A needle-like all-solid-state sensor for phenethylamine detection and its preparation method

A phenylethylamine and all-solid-state technology, applied in the field of neurotransmitter detection, can solve the problems of difficult to realize in vivo detection and large equipment, and achieve the effects of in vivo detection, reduced damage, and easy storage and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

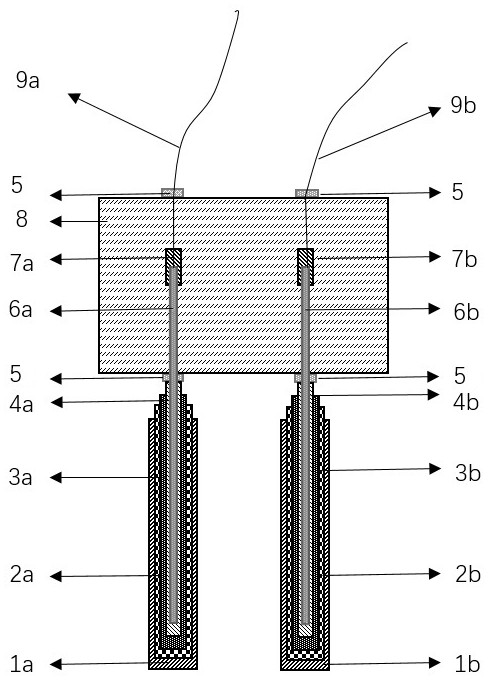

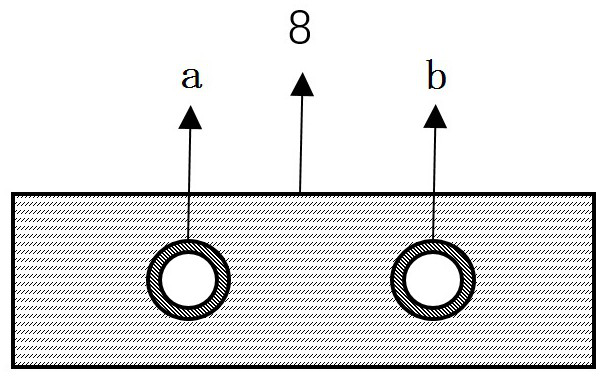

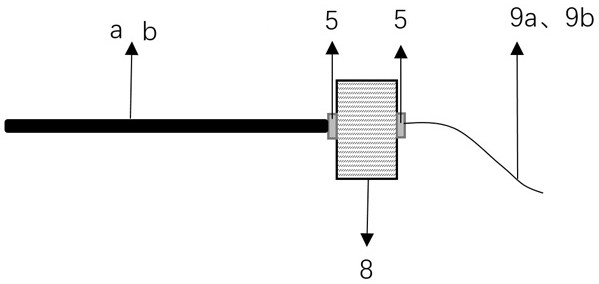

[0069] Such as figure 1 , figure 2 , image 3 As shown, a needle-shaped all-solid-state sensor for phenylethylamine detection includes a reference electrode b, a selective electrode a of phenylethylamine, and the phenylethylamine selective electrode includes the first gold wire 6a, One end of the first gold wire 6a is the selection output end, and the other end is sequentially coated with the solid electrolyte layer 4a, the phenethylamine sensitive membrane 3a, the macromolecule filter layer 2a and the soluble hardening layer 1a from the inside to the outside. The specific electrode includes a second gold wire 6b, one end is a reference output end, and the other end is covered with a solid electrolyte layer 4b, a reference membrane 3b, a macromolecule filter layer 2b and a soluble hardening layer 1b sequentially from inside to outside.

[0070] Preferably, the needle-shaped all-solid-state sensor further includes an electrode holder 8, a lead wire 9a of the selective electr...

preparation example 1S01

[0071] Preparation Example 1S01. Coat two gold wires with a diameter of 0.5mm and a purity of 99.999% with a Prussian blue insulating layer, and leave exposed parts at both ends for coating and detection ends; separate the two gold wire detection ends Use 1.5μm, 0.5μm and 0.05μm diameter alumina powder to prepare 80mg / mL alumina suspension to polish on the suede. After polishing, wash with deionized water and put in 50.0% vol alcohol solution Ultrasonic cleaning with 8.0%wt sulfuric acid solution for 10 minutes respectively, the power of ultrasonic cleaning is 200w, and then rinse with deionized water; finally, dry the exposed part of the gold wire with nitrogen gas without water droplets, and put it in a drying oven for drying for 20 hours;

[0072] S02. Coating a solid electrolyte layer: the poly-3,4-ethylenedioxythiophene monomer / polystyrene sulfonic acid aqueous solution with a mass concentration of 1.3 wt% poly-3,4- Based on the total mass of ethylenedioxythiophene monome...

preparation example 2

[0079] S01. Coat two gold wires with a diameter of 0.4mm and a purity of 99.99% with a Prussian blue insulating layer, and leave bare parts at both ends for coating and detection ends; The 100 mg / mL alumina suspension prepared with 1.2 μm, 0.8 μm and 0.07 μm diameter alumina powder was polished on the suede, cleaned with deionized water after grinding, and put into 45.0% vol alcohol solution and 10.0 The %wt sulfuric acid solution was ultrasonically cleaned for 10 minutes, and the power of the ultrasonic cleaning was 180w, then rinsed with deionized water, and finally dried with nitrogen to dry the exposed part of the gold wire without water droplets, and then dried in a drying oven for 15 hours;

[0080] S02. Coating a solid electrolyte layer: the poly-3,4-ethylenedioxythiophene monomer / polystyrene sulfonic acid aqueous solution with a mass concentration of 1.4% of a conductive polymer aqueous solution, and poly-3,4- with a mass concentration of 1.4wt%. Based on the total mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com