Alkylation method

A technology of alkylation and alkylation reaction, which is applied in the field of alkylation, can solve the problems of increasing the amount of alkyl sulfuric acid, and achieve the effects of reducing acid consumption, reducing side reactions, and improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

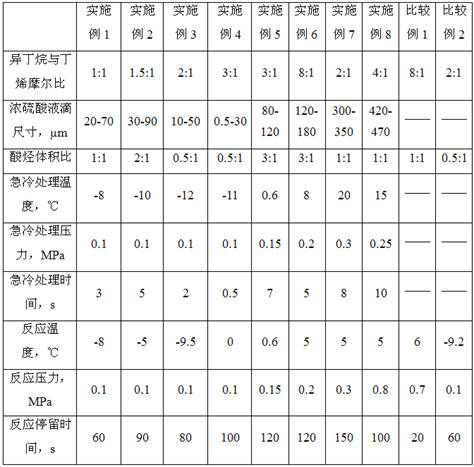

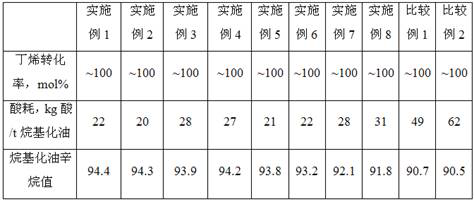

[0023] Mix isobutane and butene gas to form a mixed raw material gas, disperse 96% concentrated sulfuric acid into droplets, mix the mixed raw material gas with concentrated sulfuric acid droplets, and then perform rapid cooling treatment, and keep it for a certain period of time under the condition of rapid cooling treatment , so that the mixed feed gas is condensed with concentrated sulfuric acid droplets as the nucleus, and then adjusted to the reaction conditions, so that the material undergoes an alkylation reaction to generate alkylated oil. After the reaction is completed, the sulfuric acid and alkylated oil are separated, and the sulfuric acid is returned to For alkylation reactions.

[0024] See Table 1 for the mixing ratio of isobutane and butene in the reactions of each embodiment, the droplet size of concentrated sulfuric acid, the volume ratio of acid to hydrocarbon, the quenching conditions and the specific reaction conditions

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com