A kind of intelligent cutting method and cutting system of solar cells

A solar cell, intelligent cutting technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of cutting error, small field of view, failure to meet production requirements, etc., to ensure consistency, improve accuracy, and avoid causing effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] A method for intelligently cutting solar cells is carried out as follows:

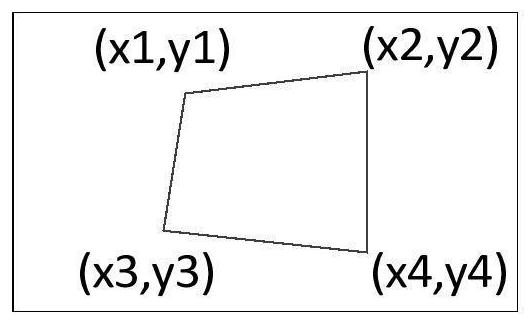

[0045] S1. Image extraction of the calibration board. The calibration board is a black A4 paper printed by a laser printer. Put the self-made calibration board on the cutting platform, and use the laser on the cutting platform to draw on the calibration board based on the origin of the laser cutting machine. A square with a length and width of 5mm, and then take pictures of the calibration plate through the camera on the cutting platform, and obtain the image of the calibration plate as follows: figure 1 shown, while figure 2 For an image of the actual calibration plate for the calibration plate, pass figure 1 and figure 2 It can be seen that the obtained picture is distorted. If it is not corrected, it will cause an error in accuracy when cutting the cell, making the cutting accuracy lower. At the same time, it will greatly increase the difficulty of cutting path analysis;

[0046] S2. Rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com