Metal crack detector based on macroscopic graphene conformal microstrip antenna and detection method

A technology of a microstrip antenna and a detection method, which is applied in directions such as antenna support/installation device, frequency measurement device, radiation element structure, etc., can solve the problems of poor detection accuracy, high price and short detection distance, etc. The effect of monitoring, convenient production and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

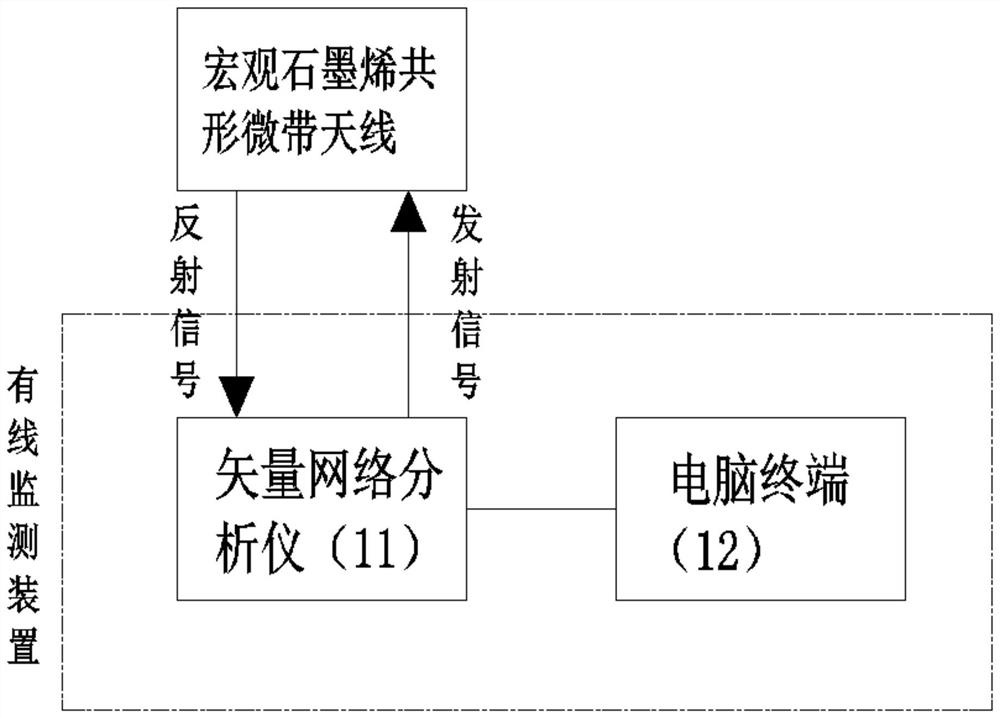

[0040] As an implementation, the wired detection device includes a vector network analyzer 11 and a computer terminal 12, the vector network analyzer 11 is connected with the macroscopic graphene conformal microstrip antenna, and the vector network analyzer 11 is used to The macroscopic graphene conformal microstrip antenna feeds, and receives the resonant frequency transmitted by the macroscopic graphene conformal microstrip antenna, and transmits the resonant frequency data to the computer terminal 12, and the computer terminal 12 is used to process the resonant frequency data Get the length and direction of the crack, and reflect the length and direction of the crack on the metal structure to be tested according to different frequency shifts;

[0041]As an implementation, the macroscopic graphene conformal microstrip antenna is provided with an SMA joint, and the vector network analyzer 11 is connected to the SMA joint by a coaxial line to realize real-time detection of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com