Low-tar and low-phenolic-water multi-medium fixed bed gasifier

A fixed-bed gasifier and low-tar technology, applied in gasification process, gasification device details, petroleum industry, etc., can solve the problems of increasing the amount of cooling and scrubbing gas, increasing the difficulty of extraction, increasing the amount of phenol-containing wastewater treatment, etc., reaching The purification process is simple, and the effect of improving gasification efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the solutions of the embodiments of the present invention, the embodiments of the present invention will be further described in detail below in conjunction with the drawings and implementations.

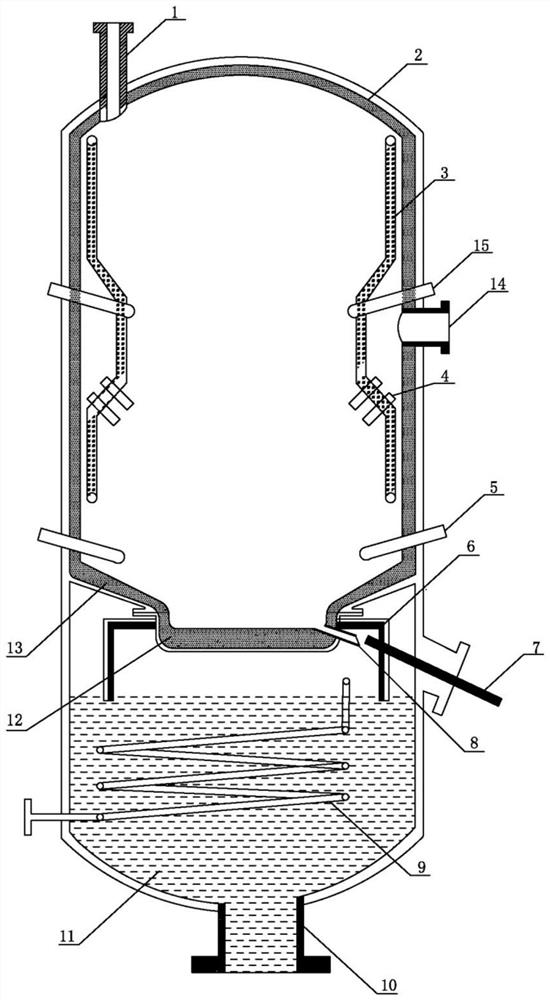

[0025] Such as figure 1 As shown, the low-tar, low-phenol water multi-media fixed-bed gasifier provided in this embodiment includes: a furnace body 2, a feed inlet 1 is arranged at the upper end of the furnace body, and a slagging outlet 10 is arranged at the bottom of the furnace body 2, through which It discharges the condensed slag out of the gasifier.

[0026] In the embodiment of the present invention, a membrane water-cooled wall 3 arranged along the axial direction of the furnace body 2 is arranged inside the furnace body 2 . An annular cavity is formed between the side wall of the membrane water cooling wall 3 and the side wall of the furnace body 2, and a steady flow gas spray gun 15 and a small high t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com