Cooling device for liquid injection of lithium ion battery and liquid injection method

A cooling device, lithium ion technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problem of increasing the risk of quality control in the battery storage process, increasing the storage pressure in the temporary storage area of the battery, and the difficulty of injecting liquid or electricity into the battery. Core injection and other problems, to achieve the effect of shortening the injection time, stable injection, and low cost of transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

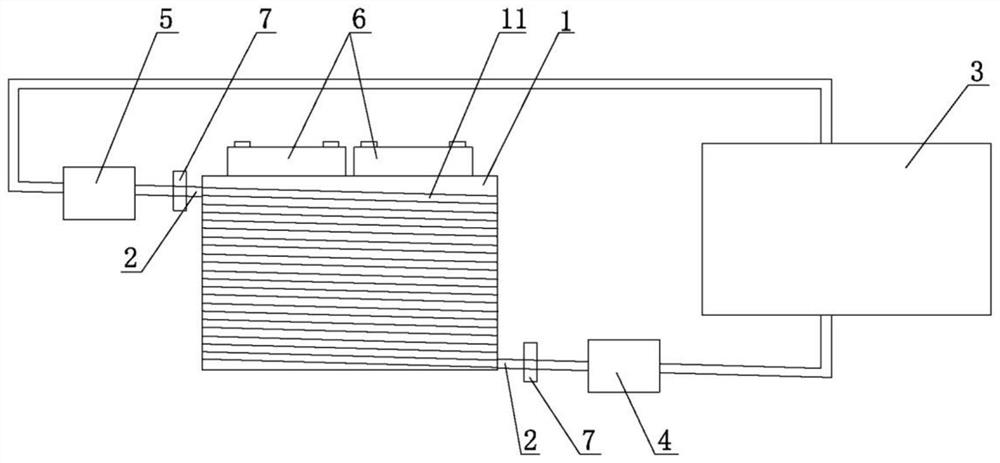

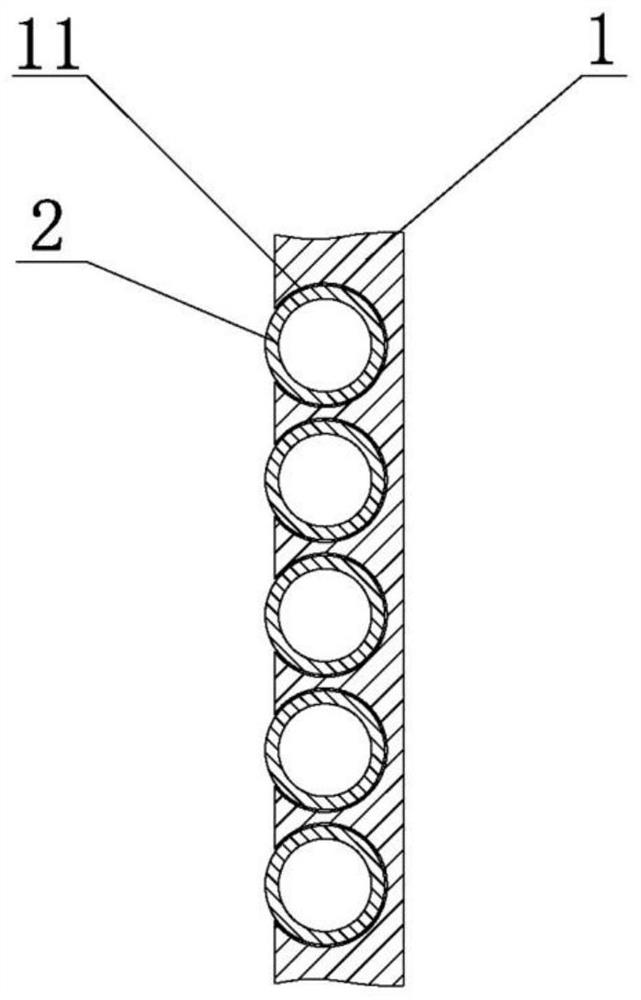

[0035] A 30Ah lithium iron phosphate aluminum shell cell was used as the experimental sample cell, and 48 cells just finished baking were selected for the experiment at a time.

[0036] The specific steps of the experiment are as follows:

[0037] 1. Put 48 cells into the cooling shell 1, and insert the temperature-sensing wire probe into the liquid injection hole of each cell (make sure that the probe is inserted into the upper end of the cell to hang in the air, and does not touch other components of the cell, and then Use tape to fix the temperature sensing wire on the outside), the temperature sensing wire is connected to a multi-channel thermometer, and the initial temperature inside the cell is measured to be 92 ℃ ~ 98 ℃; the condensate water pipe of the fixture is circulated with condensed water, where the condensed water is the temperature The ice water of about 0 ℃ ~ 5 ℃ is condensed for 30 ~ 35 minutes, and the internal temperature of the lithium ion battery drops to...

Embodiment 2

[0044] A 135Ah lithium iron phosphate cell was used as the experimental sample cell, and 48 cells just finished baking were selected for the experiment at a time.

[0045] The specific steps of the experiment are as follows:

[0046] 1. Put 48 cells into the cooling shell 1, and insert the temperature-sensing wire probe into the liquid injection hole of each cell (make sure that the probe is inserted into the upper end of the cell to hang in the air, and does not touch other components of the cell, and then Fix the temperature-sensing wire with tape outside), connect the temperature-sensing wire to the multi-channel thermometer, and measure the initial temperature inside the cell to be 100-110 °C; circulate the condensed water in the condensed water pipe of the fixture, wherein the condensed water is about It is ice water at 0°C to 5°C, and it is condensed and left for 30 to 45 minutes. After standing, the internal temperature of the lithium-ion battery drops to 45 to 50°C.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com