Surface acoustic wave resonator with double-layer POI structure and manufacturing method

A surface acoustic wave and resonator technology, applied in the field of high-performance surface acoustic wave resonators with double-layer POI structure and manufacturing, can solve the problems of low insertion loss, high out-of-band suppression passband edge roll-off, high Isolation, not meeting the high performance requirements of 5G communication, not fully meeting the operating frequency requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

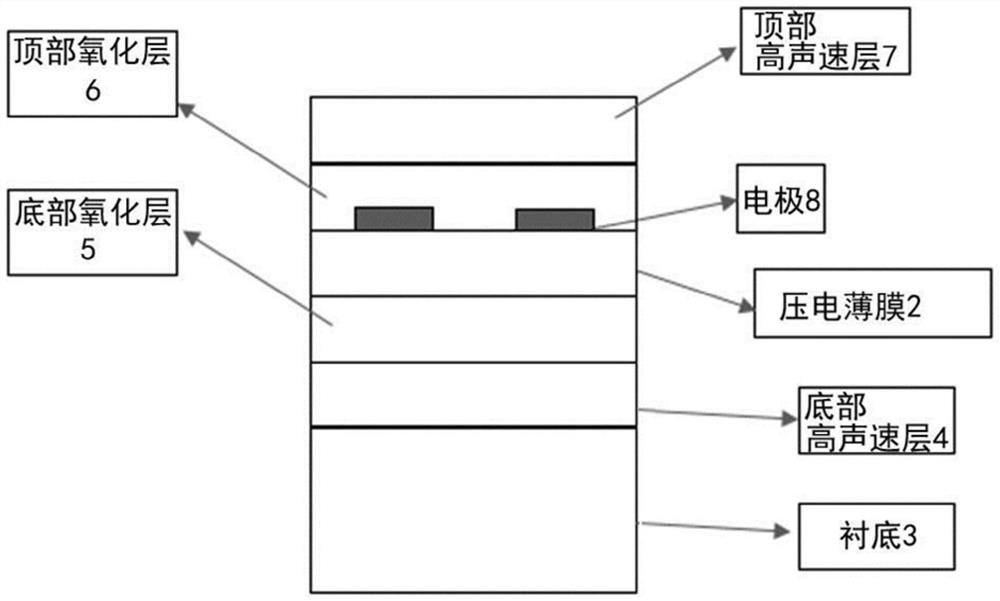

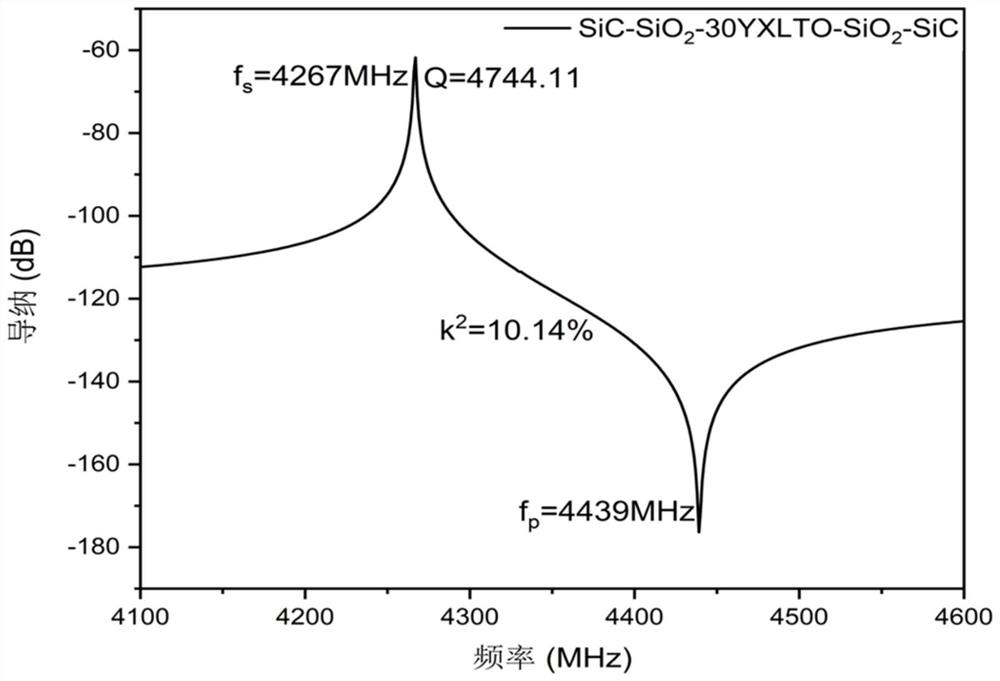

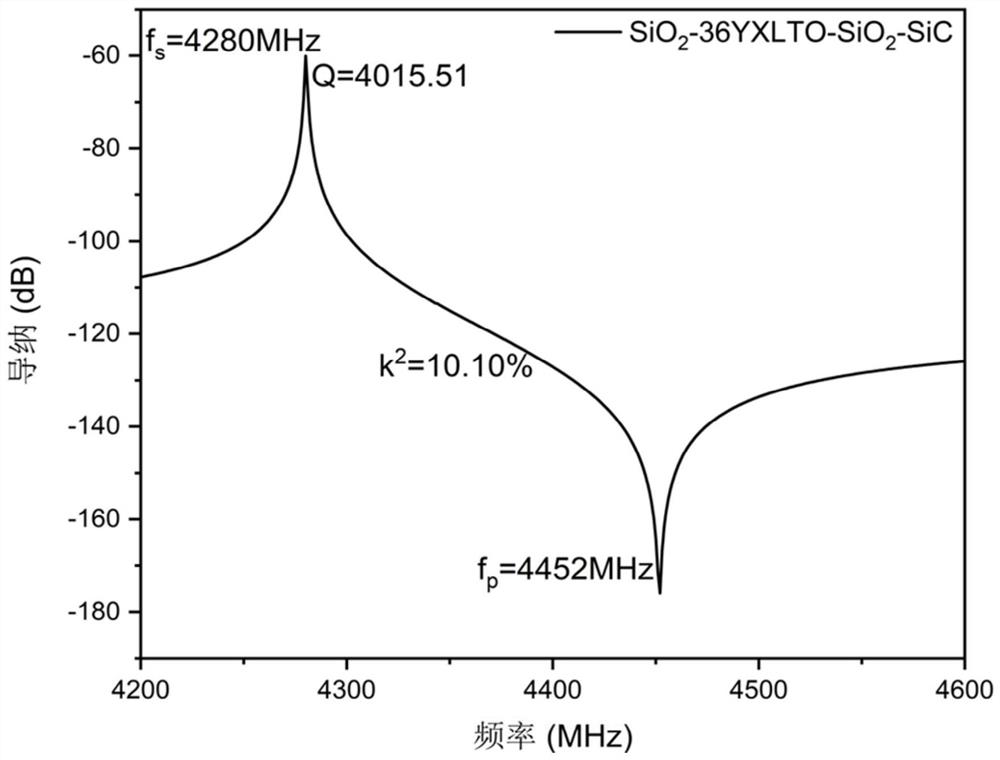

[0037] The present invention deposits a top oxide layer and a top high-sonic layer on the top of the IDT electrode. The top oxide layer and the top high-sonic layer together form the top POI structure. The thickness of the top oxide layer is adjusted according to product design requirements, preferably 0.2λ, and the top height The thickness of the sound velocity substrate is adjusted according to the product design requirements, preferably 0.4λ; the electrode is below the top oxide layer, and the electrode is preferably stacked with three metals of Ti, Pt, and Au. The electrode thickness is adjusted according to the product design requirements, preferably 0.07-0.08λ , where the thickness of Ti is thicker than that of Au; under the electrode is a piezoelectric film, and the piezoelectric material is preferably single crystal 30°YX LiTaO 3 、36°YX LiTaO 3 , 42°YX LiTaO 3 , its thickness is adjusted according to product design requirements, preferably 0.3λ; under the piezoelectri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com