Lining structure of steel ladle for steelmaking emergency and building method of lining structure

A ladle and inner lining technology, which is applied to the inner lining structure and masonry field of steel ladles for emergency use in steelmaking, and can solve problems such as the complexity of the molten steel process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

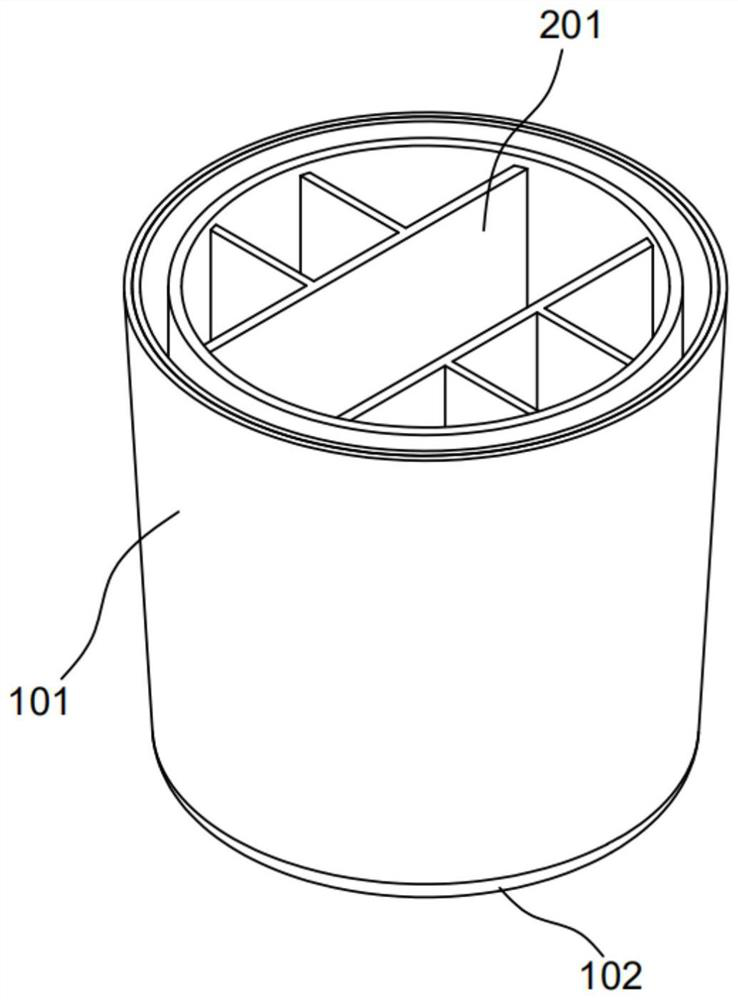

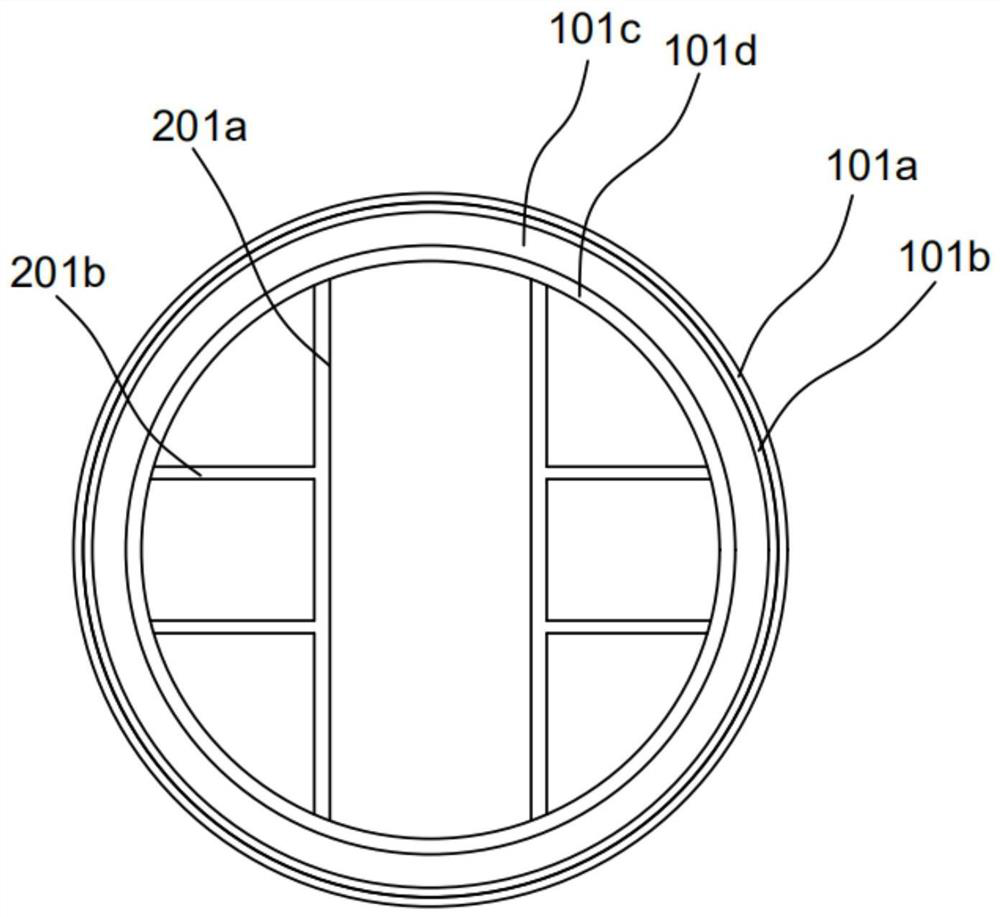

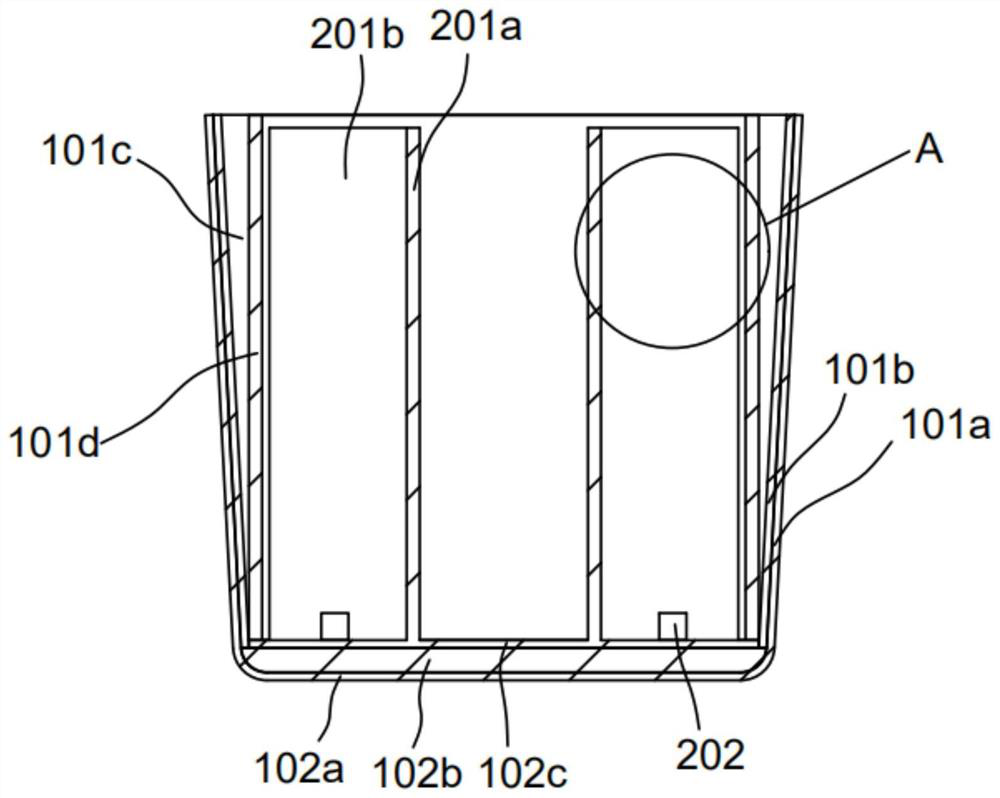

[0027] This embodiment provides a lining structure for steel-making emergency ladles, such as Figure 1-4 shown, including,

[0028] The ladle 100 includes a cladding wall structure 101 and a cladding bottom structure 102 arranged at the bottom of the cladding wall structure 101 ;

[0029] The cladding structure 101 includes a cladding 101a with a U-shaped axial longitudinal section. A permanent shell layer 101b is placed close to the inside of the cladding 101a. A working shell layer 101d is set inside the permanent shell layer 101b. The permanent shell layer 101b There is a gap 101c between the shell working layer 101d, the distance between the gap 101c is 0-170mm, and the gap 101c is filled with magnesia filler; the shell permanent layer 101b is made of 110mm thick high-alumina castable; the shell working layer 101d is made of 100mm Thick arc-shaped high-alumina brick masonry; the bottom cladding structure 102 includes a bottom shell 102a, a bottom permanent layer 102b is ...

Embodiment 2

[0035] A kind of masonry method for the inner lining structure of steel-making emergency ladle, such as Figure 1-4 shown, including,

[0036] S1: On the basis of the cladding and the bottom shell, the permanent layer of the shell and the bottom permanent layer are vibrated with high-alumina castables, and baked after construction;

[0037] S2: The working layer of the shell and the bottom working layer are constructed with high-alumina bricks, and the gap between the working layer of the shell and the permanent layer of the shell is filled while the working layer of the shell is being constructed;

[0038] S3: The prefabricated unit is built with aluminum-magnesium refractory mud inside the ladle to form a "well"-shaped prefabricated part;

[0039] S4: leave it for 24 hours naturally.

[0040] For the construction of the permanent layer of the shell, high-alumina castables are used for vibration construction, and the amount of water added is 7.5% of the mass of the castable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com