A steelmaking slag conveying production line and its control system

A technology of control system and production line, applied in general control system, control/regulation system, conveyor control device, etc., can solve the problems of unable to meet the requirements of slag particle size, unable to guarantee slag batching ratio, need to stop operation, etc., to achieve realization Work efficiently, ensure quality stability, and ensure cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

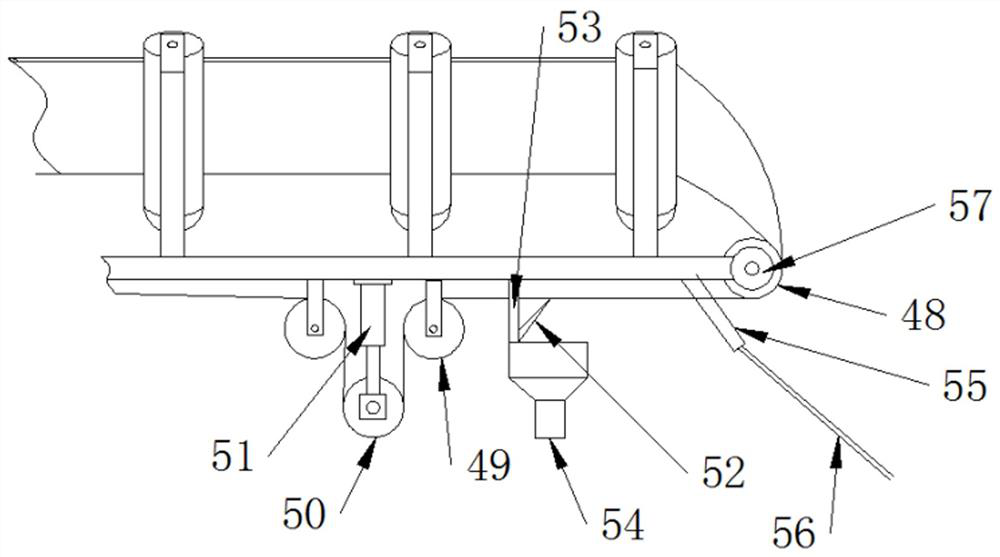

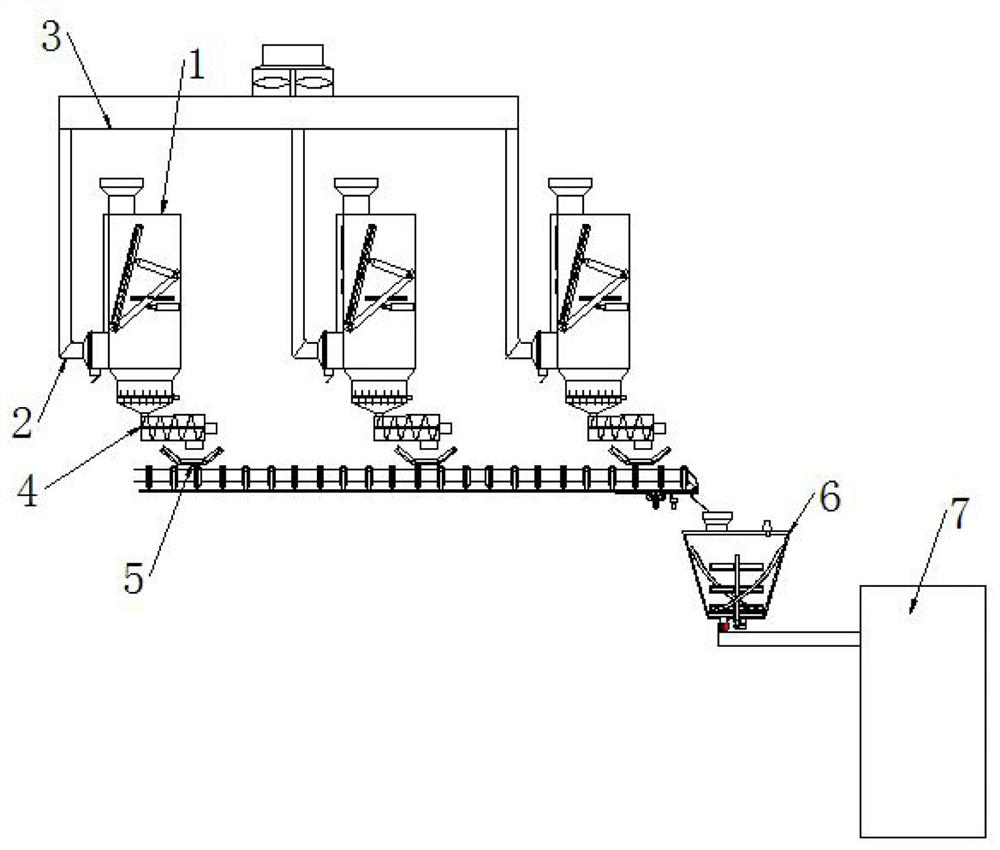

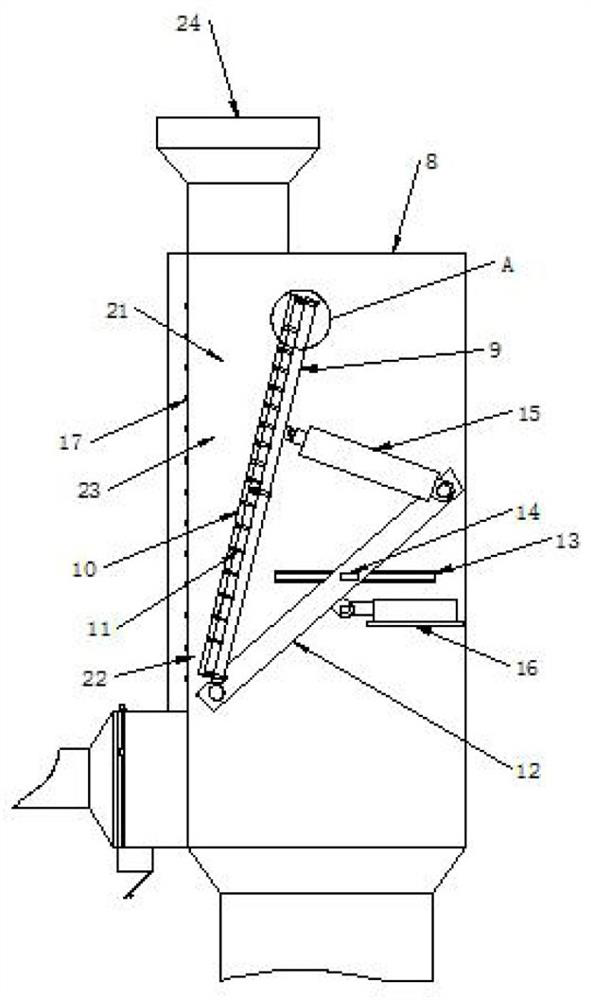

[0096] Such as Figure 1 to Figure 11 As shown, the steelmaking slag conveying production line includes a plurality of raw material main conveying devices 1 arranged side by side, and each raw material main conveying device 1 is respectively provided with a dust conveying device 2, and several dust conveying devices 2 are jointly connected to the ventilation conveying pipeline 3 Above, the outlet of each raw material main conveying device 1 is connected with a material quantitative conveying device 4, the outlets of several material quantitative conveying devices 4 are connected with a converging conveying device 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com