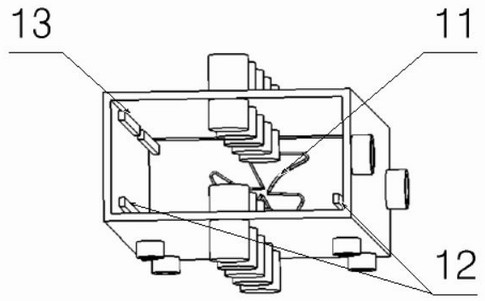

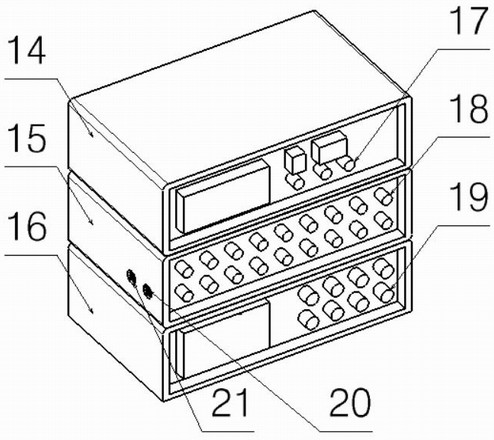

[0037] The present invention is a blade complex environment testing system based on a fiber grating sensor. The system structure includes a water tank testing device and an optical measuring device. The water tank testing device includes a blade to be tested. The generating device is used to simulate the strain of the blade at different working temperatures and when the temperature changes suddenly; the optical measuring device includes a broadband light source transmitter, a fiber coupler, and a fiber grating wavelength demodulator, which are used to generate the samples required for testing light source.

[0038] Further, the water tank testing device includes a fixed test bench, a blade fixing clip, an acrylic water tank, and a water tank fixing clip;

[0039] The fixed test bench is provided with a blade fixing clip, and the blade fixing clip hangs the blade to be tested on the fixed test bench; the blade fixing frame can move with multiple degrees of freedom and can also ...

Embodiment 2

[0051] The present application also mentions the blade complex environment test method of the above-mentioned system, and the test method includes the following steps:

[0052] S1, before the experiment, paste the FBG sensor on the surface of the blade as required, and paste the sensor protective cover on the blade to cover the FBG sensor to prevent the sensor from being affected by external factors;

[0053] S2, connect the FBG sensor to the fiber coupler, and connect the fiber coupler to the broadband light source transmitter and the fiber grating wavelength demodulator respectively;

[0054] S3, connect the relevant pipelines of the water tank, the inlet of the liquid nitrogen cooling device and the outlet of the liquid nitrogen cooling device; the water outlet of the water tank and the water inlet of the water tank are respectively connected;

[0055] S4, connect related equipment, connect the temperature monitoring device with an external display, and install it on figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com