V-N microalloyed 550 MPa hot-rolled thick-wall H-shaped steel and production process thereof

A technology of micro-alloying and production technology, which is applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of uneven performance of H-shaped steel section, small deformation of joints, large deformation of web, etc. Achieve the effect of increasing the precipitation strength, making up for the difference in strength, and the effect of high rolling temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

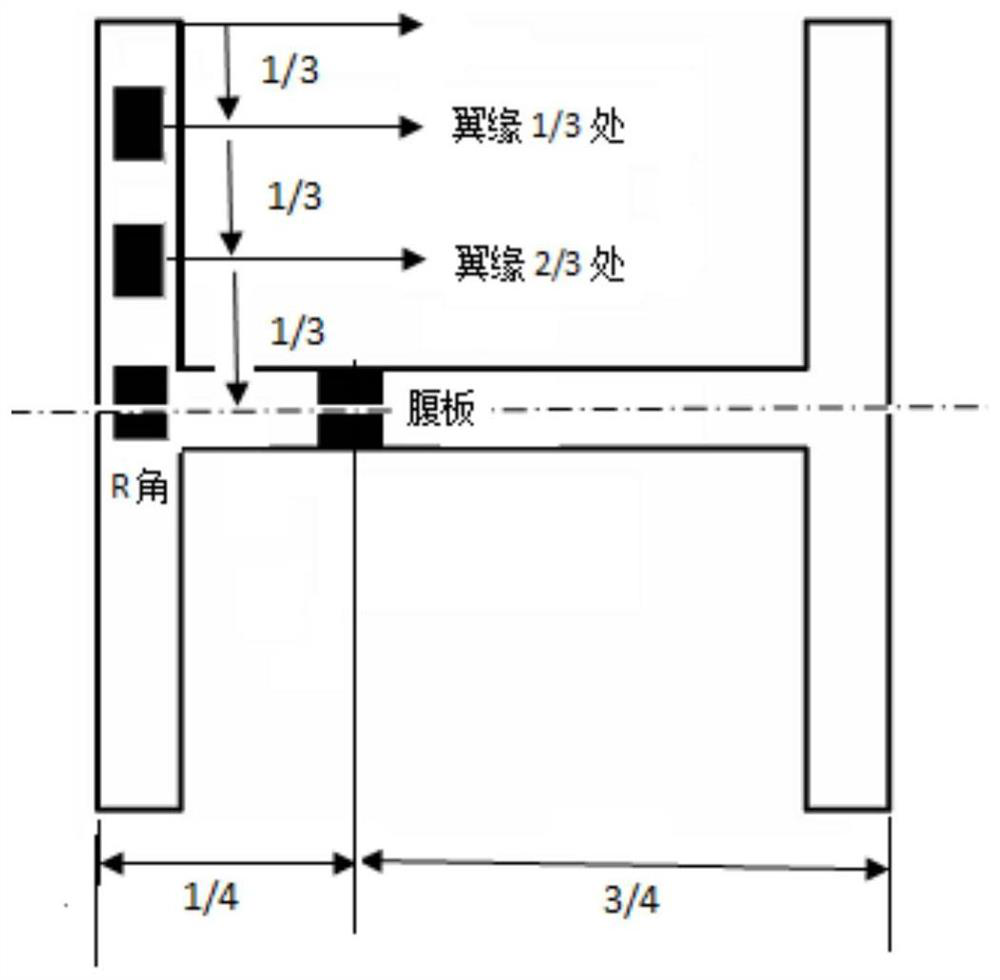

[0056] Various thick-walled H-beams of Examples 1 to 4 and Comparative Examples 1 to 4 were industrially produced. Among them, Example 1 and Comparative Example 1 are made into thick-walled H-beams with a specification of 200mm×400mm×20mm×35mm (length×width×web thickness×flange thickness); Example 2 and Comparative Example 2 are made into a specification of Thick-walled H-beams of 400mm×400mm×20mm×35mm (length×width×web thickness×flange thickness); Example 3 and Comparative Example 3 are made into a specification of 900mm×300mm×18mm×34mm (length×width×web Thick-walled H-beam with plate thickness×flange thickness); Example 4 and Comparative Example 4 were made into thick-walled H-beam with specifications of 1000mm×300mm×19mm×36mm (length×width×web thickness×flange thickness).

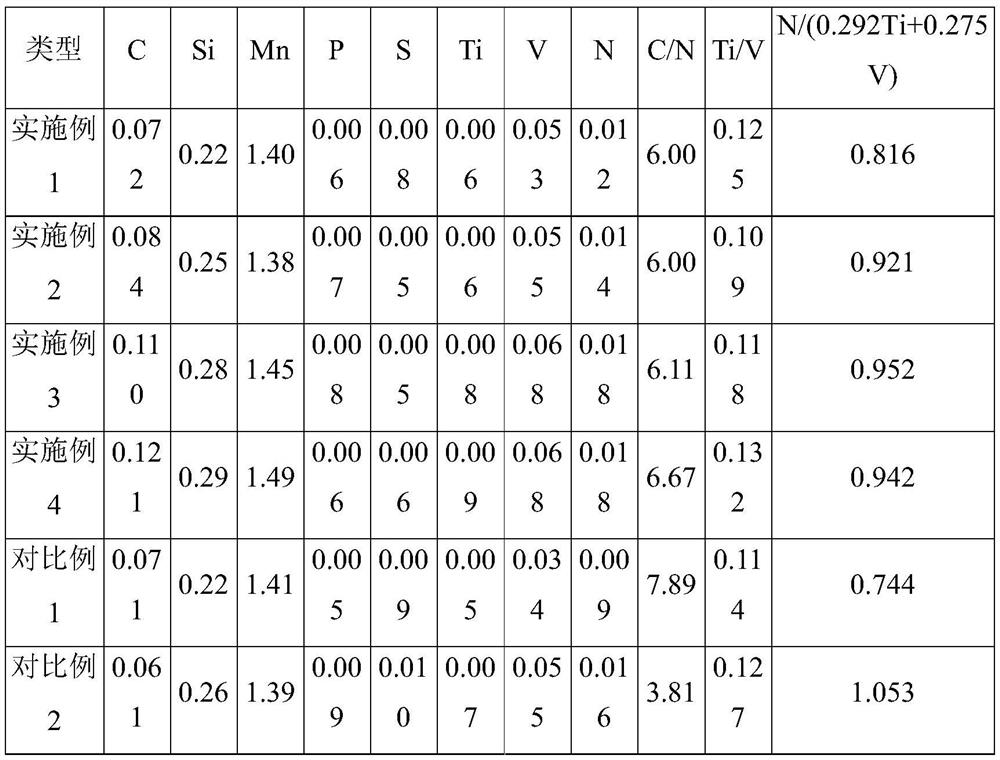

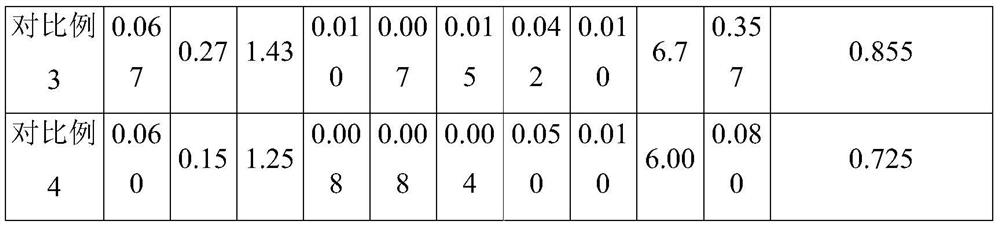

[0057] Table 1 Chemical composition (wt%) of thick-walled H-beams of the embodiment and the comparative example

[0058]

[0059]

[0060] As can be seen from Table 1, the chemical compositions of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com